Reaction equipment with quantitative charging and quantitative charging method thereof

A technology of reaction equipment and reactor, applied in chemical instruments and methods, feeding devices, chemical/physical/physicochemical processes, etc., can solve the problems of inconvenient quantitative control and non-continuous operation, so as to reduce design costs and ensure The effect of reaction temperature and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

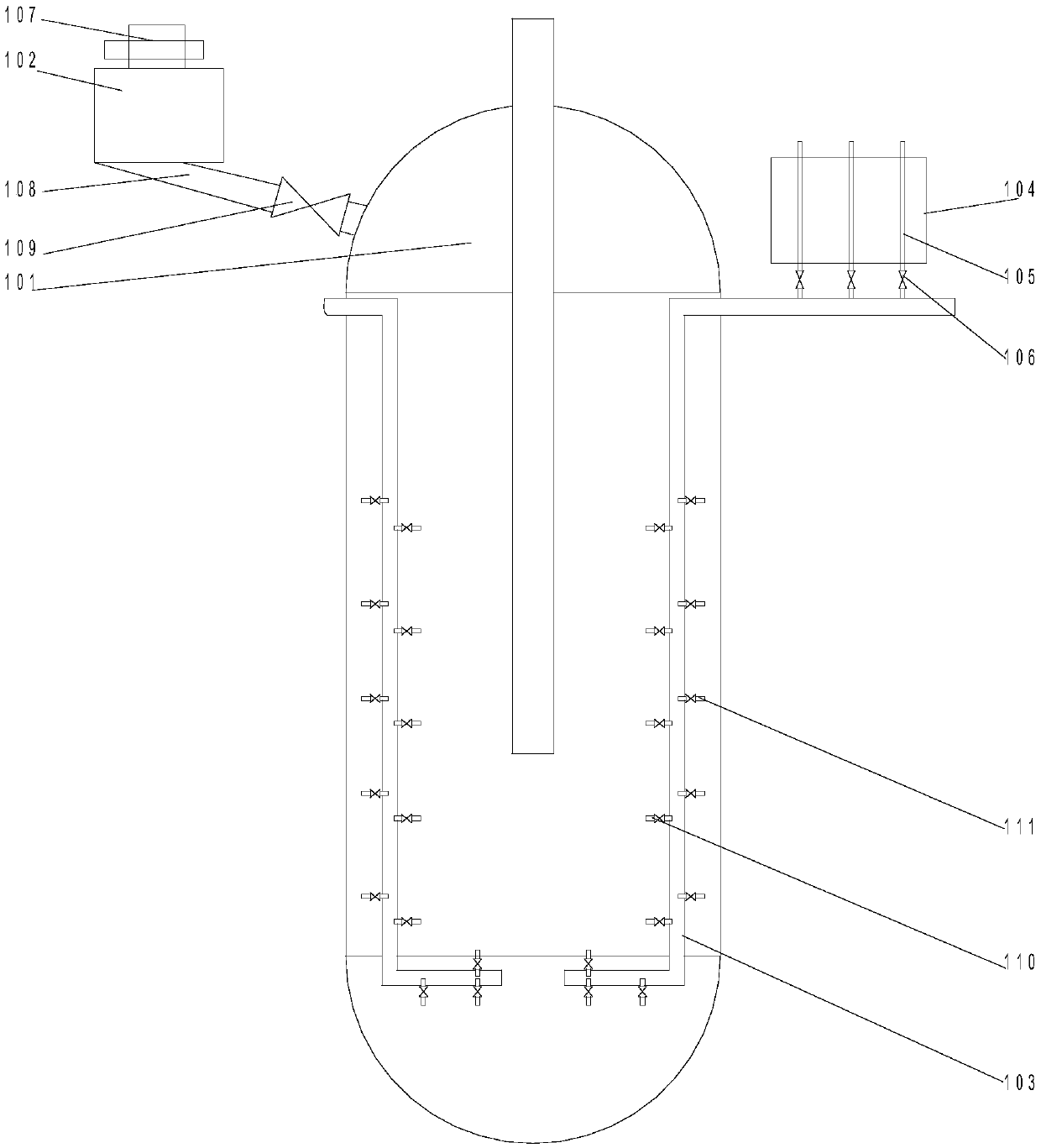

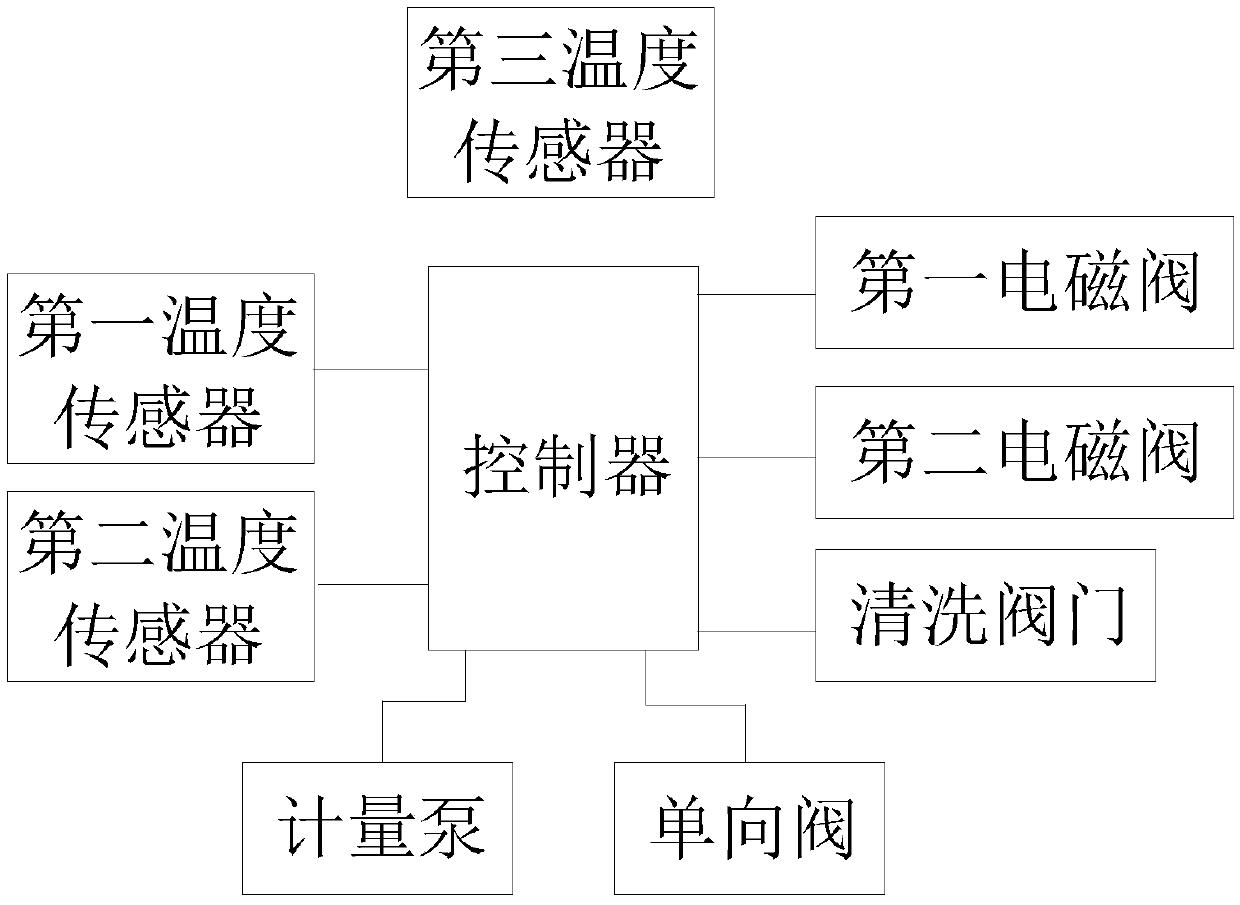

[0022] Such as figure 1 As shown, a reaction equipment for quantitative feeding includes a reaction kettle 101 and a feeding device 102 arranged on one side of the reaction kettle 101, and a circulation pipeline 103 is arranged inside the reactor 101, and the circulation pipeline 103 Input from one side of the reactor 101 and output from the other side, a preheating device 104 is arranged outside the reactor 101, and a preheating pipe 105 is arranged inside the preheating device 104. The preheating pipe 105 is connected to the circulation pipeline 103 through the first solenoid valve 106, the feeding device 102 is provided with a feeding port 107, and the feeding port 107 is provided with a metering pump, so The feeding device 102 is connected to the reaction kettle 101 through the feeding pipe 108, the second solenoid valve 109 is arranged on the feeding pipe 108, and the single valves arranged at intervals are arranged on the circulating pipeline 103. Directional valve 110,...

Embodiment 2

[0028] Further, in order to better realize the present invention, the present invention also discloses a quantitative feeding method of reaction equipment, comprising the following steps:

[0029] S1: Input materials into the feeding device 102 through the feeding port 107, send a driving signal to the metering pump through the controller, and measure the total feeding weight during the feeding process;

[0030] S2: The controller sends a drive signal to the second solenoid valve 109 to open the second solenoid valve 109 and start to input materials into the reactor 101. During the process of completing the input of materials, the weight sensor measures the weight of the remaining materials and sends them to the controller. When the feed weight reaches the set value, the controller sends a drive signal to the second solenoid valve 109 to close the second solenoid valve 109;

[0031] S3: When it is necessary to heat the reactor, start the preheating device 104, detect the tempe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com