Online sewage cutting and smashing device

A crushing device and sewage technology, which is applied in the direction of grain processing, etc., can solve the problems of damage to hardware facilities, failure of secondary treatment, and low efficiency of primary treatment, so as to improve efficiency, prevent dirt from clogging, and ensure the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

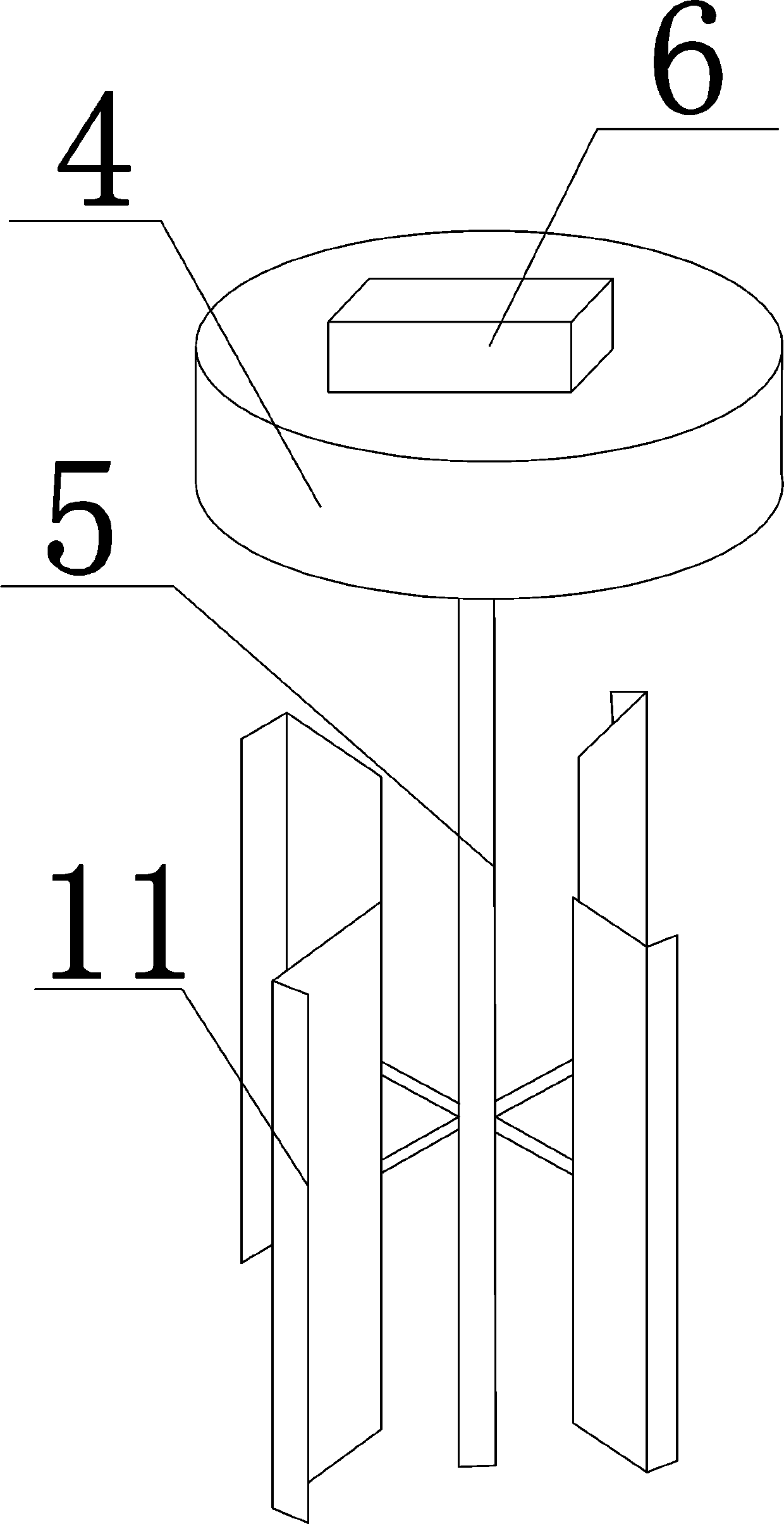

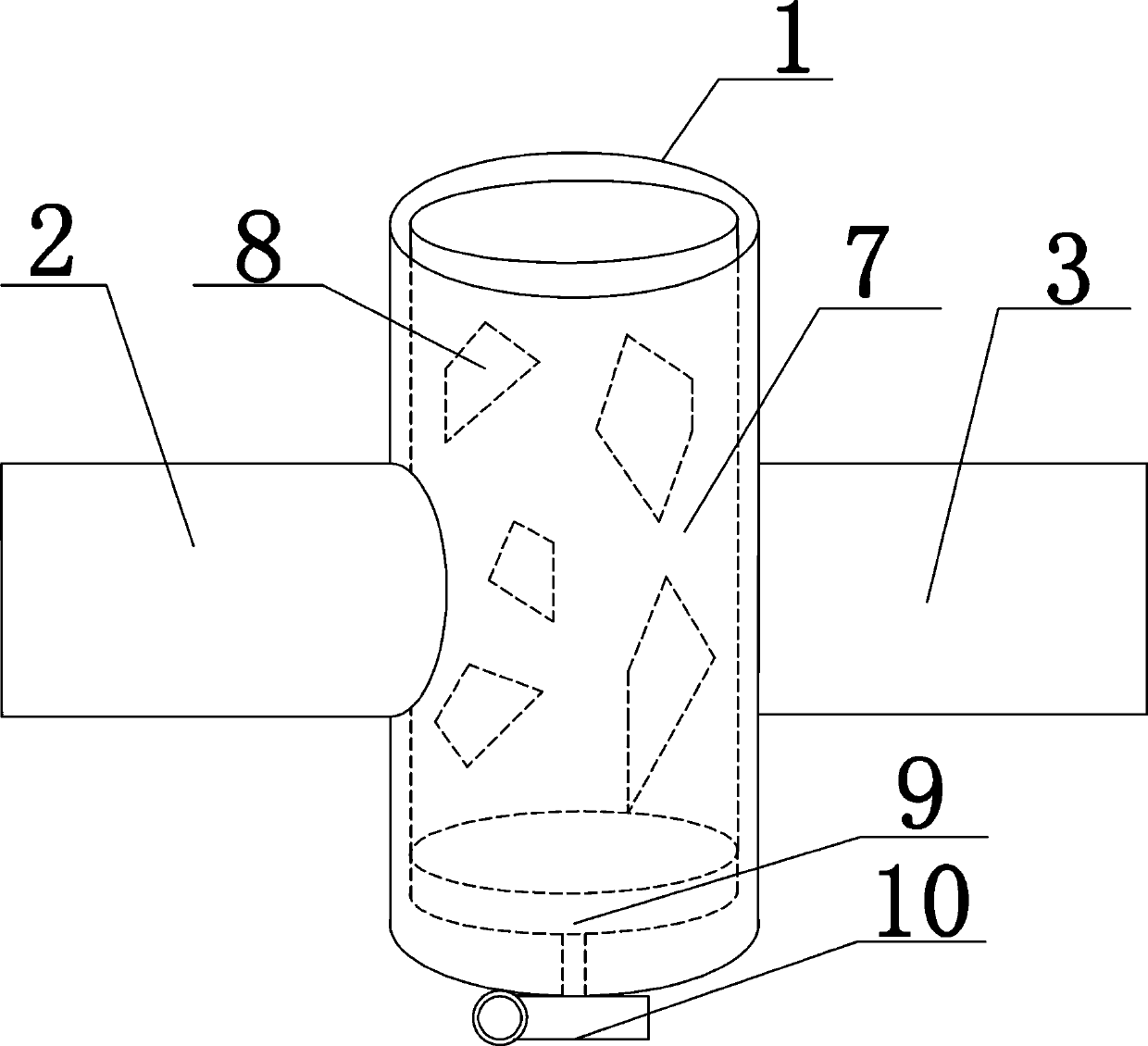

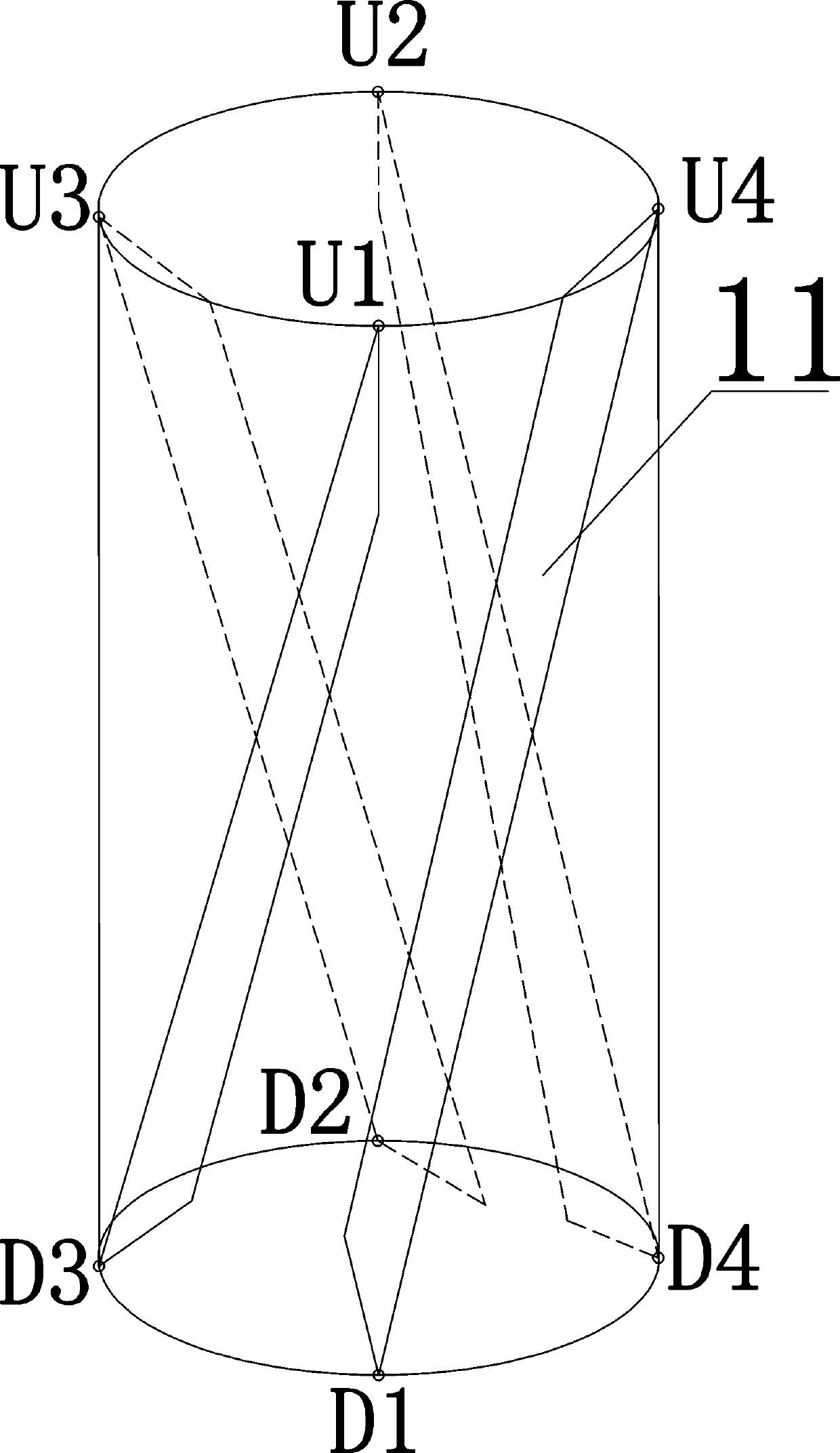

[0044] Cutting blade 11 is parallel to the inwall of cutting cylinder 7 and is arranged on the outside of rotating shaft 5 and the projection of cutting blade 11 coincides with rotating shaft 5 in the vertical direction, namely cutting blade 11 is longitudinally arranged, and when cutting cylinder 7 is cylindrical shape, cutting The blades 11 are perpendicular to the horizontal direction, and when the cutting cylinder 7 is in the shape of a rounded truncated cone, the plurality of cutting blades 11 are in the shape of a rounded truncated cone as a whole. Taking the setting of four cutting blades 11 as an example, the upper bottom of the cylindrical or rounded frustum-shaped space where the cutting blades 11 are located is marked as U1, U2, U3, U4 at the four positions of the front, rear, left, and right sides, and the positions where the cutting blades 11 are located are marked as U1, U2, U3, and U4. The lower bottom of the cylindrical or rounded truncated space is marked as D1...

Embodiment 2

[0046] The cutting blades 11 are evenly distributed on the outside of the rotating shaft 5 parallel to the inner wall of the cutting cylinder 7 , and the projections of several cutting blades 11 in the horizontal direction are joined end to end to form a circle. When the projections of several cutting blades 11 in the horizontal direction are connected end to end to be a circle, the cutting blades 11 must be arranged obliquely. For example, four cutting blades 11 are set. The bottom is marked as U1, U2, U3, and U4 at the four positions of the front, rear, left, and right, and the lower bottom of the cylindrical or rounded frustum-shaped space where the cutting blade 11 is located is marked as D1, D2, and D3 at the four positions of the front, rear, left, and right. , D4, then the first cutting blade 11 connects U1 and D3, the second cutting blade 11 connects U3 and D2, the third cutting blade 11 connects U2 and D4, and the fourth cutting blade 11 connects U4 and D1.

[0047] I...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com