Dip-soldering pin shearing machine

A foot cutting machine and dip soldering technology, which is applied in metal processing, electrical component assembly and printed circuit, etc., can solve the problems of low work efficiency, unclean board surface, low efficiency, etc., and achieve high work efficiency, clean surface, and improved The effect of production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

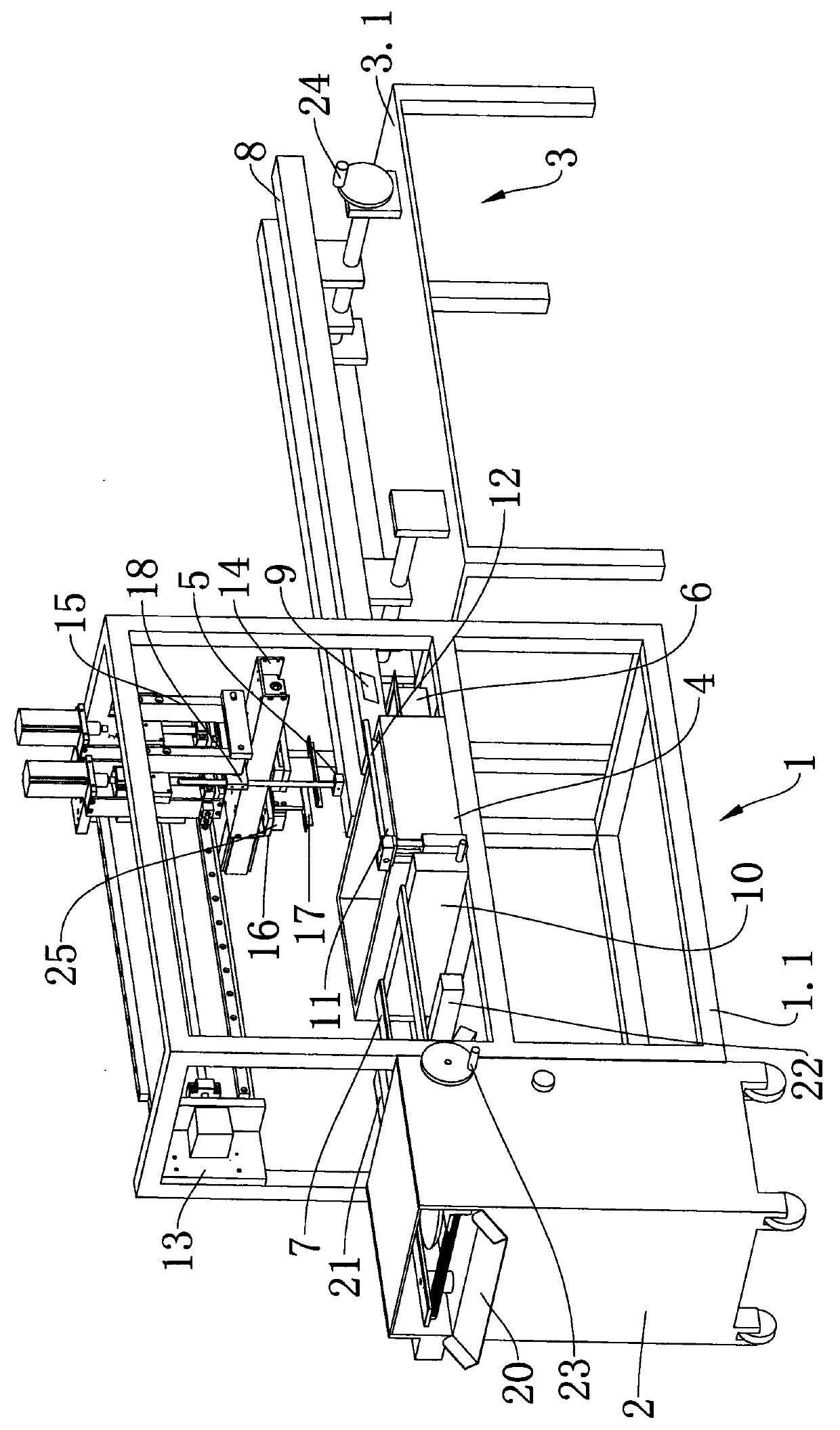

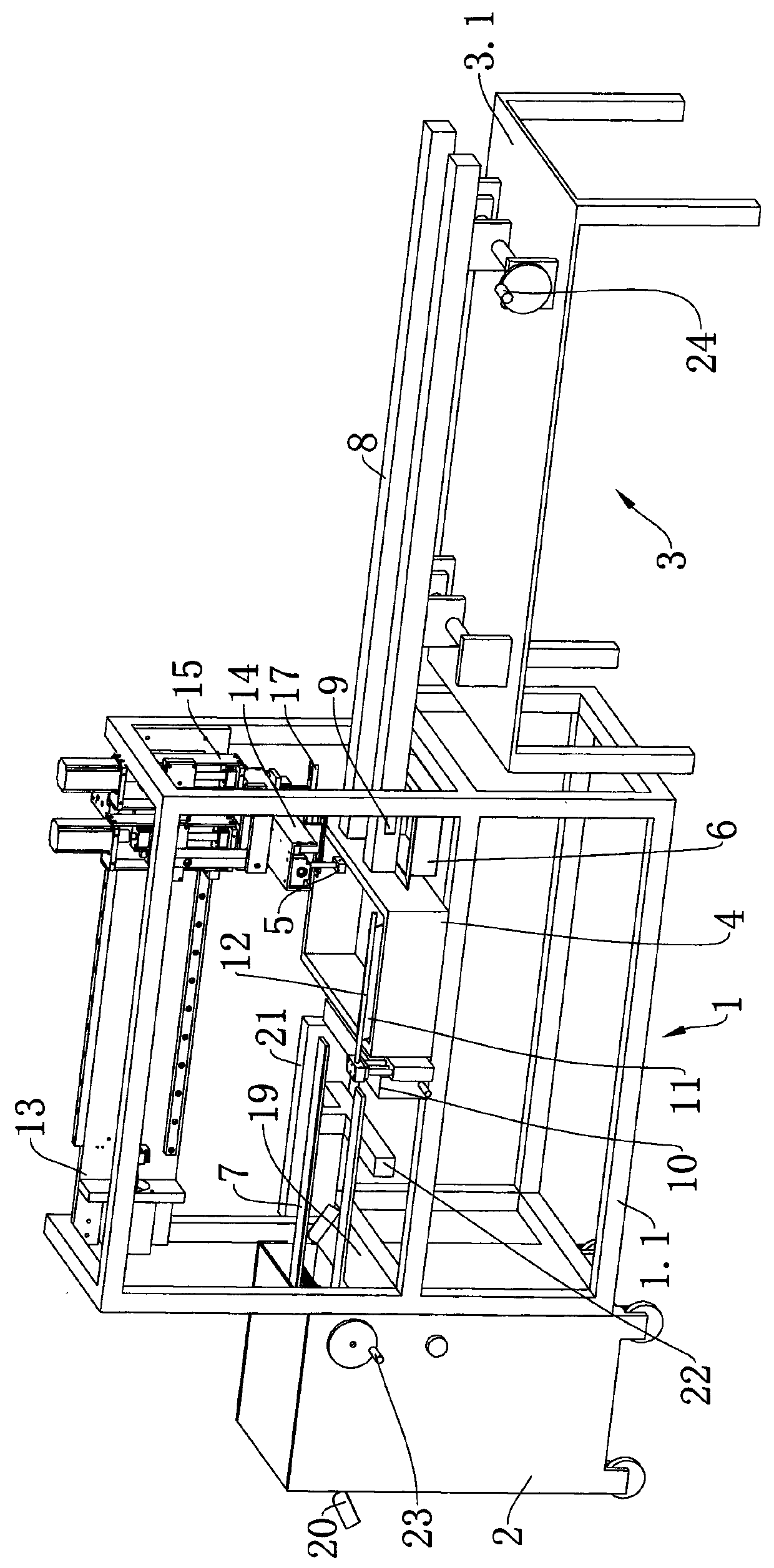

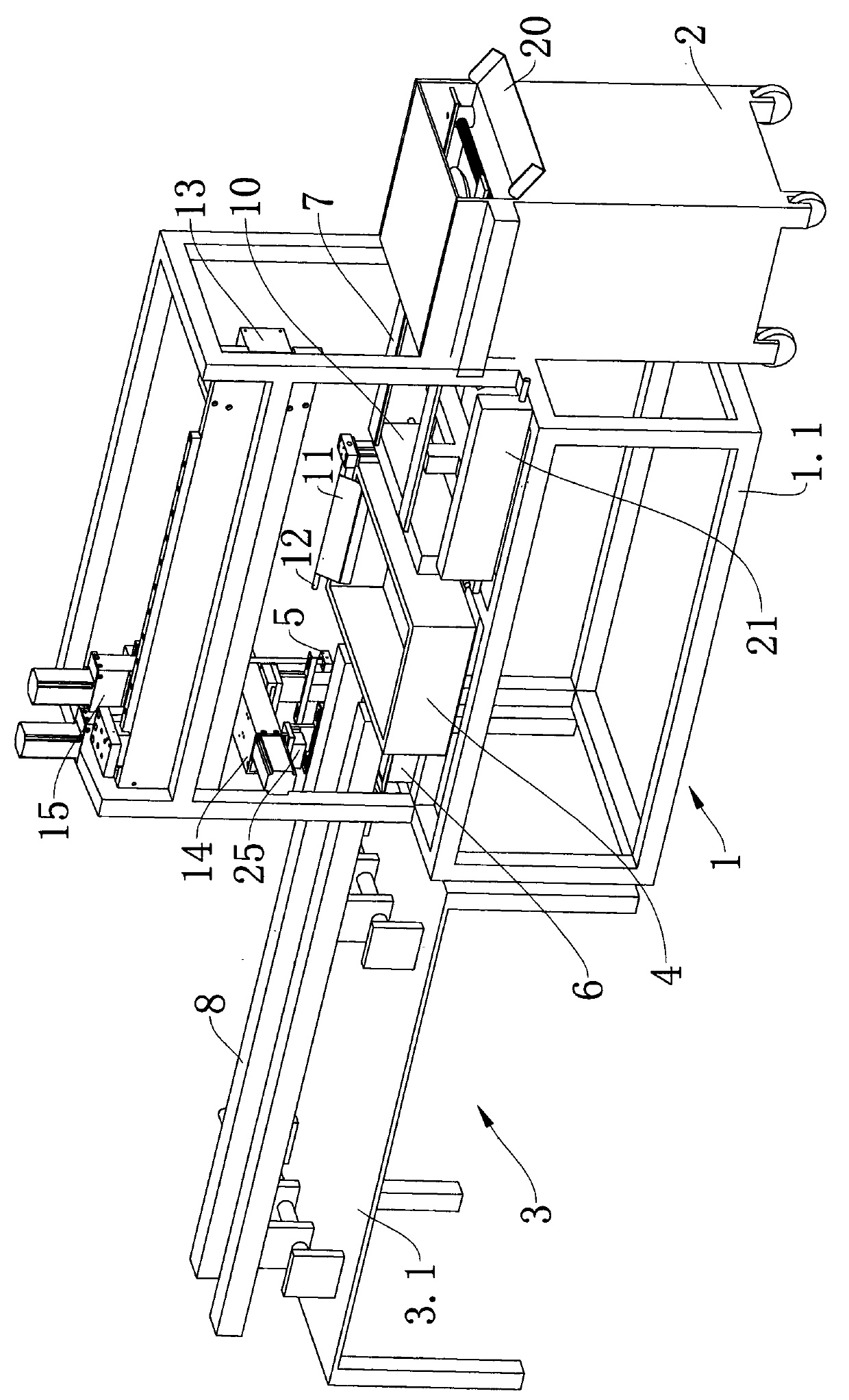

[0022] In order to understand the technical scheme of the present invention more intuitively and completely, the non-limiting feature descriptions are as follows in conjunction with the accompanying drawings of the present invention:

[0023] Such as Figure 1-Figure 4 As shown, the dip soldering and cutting machine includes a dip welding machine 1, a cutting machine 2 and a connecting platform 3, and the cutting machine 2 and the connecting platform 3 are respectively arranged on both sides of the dip welding machine 1, and the dip welding machine 1 includes Frame 1.1, the middle position of frame 1.1 is equipped with dip soldering furnace 4, dip soldering furnace 4 is connected with tin scraping device, and frame 1.1 is also equipped with dip soldering swing mechanism, clamping mechanism, liquid level detection probe 5 and automatic The spray furnace 6 and the foot cutting machine 2 are provided with a foot cutting machine guide rail 7, and one end of the foot cutting machin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com