A device for automatically aligning, correcting and positioning a camshaft

A camshaft and automatic technology, applied in the control of workpiece feed movement, grinding machine parts, grinding machines, etc., can solve the problems of high clamping skills of operators, unstable parts processing quality, positioning keyway positioning errors, etc. , to achieve the effects of wide application range, simplified installation requirements, and high angular positioning accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

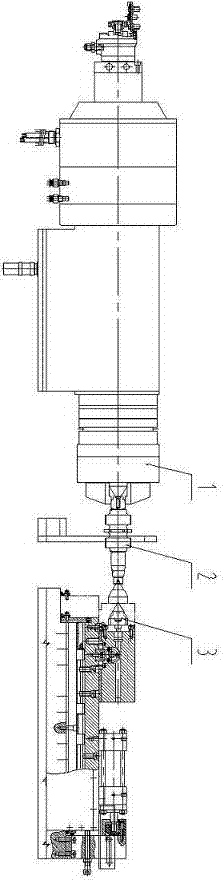

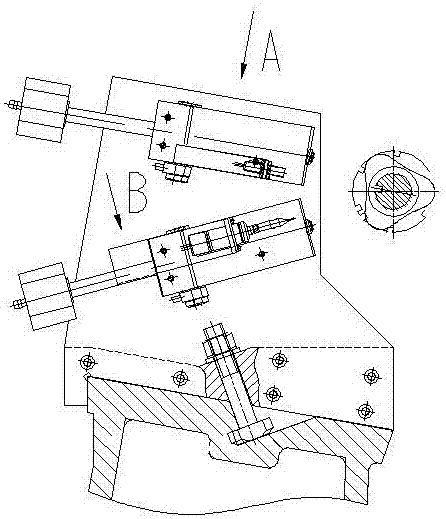

[0017] The specific embodiment of the present invention is as figure 1 , figure 2 shown.

[0018] The camshaft grinding machine of this embodiment is composed of a floating hydraulic chuck 1 on the headstock of the machine tool, an automatic alignment and deviation correction positioning device, a workpiece 2, and a tailstock 3 of the machine tool. The automatic alignment and deviation correction positioning device is installed between the headstock and tailstock of the machine tool. The angle coarse positioning hydraulic cylinder 6 and the angle fine positioning hydraulic cylinder 10 are installed on the connecting plate 5 .

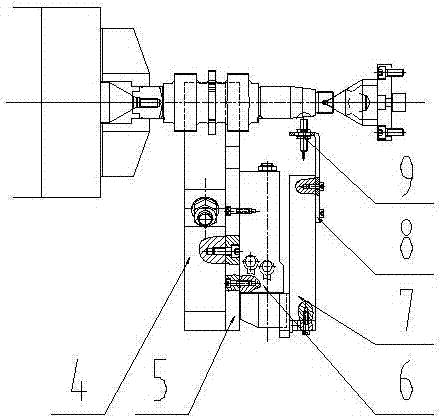

[0019] Angle coarse positioning mechanism such as image 3 As shown, the rough angle positioning mechanism is composed of a rough angle positioning hydraulic cylinder 6, a rough positioning fixed block 7, a rough positioning sensor mounting support 8, and a rough positioning non-contact position sensor 9. The coarse positioning fixed block 7 is ins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com