Braking vane provided with rubber bumps and manufacture method of braking vane

A technology of rubber bumps and manufacturing methods, applied in the directions of brakes, brake components, vehicle parts, etc., can solve problems such as ineffective braking systems, vehicle stops, accidents, etc., to increase the sense of safety and driving confidence, and eliminate disadvantages. The psychological effect, the effect of convenient installation and replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

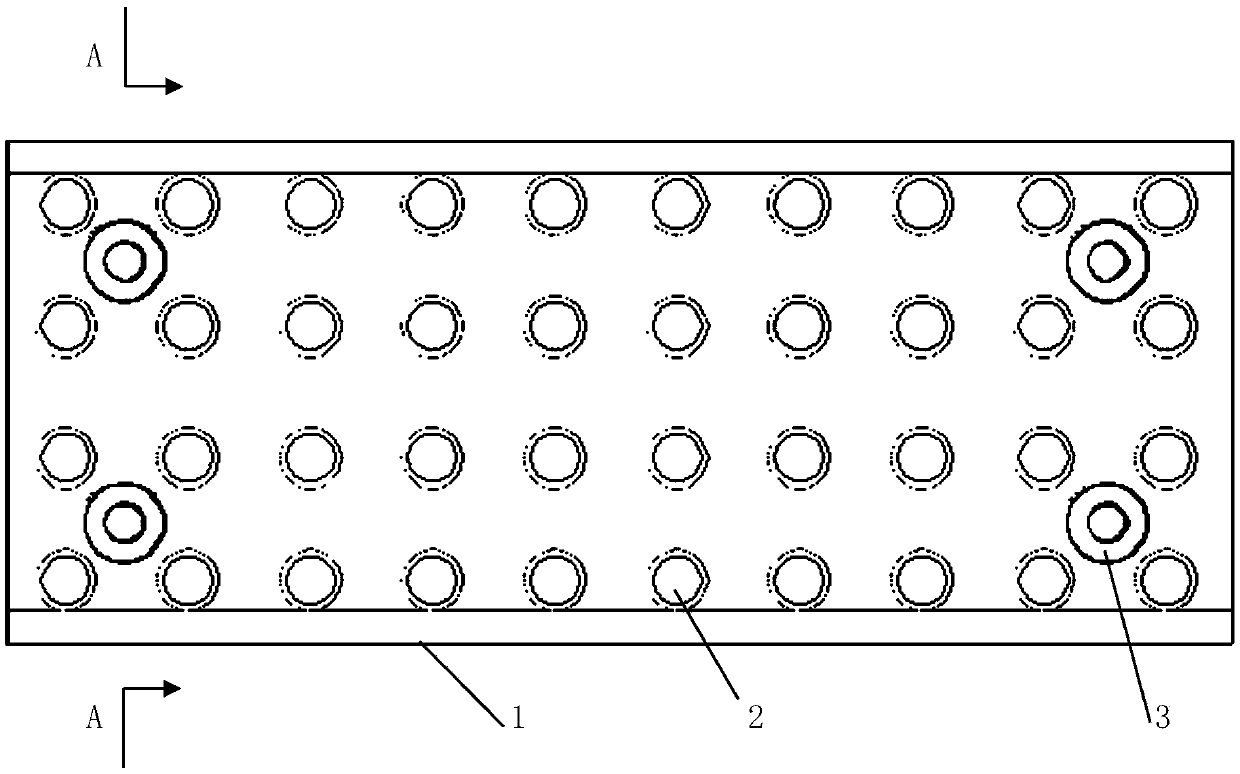

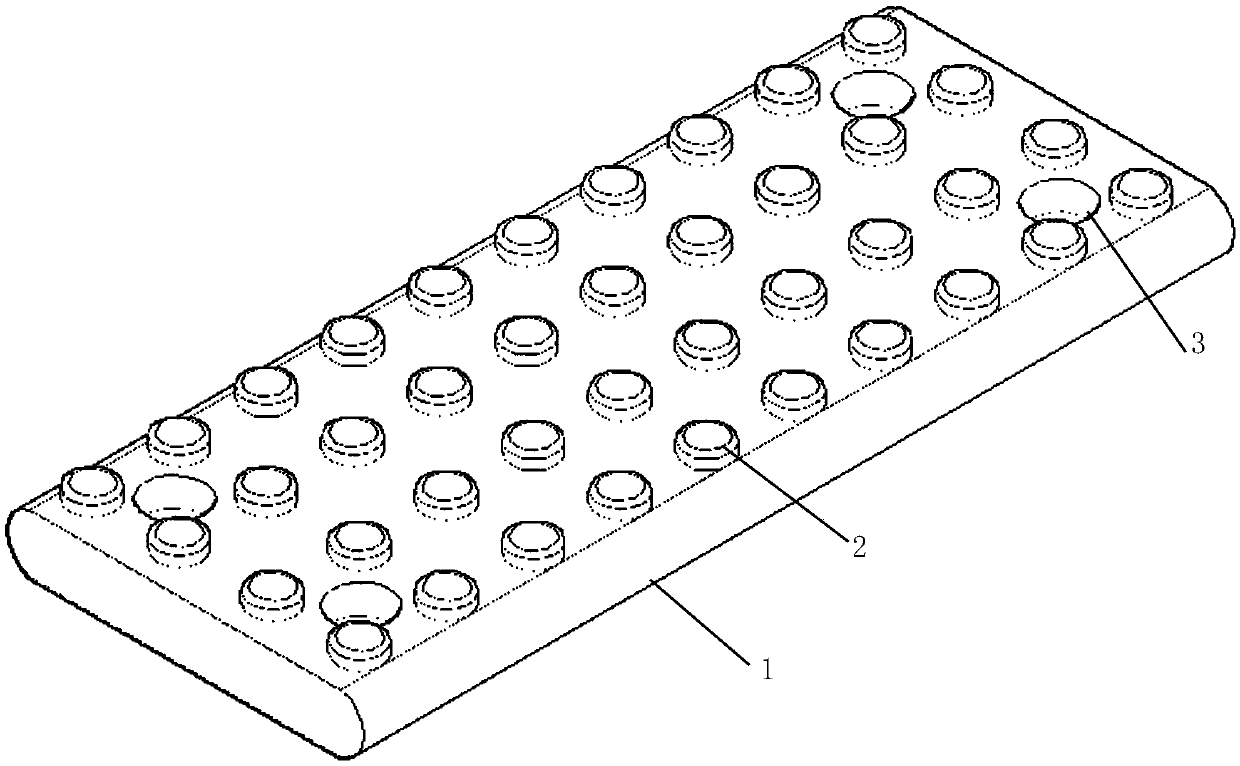

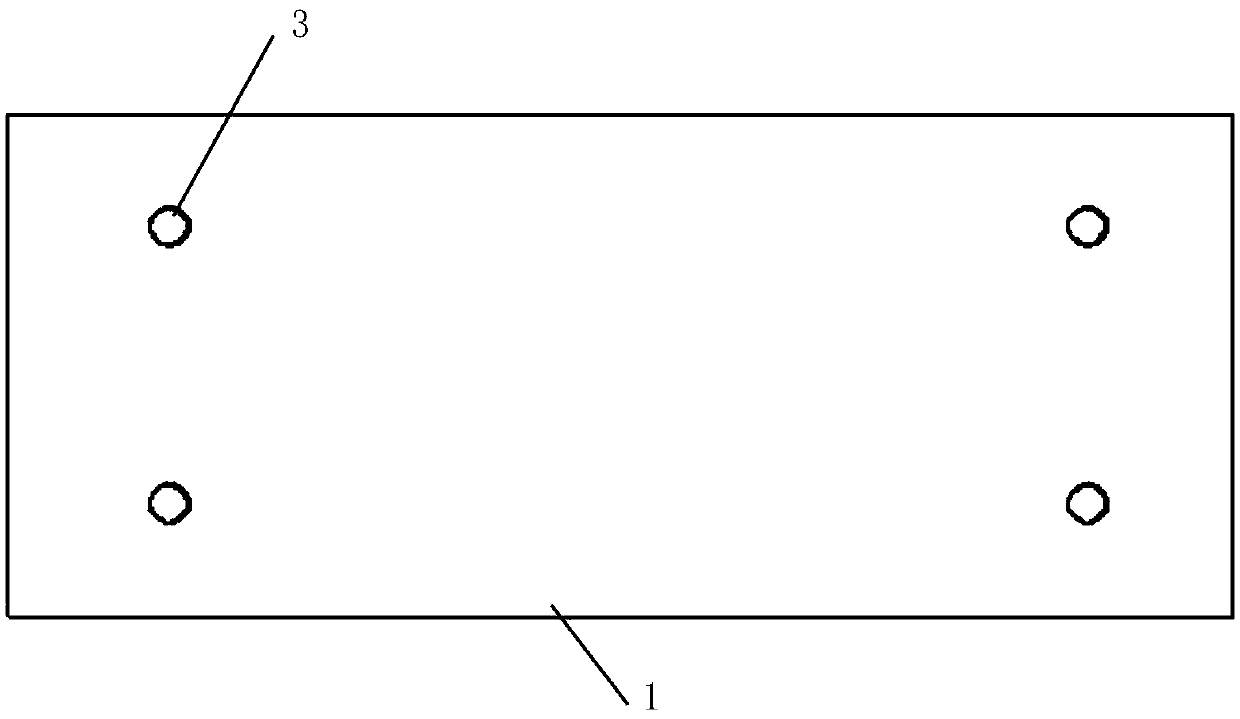

[0027] Embodiment 1: refer to attached Figure 1-6 , a brake pad 1 with rubber bumps of the present invention includes a board body, and is characterized in that: a grid 4 is provided in the board body, rubber bumps 2 are arranged on the board body, and four corners of the board body are provided with There are screw holes 3 or buckle slots.

[0028] In a further preferred solution, the plate body is rectangular, the screw hole 3 is a countersunk hole, and the bolt 8 is connected to the brake plate fixing frame 7 through the screw hole 3, or connected to the brake plate fixing frame through a buckle slot.

[0029] In a further preferred solution, the rubber bumps 2 are evenly distributed on the surface of the board body, the diameter of the bumps 2 is 10-30mm, and the height is 10-20mm.

[0030] In a further preferred solution, the grid 4 is a criss-cross nylon fiber grid or steel wire grid.

[0031] This embodiment also discloses a method for manufacturing a brake pad with ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com