Method for integrally mounting railway accessories with packing box

A technology for packaging boxes and accessories, applied to drawer containers and other directions, can solve the problems of wasting manpower and material resources, consuming a lot of time, and redundant parts, and achieving the effects of saving transportation, improving installation efficiency, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

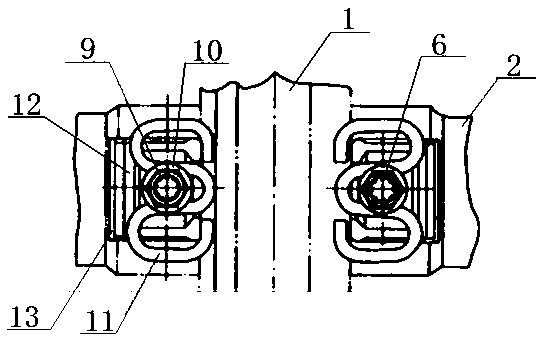

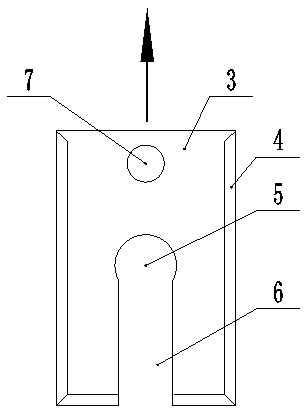

[0028] This embodiment provides a packaging box for railway accessories, such as figure 1 and figure 2 As shown, the railway accessories are an accessory group A installed between rails 1 and crossties 2; the packaging box includes a cover and a drawer 3, the cover includes a cavity and a bottom 4, and the shape of the cavity is According to the state of use of the accessory group A installed between the rail 1 and the sleepers 2, any accessories in the accessory group A cannot be moved in the packing box; figure 2 As shown, the bottom 4 is a slot parallel to the drawer 3, the drawer 3 is stuck in the slot to pack the accessory group A in the packaging box, and the drawer 3 can be arranged along the opposite The two card slots move linearly, figure 2 The arrow shown indicates the moving direction of the drawing body 3; the drawing body is provided with a positioning hole 5, and the positioning hole 5 is stacked with the holes of each railway fitting included in the fittin...

Embodiment 2

[0036] This embodiment provides a method for installing railway accessories, using the packaging box described in Embodiment 1 to cooperate with the installation, including the following steps:

[0037] S1. Stack the accessory group A according to the state of use installed between the rails and the sleepers, and pack them in the packing box;

[0038] S2. Put the packaging box containing the accessory group A on the road stud through the positioning hole;

[0039] S3. Pull out the drawing body, and the drawing body is pulled out along the slot;

[0040] S4. Taking out the cover;

[0041] S5. The accessory set A includes fasteners, and the fasteners and spikes are tightened to complete the installation of the accessory set A.

[0042] In the step S1, the accessory set A is placed in the packaging box in advance through an assembly line.

[0043] The accessory group A includes nuts, gaskets, elastic bars, spacers and buffer pads. After the gaskets, elastic bars, spacers and buf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com