Finished product feeding device for production of junction boxes

A junction box and finished product technology, applied in the directions of transportation and packaging, conveyor objects, etc., can solve the problems of affecting the efficiency and quality of patch products, low efficiency of manual cutting, hand burns, etc., to achieve simple structure, convenient operation, The effect of improving efficiency and quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

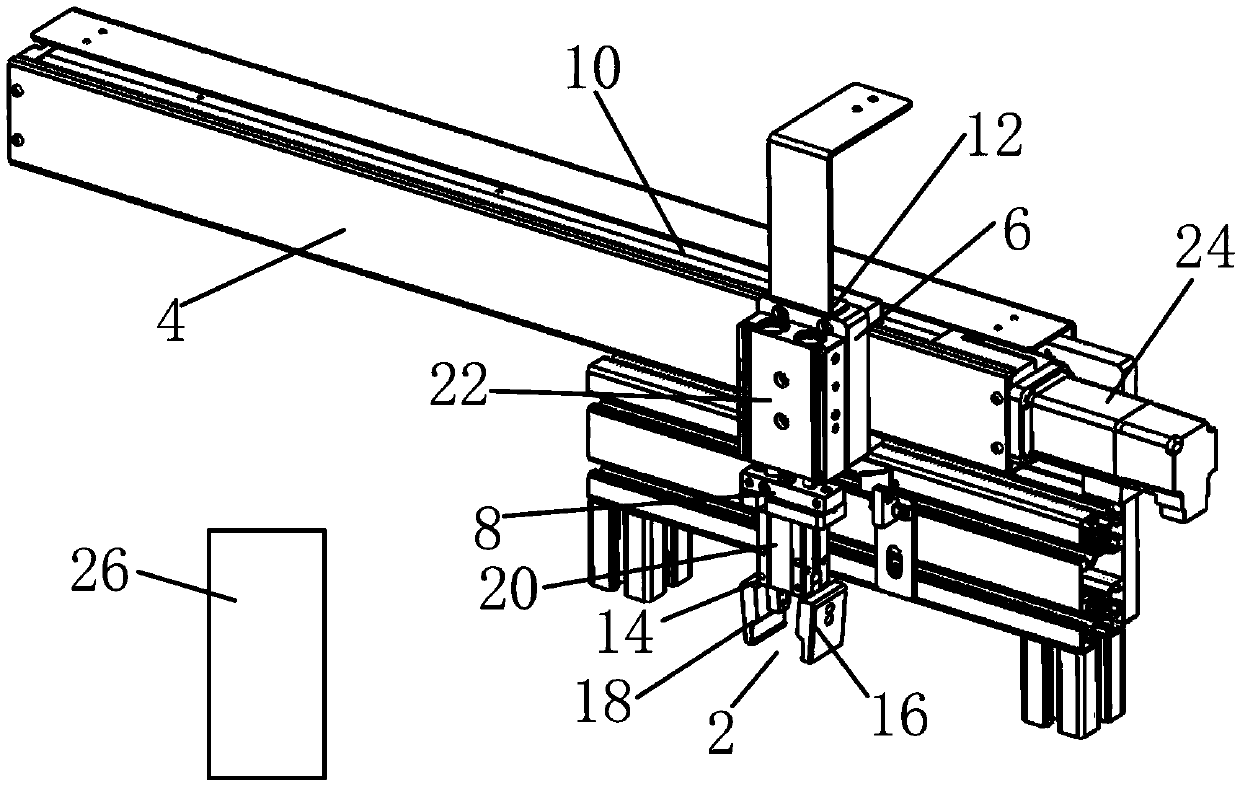

[0016] Such as figure 1 As shown, this embodiment discloses a finished product unloading device for junction box production, including a sliding assembly and a gripper 2 fixed thereon. The sliding assembly includes an X-axis sliding table 4 and a Z-axis sliding table 6 And the sliding seat 8, the X-axis slide table 4 is provided with a first linear slide rail 10 extending along the X-axis direction, and the Z-axis slide table 6 is provided with a second linear slide rail extending along the Z-axis direction 12. The Z-axis slide table 6 is set on the X-axis slide table 4 that can slide along the first linear slide rail 10, and the slide seat 8 is set on the Z-axis slide table that can slide along the second linear slide rail 12 6, the grasping hand 2 is fixed on the sliding seat 8. Specifically, the Z-axis slide table 6 and the slide seat 8 move in the first linear slide rail 10 and the second linear slide rail 12 under the drive of the first slide cylinder 22 and the second s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com