Shunt system

A shunt system and structuring technology, applied in the direction of machines/engines, mechanical equipment, steam engine devices, etc., can solve the problem of increasing the overall space of power generation equipment, and achieve the effect of eliminating fire risks and reducing floor space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

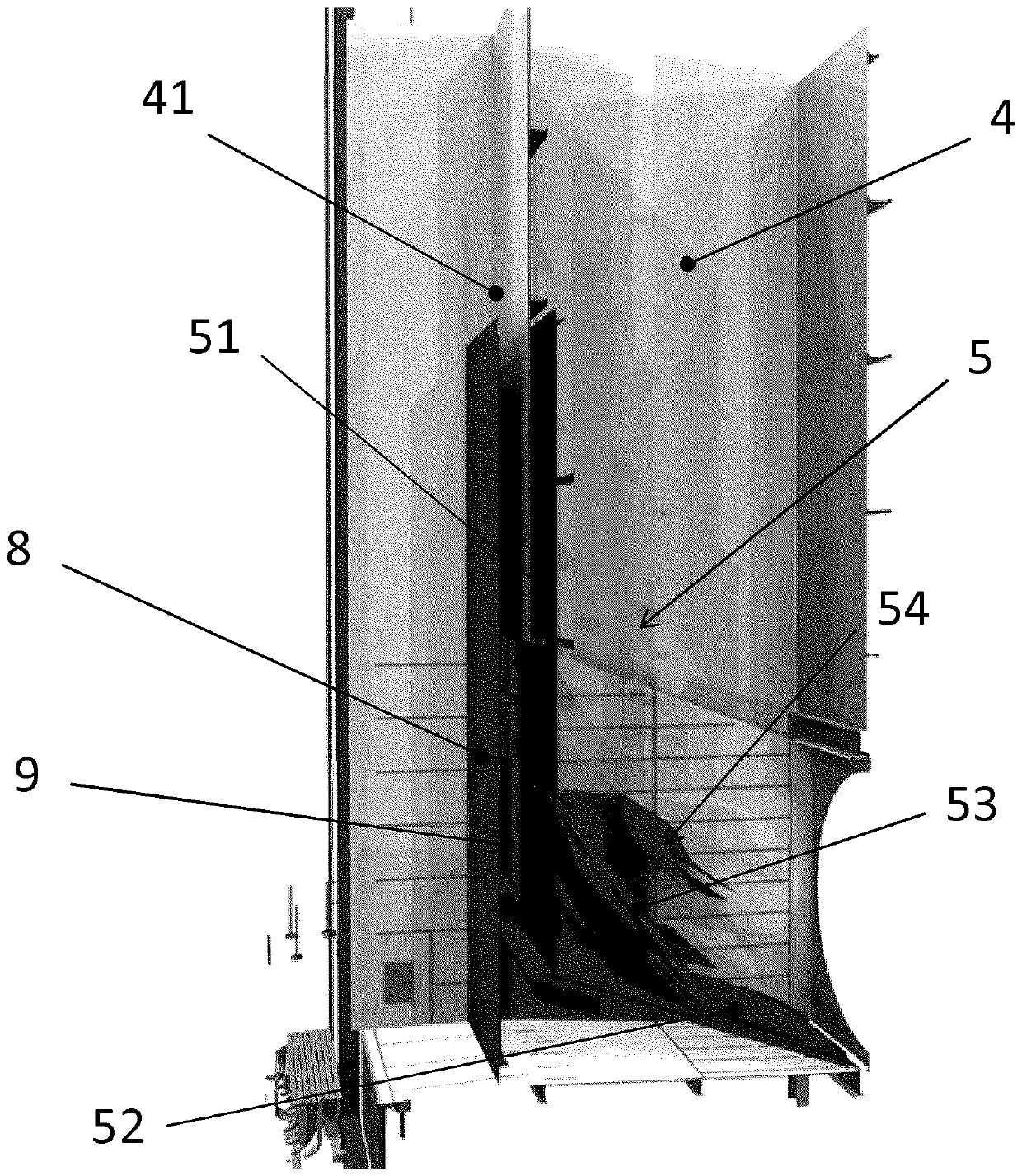

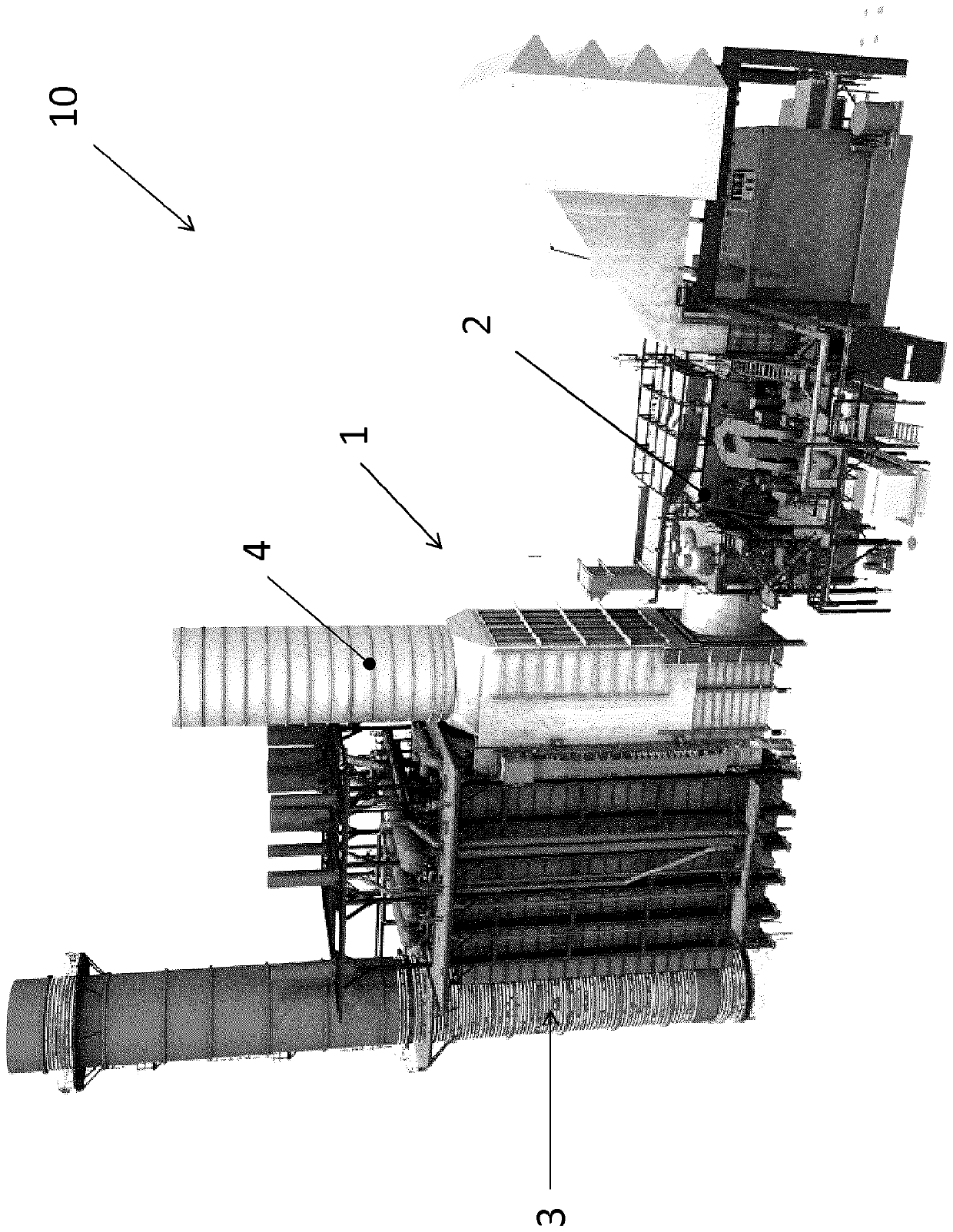

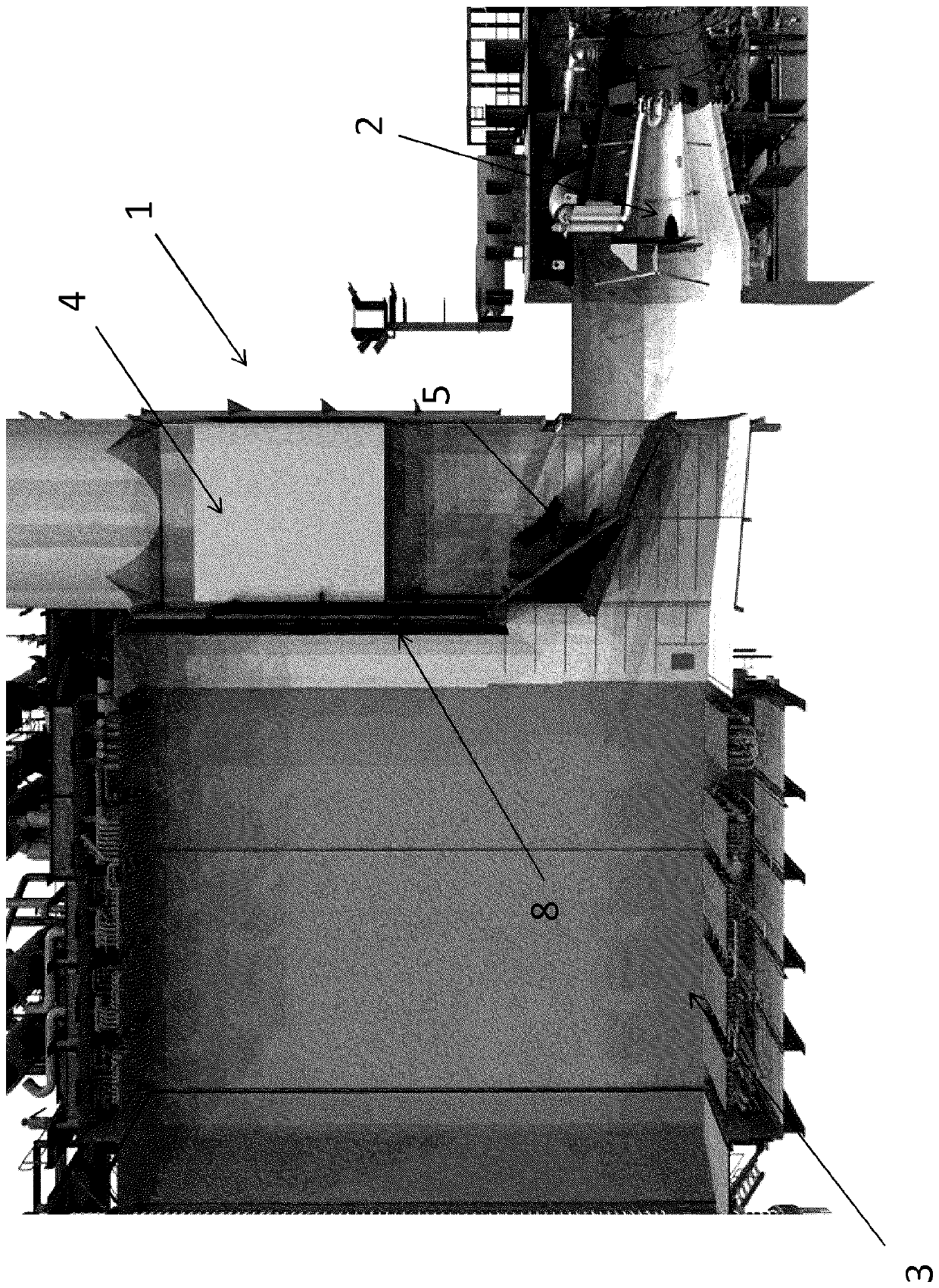

[0025] see figure 1 , generally shows a combined cycle plant 10 . The combined cycle plant includes a gas turbine plant 2 and a heat recovery steam generator 3 (hereinafter referred to as HRSG) associated with the steam power plant, which uses hot exhaust gas from the gas turbine to heat water and generate steam . The combined cycle plant comprises a bypass system 1 integrated within the inlet duct structure of the HRSG below the bypass chimney part indicated with reference number 4 .

[0026] More specifically, see the next figure 2 , the hot exhaust gas flowing out of the gas turbine plant 2 from the exhaust duct 21 is allowed to enter the split system 1 . The split system 1 then refines the gas and directs it to the upper bypass stack 4 if single cycle and / or maintenance operations are required, or allows it to enter the HRSG 3 if combined cycle is required. For this purpose, the split system 1 is movable internally between a single cycle closed position where hot exha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com