Mooring type fastening assembly

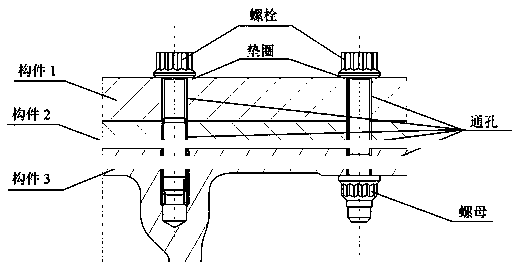

A fastening component and mooring technology, applied in the direction of connecting components, pins, mechanical equipment, etc., can solve the problems of long assembly and disassembly time, large number of tools, inconvenient storage, etc., and achieve simple and easy technical solutions, simple structural processing, The effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

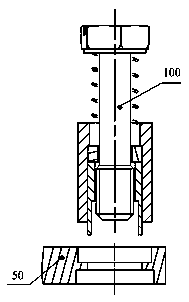

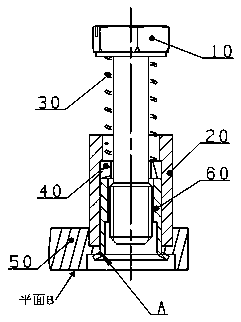

[0028] like figure 2 As shown, the present invention provides a captive fastening assembly, including a captive bolt 100 and a connecting structure 50; specifically, as image 3 As shown, the captive bolt includes an outer sleeve 20, a lock sleeve 60, a spring 30, a half ring 40 and a bolt 10 on the same axis; the outer sleeve 20 and the lock sleeve 60 are cylindrical, and the outer sleeve 20 and the lock sleeve 60 are cylindrical. The inner cavity is divided into two sections, which are respectively the inner cavity of the first outer sleeve and the inner cavity of the second outer sleeve. The inner diameter of the inner cavity of the first outer sleeve is smaller than the inner diameter of the inner cavity of the second outer sleeve; the inner ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com