Permanent magnet high pressure nitrogen spring

A high-pressure nitrogen and permanent magnet technology, applied in the direction of magnetic springs, springs, springs/shock absorbers, etc., can solve the problem that system pressure alarms and system pressure compensation cannot be realized, ordinary mold nitrogen springs cannot meet the requirements, and cannot provide constant pressure Air source gas and other issues, to achieve the effect of promoting high-pressure gas control technology, simplifying mold design, and improving economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

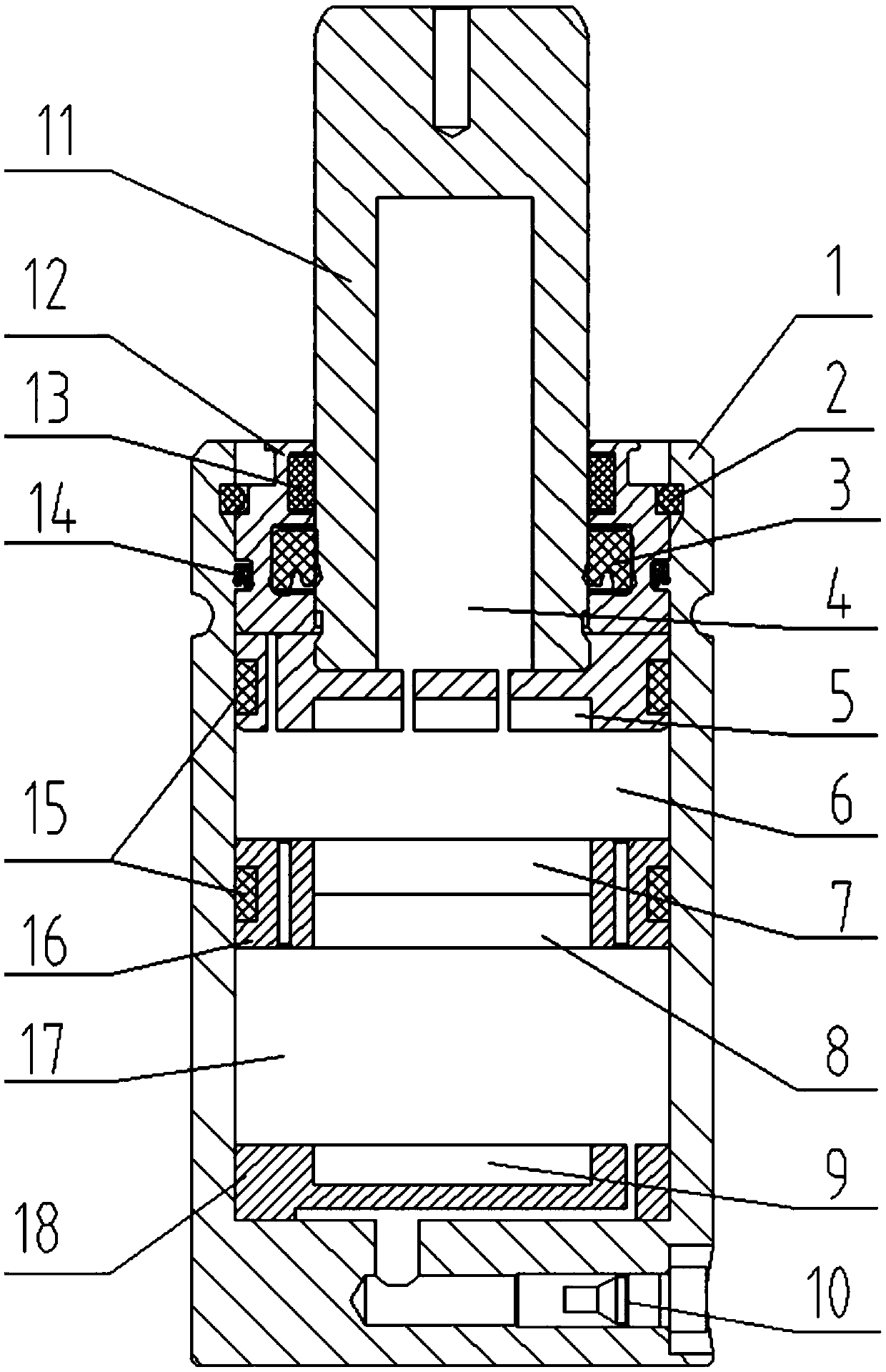

[0022] Such as figure 1 As shown, the permanent magnet high-pressure nitrogen gas spring includes cylinder body 1, permanent magnet A5, permanent magnet B7, permanent magnet C8, permanent magnet D9, charging valve 10, rod piston 11, upper end cover 12, rodless moving piston 16 and lower end Cover 18; the top of the cavity of the cylinder body 1 is equipped with an upper end cover 12 through the circlip 2, and is sealed by an O-ring 14; the rod piston 11 includes a piston rod and a piston body; a cavity A4 is opened in the piston rod, and the top of the piston rod There is a hoisting hole, the piston rod and the upper end cover 12 are slidably matched and sealed by the lip ring 3, and a dust-proof ring 13 is arranged between the piston rod and the upper end cover 12, and the dust-proof ring 13 is located above the lip ring 3; The body is slidingly fitted with the cavity of the cylinder body 1, a guide belt 15 is provided between the piston body and the cavity of the cylinder bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com