Although this technology is widely used, its shortcomings are obvious, mainly in: 1) In the rainstorm and

flood season, the

water level upstream of the gate is relatively high, and various floating objects such as branches, roots, and weeds gather on the upstream edge of the gate. Under the action of the gate, it often turns over the gate and directly hits the steel

wire rope of the sensor below, causing the wire

rope to be broken and causing the opening measurement to fail. Suspension on the wire rope will cause additional disturbance to the wire rope, which will cause a huge deviation in the opening measurement; 2) The wire rope will be wound on the hub in an orderly manner during the retraction process, and sometimes overlapping will occur, which will cause large measurement deviation

3) The scroll spring inside the sensor may

rust or fail mechanically after a long time, which will cause the wire rope not to be well tightened or retracted normally, or even broken by the cylinder piston

4) Since the sensor is installed outdoors, if the waterproof is not done well, in heavy rain weather, rainwater can easily enter the

encoder through the shaft of the

encoder in the sensor and cause the

encoder to be damaged

5) The displacement of the piston and the opening of the gate are not a simple

mathematical relationship, but a relatively complex

functional relationship. The calculation of this function involves many mechanical dimensions and installation position data of the gate itself. In actual field application, especially for later equipment These data are often difficult to obtain accurately, which brings many difficulties to the calculation of the arc door opening. In order to overcome this problem, in practical applications, the method of multi-point sampling

linear approximation of the opening is mostly used to fit the actual opening. The function curve calculates the opening, but this will not only cause a large

calculation error, but also the debugging and calibration is very troublesome. Generally, at least 10 opening points need to be sampled, and each sampling point needs to use other methods to measure the actual opening. As the basic data for opening calibration, it is also necessary to ensure a certain measurement accuracy

Although this solution does not have some of the disadvantages of the above-mentioned rope-type displacement sensor, it also has its own disadvantages: 1) Since the displacement sensor is built-in, this requires the displacement sensor to be installed inside the cylinder before the cylinder leaves the factory. Once the displacement sensor fails, it will be extremely difficult to repair or replace. Sometimes it is even necessary to remove the entire cylinder and return it to the factory for repair, and the repair period is long and expensive.

2) The displacement of the piston and the opening of the gate are not a simple

mathematical relationship, but a relatively complex

functional relationship. The calculation of this function involves many mechanical dimensions and installation position data of the gate itself. In actual field applications, especially for later equipment These data are often difficult to obtain accurately, which brings many difficulties to the calculation of the arc door opening. In order to overcome this problem, in practical applications, the method of multi-point sampling

linear approximation of the opening is mostly used to fit the actual opening. The function curve calculates the opening, but this will not only cause a large

calculation error, but also the debugging and calibration is very troublesome. Generally, at least 10 opening points need to be sampled, and each sampling point needs to use other methods to measure the actual opening. As the basic data for opening calibration, it is also necessary to ensure a certain measurement accuracy

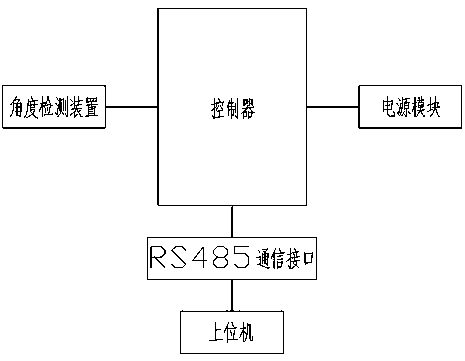

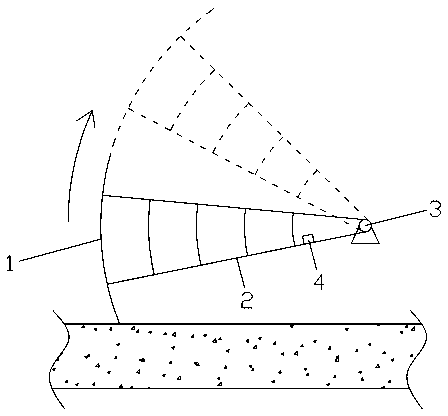

[0005] 3. For the opening measurement of the hoisting arc gate, the common solution is to install an absolute encoder concentrically with the end face of the reel, and measure the

angular displacement and

angular displacement signal of the reel through the absolute encoder. Generally through RS422 interface (SSI protocol), RS485 interface (

Modbus,

Profibus and other protocols), 4-20mA

current loop, etc. to transmit to the PLC or opening detection instrument in the corresponding arc door

electrical control cabinet, the

angular displacement of the drum is transformed through linear transformation Calculate the

linear displacement of the hoisting steel wire rope, and then convert the

linear displacement of the steel wire rope to the gate opening. Since the

linear displacement of the steel wire rope and the gate opening are also not a simple

mathematical relationship, it is a relatively complicated

functional relationship. The calculation of this function involves The mechanical dimensions and installation position data of many gates themselves are often difficult to obtain accurately in field practical applications, especially for the opening measurement devices equipped later, which brings many difficulties to the calculation of the arc gate opening. In order to overcome this The problem is that in practical applications, the method of multi-point sampling

linear approximation of the opening is usually used to fit the actual opening function curve to calculate the opening, but this will not only cause a large

calculation error, but also very troublesome to debug and calibrate. Generally, at least 10 samples are required. For more than three opening points, each sampling point needs to use other methods to measure the actual opening once, as the basic data for opening calibration also needs to ensure a certain measurement accuracy

Login to View More

Login to View More  Login to View More

Login to View More