Vertical prestressed steel bar detection module and detection method for bridge concrete construction

A technology of vertical prestressing and detection module, applied in the direction of measuring force, measuring device, instrument, etc., can solve bridge deck cracks or cracks, vertical prestressing steel bar does not have a good method and equipment, construction quality and construction Safety can not be effectively guaranteed and other problems, to achieve the effect of construction quality and construction safety guarantee, low production cost, and easy construction operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

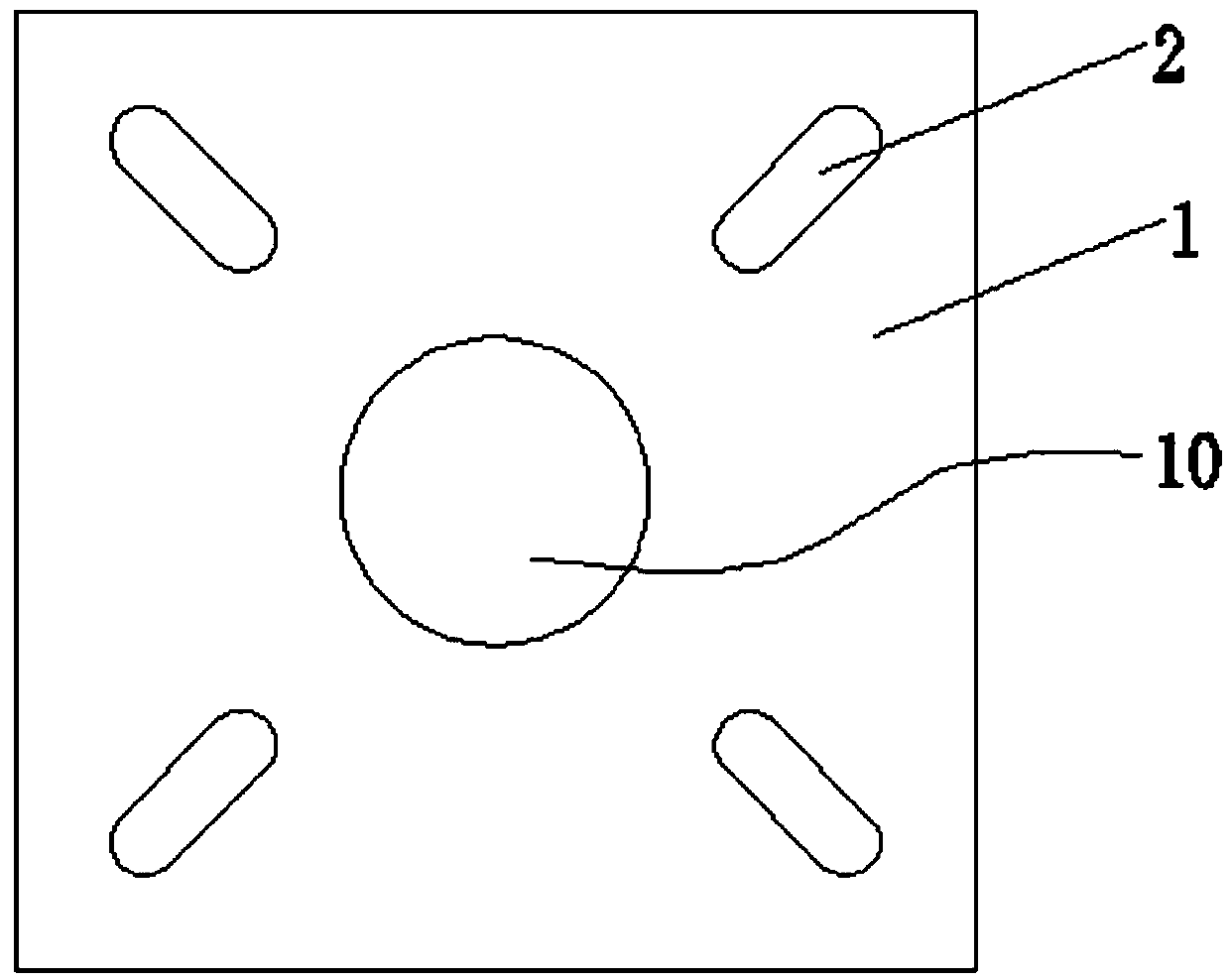

[0022] Such as figure 1 As shown, the vertical prestressed steel bar detection module for bridge concrete construction according to the present invention includes a substrate 1 and a strain gauge 2, the strain gauge 2 is attached to the substrate 1, and the strain gauge 2 and the substrate 1 are relatively fixedly installed. The substrate 1 is provided with a through hole 10 . When the substrate 1 is deformed by force, the strain gauges 2 attached to the substrate 1 will also deform correspondingly.

[0023] In the present invention, the number of strain gages 2 attached to the substrate is one or more, and multiple strain gages 2 are attached to allow multi-point testing, thereby improving the accuracy of detection.

[0024] The strain gauge 2 of the present invention is pasted on the front or back of the substrate 1 .

[0025] The strain gauge 2 of the present invention is attached to the side surface of the substrate 1 .

[0026] The strain gage 2 of the present inventio...

Embodiment 2

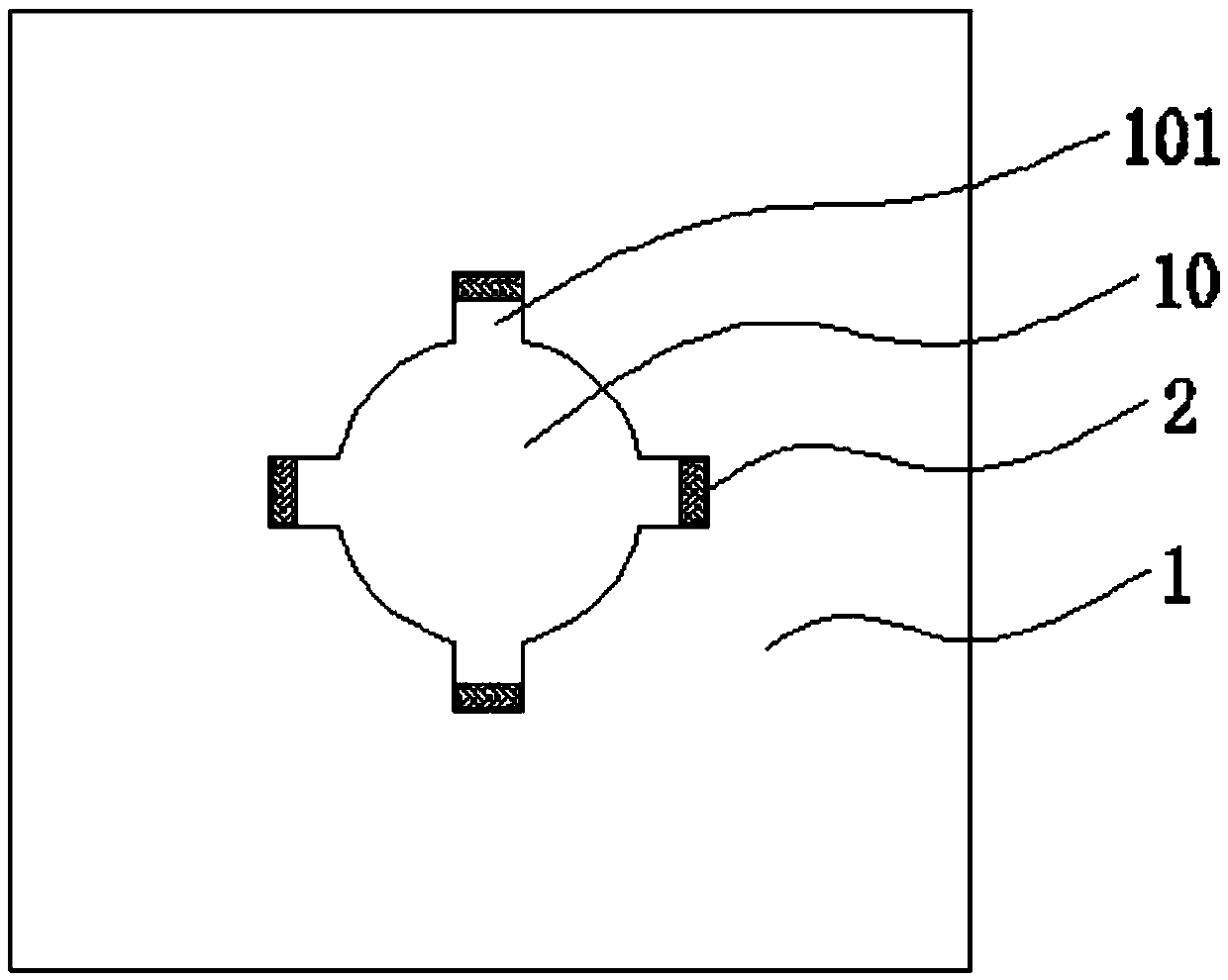

[0029] Such as figure 2 As shown, the vertical prestressed steel bar detection module for bridge concrete construction according to the present invention includes a substrate 1 and a strain gauge 2, the strain gauge 2 is attached to the substrate 1, and the strain gauge 2 and the substrate 1 are relatively fixedly installed. The substrate 1 is provided with a through hole 10 . When the substrate 1 is deformed by force, the strain gauges 2 attached to the substrate 1 will also deform correspondingly.

[0030] The side wall of the opening 10 of the present invention is provided with a groove 101 , and the strain gauge 2 is attached and fixed in the groove 101 . The strain gauge 2 is arranged in the recessed groove 101 , the groove 101 is a harbor for accommodating the strain gauge 2 , and the strain gauge 2 can be effectively protected to avoid damage to the strain gauge 2 , thus affecting the test result.

[0031] The side wall of the opening 10 of the present invention is p...

Embodiment 3

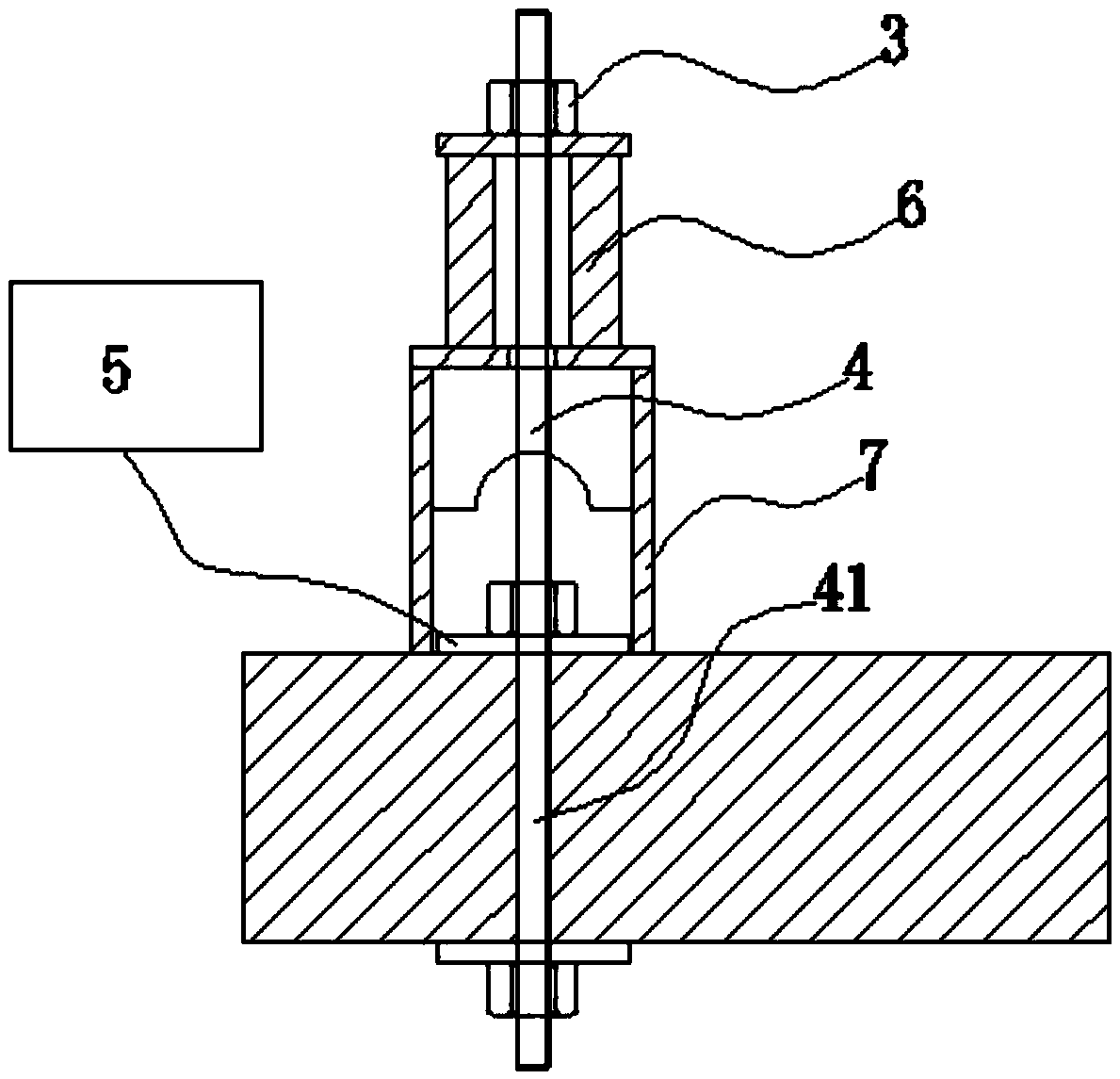

[0033] Such as image 3 and Figure 4 As shown, the vertical prestressed steel bar detection method of bridge concrete construction, the steps are as follows: it includes a nut 3, a steel bar 4 and a strain tester 5, and the vertical prestressed steel bar detection module of the bridge concrete construction includes a substrate 1 and a strain gauge 2. The strain gauge 2 is pasted on the substrate 1, and the strain gauge 2 and the substrate 1 are relatively fixedly installed. The substrate 1 is provided with a through hole 10, and one end of the steel bar 4 penetrates through the hole 10 and is connected to the substrate 1. The nut 3 is threaded, the other end of the steel bar 4 is relatively fixed, the strain gauge 5 is connected to the strain gauge 2 to collect the data of the strain gauge 2, and the strain gauge 5 judges whether the tensile force of the reinforced section 41 is based on the data collected from the strain gauge 2 Meet the set requirements. The strain tester...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com