Tire burst simulation rim and tire burst simulation method

A technology of puncture simulation and rim, which is applied in the field of puncture simulation and can solve the problems of large volume, complex structure, and car crashes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

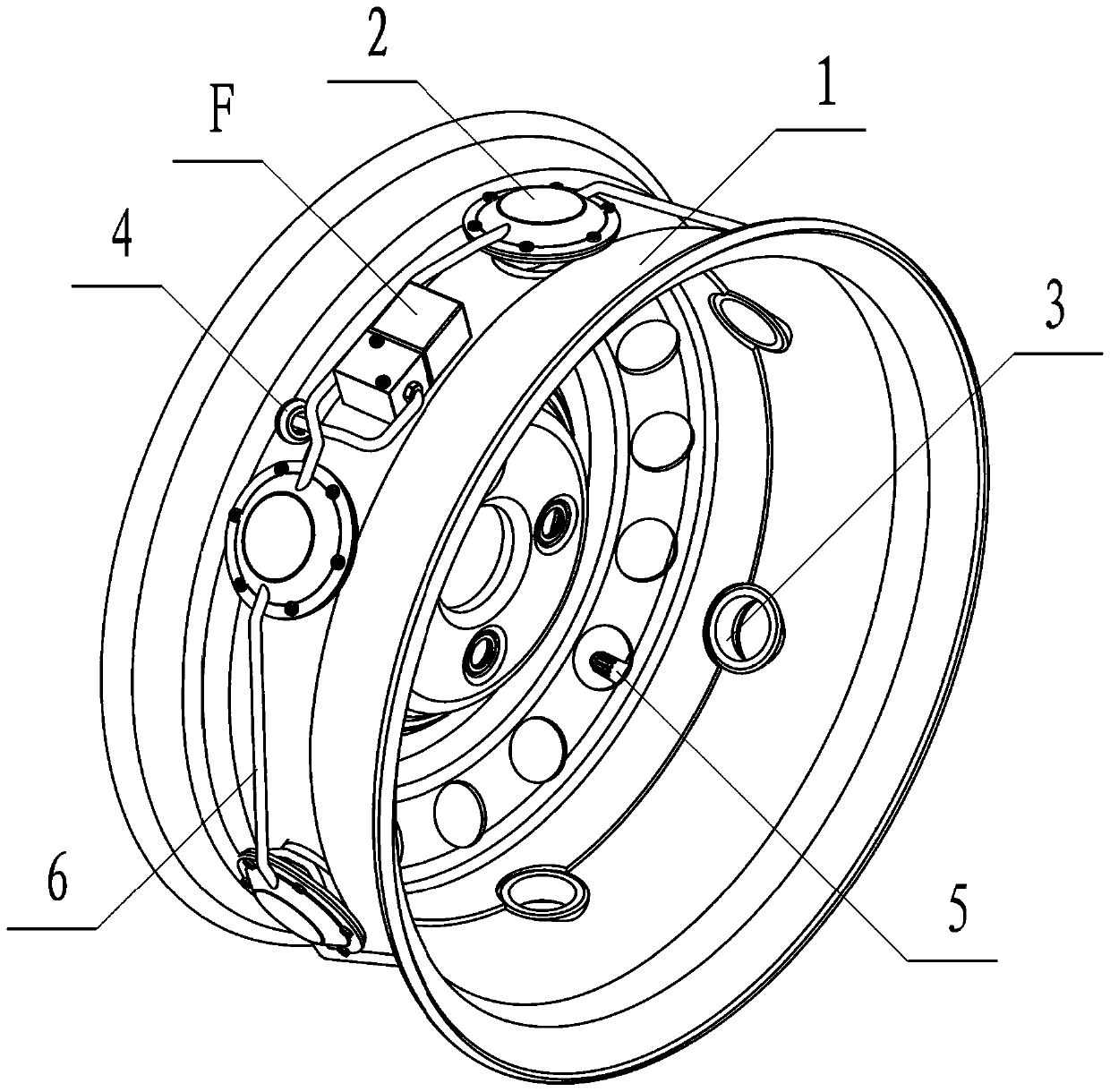

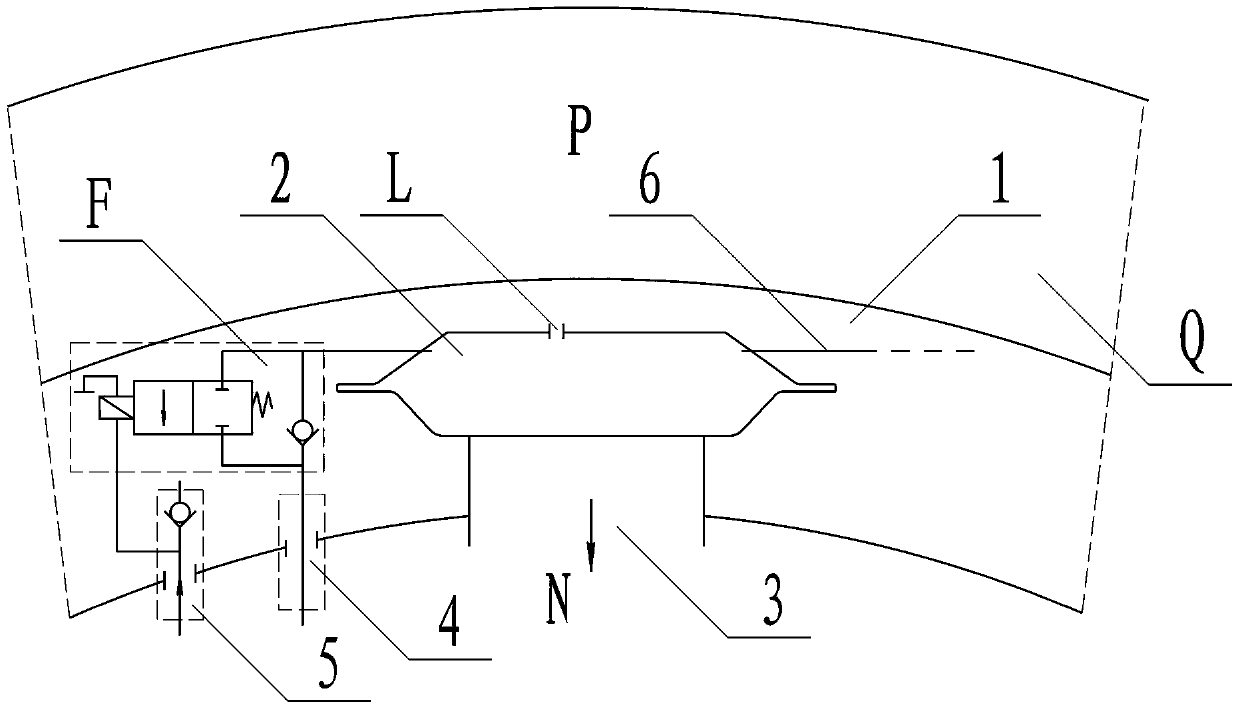

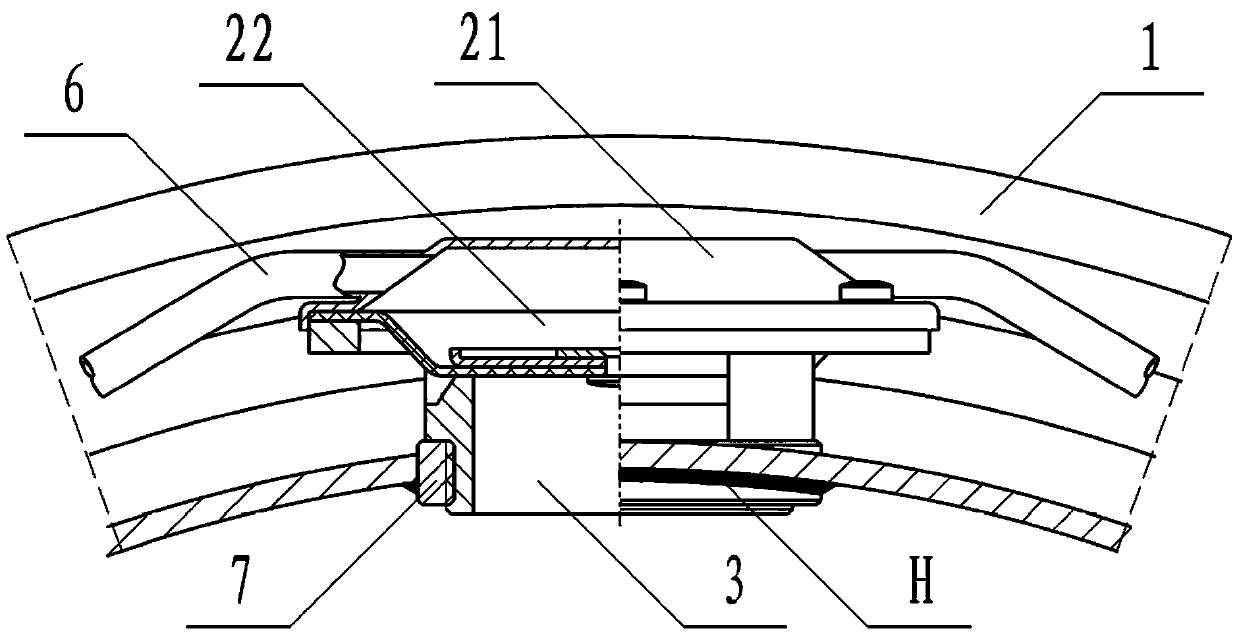

[0027] Combine below figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , and describe Embodiment 1 of the present invention in detail.

[0028] Such as figure 1 As shown, the tire burst simulation rim of the present invention is characterized in that: the tire burst simulation rim is composed of rim (1), deflation actuator (2), main valve seat (3), reset valve (4), inflation gas nozzle (5), pilot line (6), threaded sleeve (7) and electromagnetic pilot valve (F); at the rim groove of the rim (1), there are fasteners and BMCS sensor module installed Several through-holes for installing the main valve seat threaded bushing (7) (see image 3 ), the threaded sleeve (7) is welded (H) to the rim (1) for sealing; the circumferential direction of the rim (1) is provided with a through hole for installing the reset gas nozzle (4) and the inflation gas nozzle (5); The air-controlled main valve is composed of the deflation actuator (2) and the main valve seat (3). The main va...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com