Fault Diagnosis Method for a Class of Rotating Machinery System Based on Adaptive Noise Reduction Algorithm

A technology for rotating machinery and system failures, applied in the testing of machines/structural components, instruments, measuring devices, etc., which can solve problems such as inability to achieve accurate prediction results and inability to ensure the collection of vibration signals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] A fault diagnosis method for a rotating machinery system based on an adaptive noise reduction algorithm, including the following steps:

[0032] Step 1: Obtain system vibration signal;

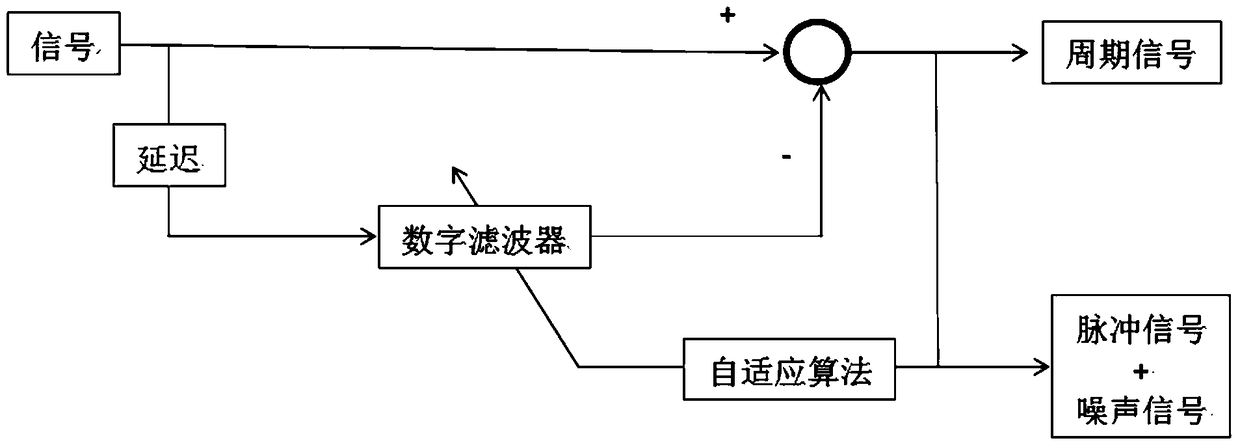

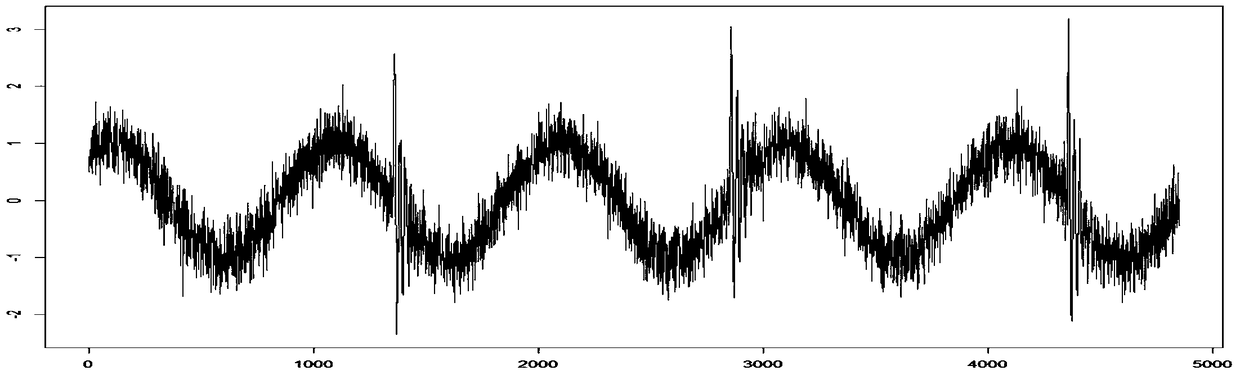

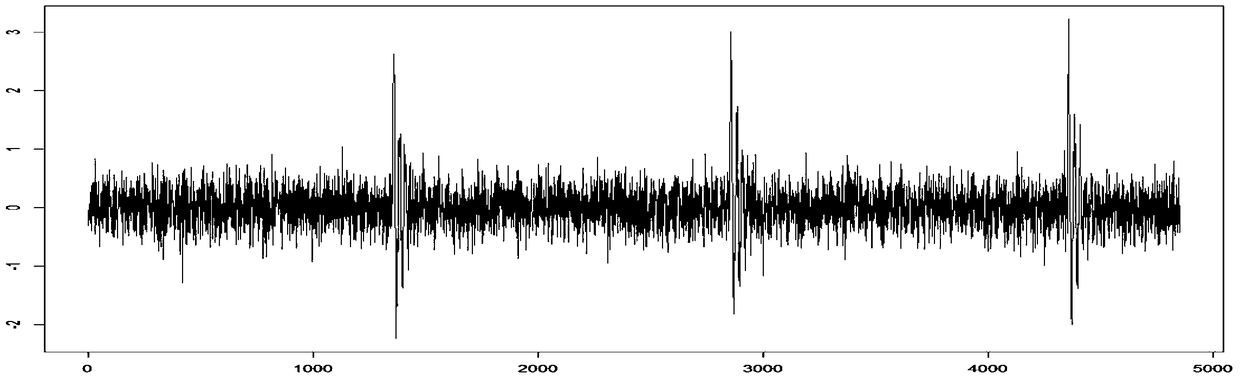

[0033] Step 2: The vibration signal is divided into two parts by an adaptive filtering algorithm, the first part is a periodic signal, and the second part is a pulse signal plus noise signal; figure 1 As shown, the body is to directly input the system vibration signal into the superposition calculator, and then pass the system vibration signal through a digital filter after a delay. The delay is 0.3 times the length of one period of the period signal. After being processed by the digital filter, One part is superimposed by the superposition calculator and the previous signal, and finally the periodic signal is calculated from the superposition calculator; the other part is separated by an adaptive algorithm to separate the pulse signal and the noise signal;

[0034] Step 3: For the sec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com