Automatic vending machine for freshly-made food and working method thereof

The technology of a vending machine and working method is applied in the direction of coin-operated equipment for distributing discrete items, coin-operated equipment for distributing discrete items, coin-operated equipment for distributing discrete items, etc., which can solve the problem that is difficult to ensure Food freshness, food and beverages cannot be prepared on-site or cooked on-site, and cannot meet people's purchase needs, etc., to achieve the effect of freshness satisfaction and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Example of a ready-made food vending machine:

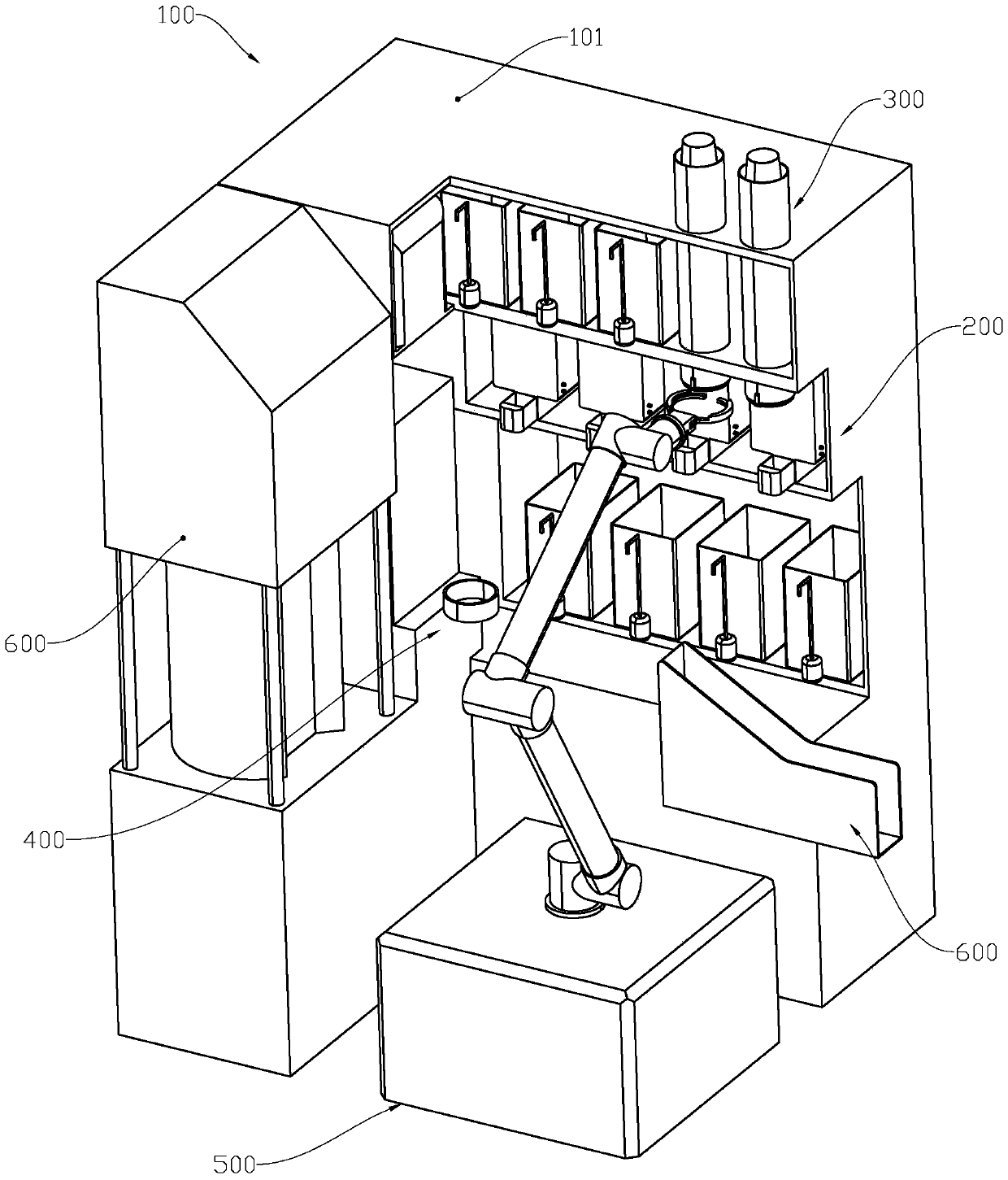

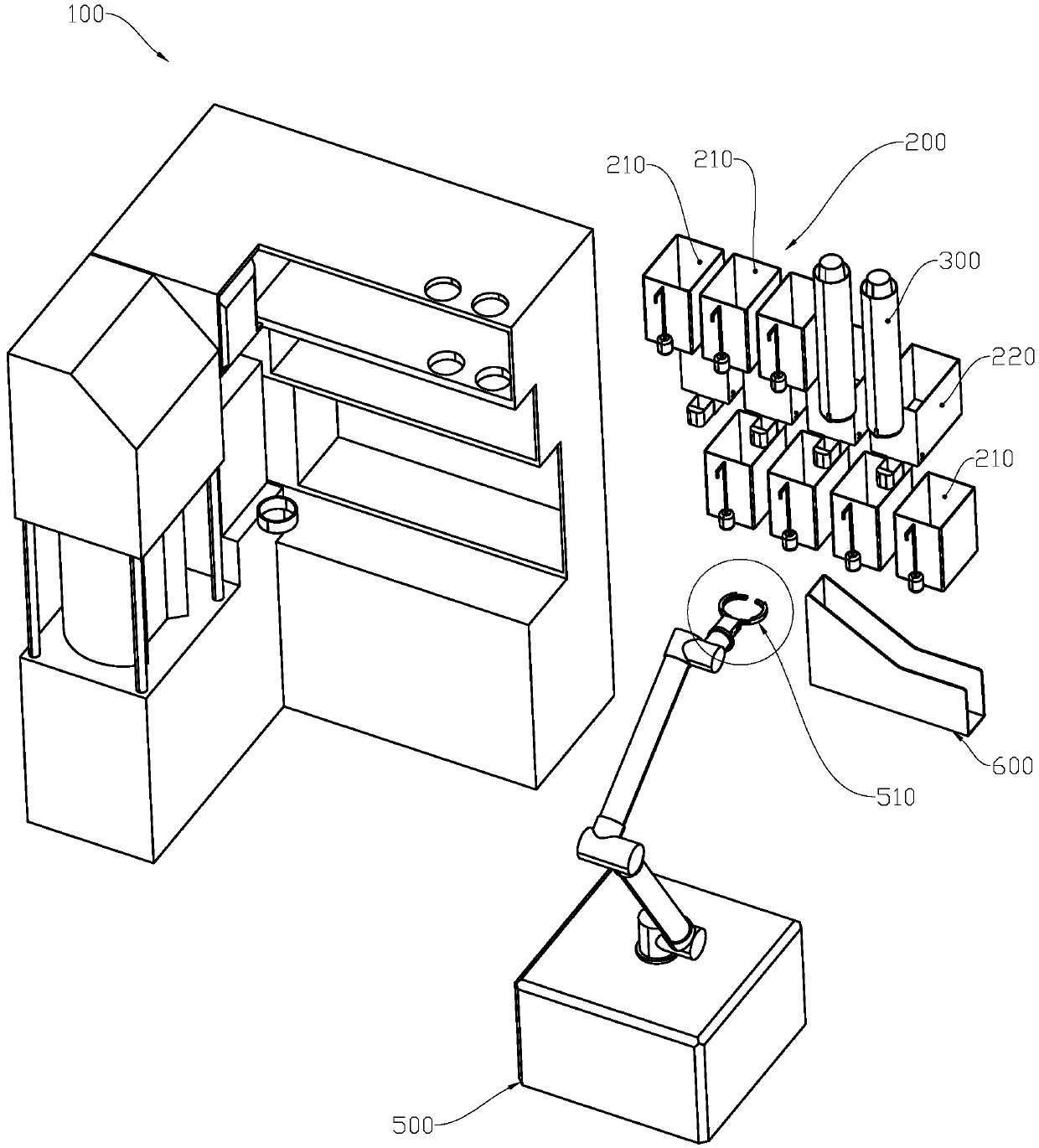

[0034] The ready-to-eat food vending machine of the present invention includes a part outside the body and a part inside the body. Such as figure 1 as shown, figure 1 It is a structural diagram of the part 100 inside the body of a ready-made food vending machine. The body includes a main cabinet 101, and the main cabinet 101 is provided with a plurality of storage positions for placing a plurality of storage units 200, a plurality of container storage units 300, sealing Unit 400 and ice machine 600. The storage unit 200 and the container storage unit 300 are located on the first part of the main cabinet 101 , and the sealing unit 400 and the ice maker 600 are located on the second part of the main cabinet 101 .

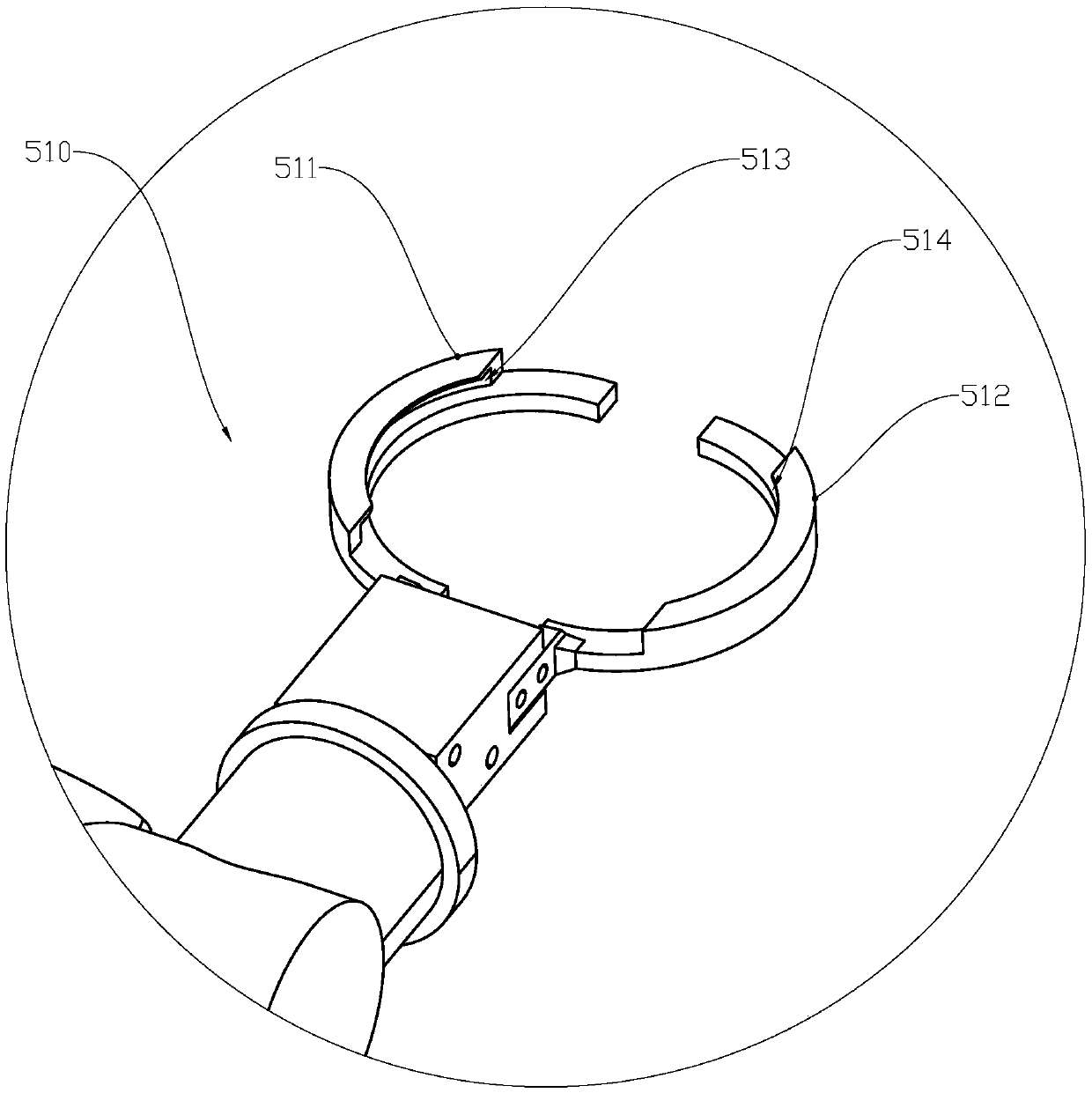

[0035] The part 100 inside the body of the ready-to-eat food vending machine is also provided with a multi-axis robot arm 500, and the multi-axis robot arm 500 is arranged at the intersection of the first part ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com