A permanent magnet coupling control method and a permanent magnet governor

A technology of permanent magnetic coupling and governor, applied in the direction of electromechanical transmission, electromechanical devices, electrical components, etc., can solve the current situation that the hard connection between the motor and the load cannot be changed, the impact of the life of the transmission system cannot be removed, and the adaptation to changes in the surrounding environment Poor capacity and other problems, to achieve the effect of low maintenance cost, long service life, and eliminate the impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be described in more detail below in conjunction with the description figures and embodiments.

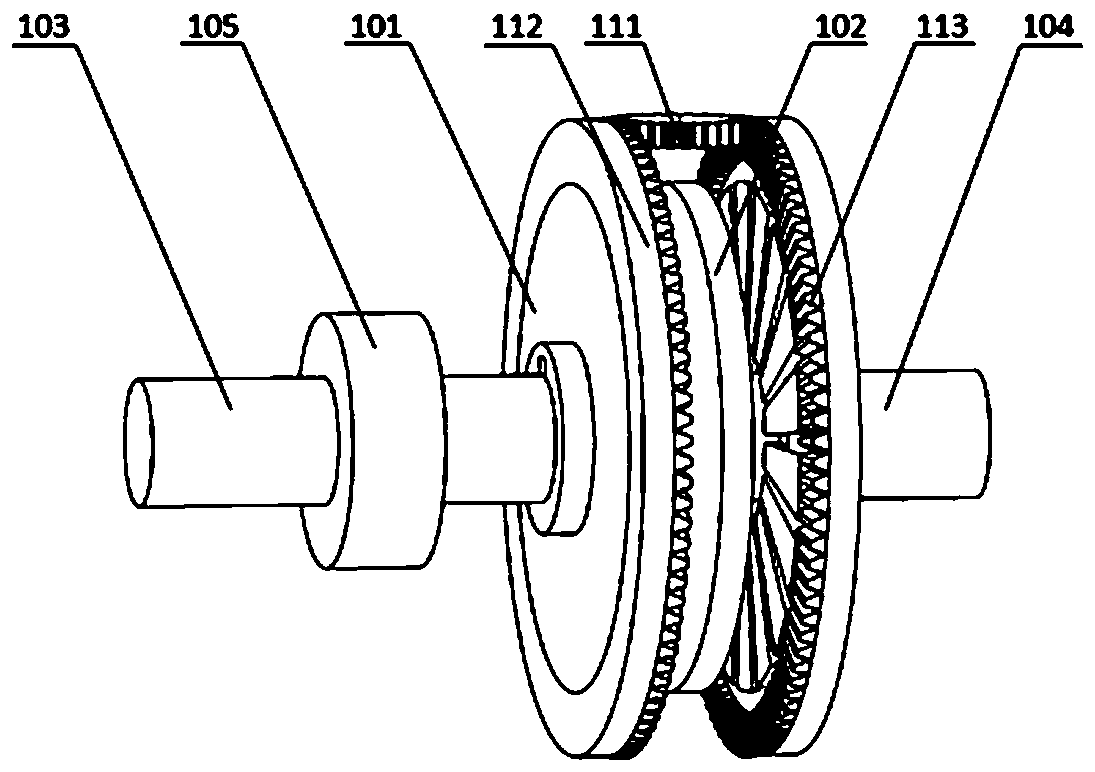

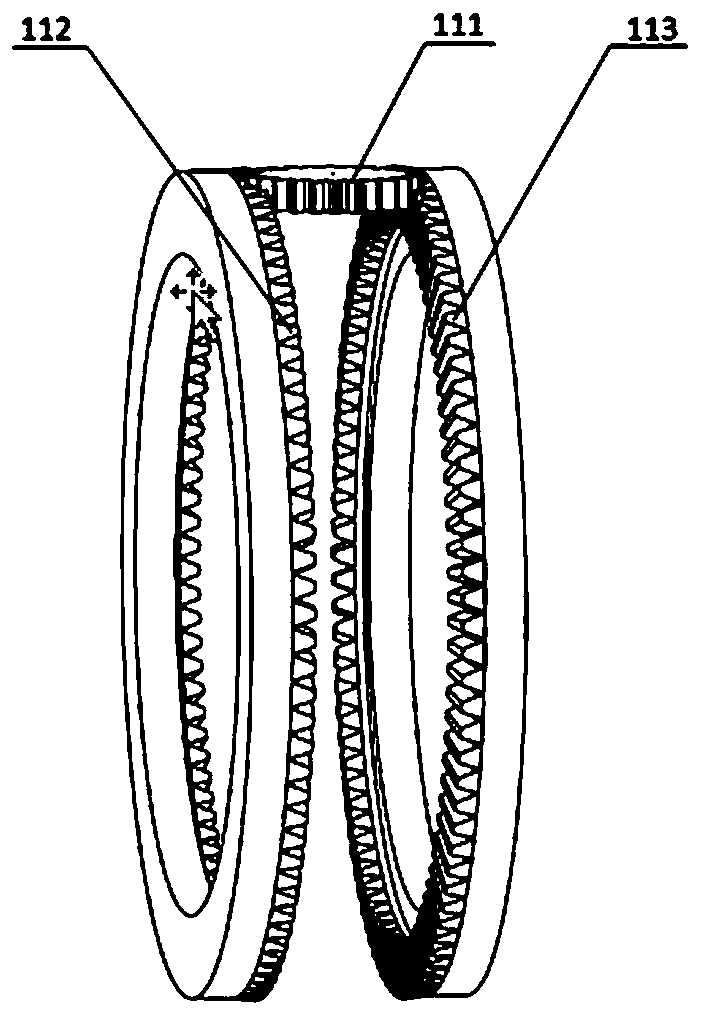

[0044] Such as Picture 1-1As shown, an embodiment of the present invention, a disc-shaped permanent magnet coupling speed governor is composed of a permanent magnet rotor 101 and a conductor rotor that is a conductor disc 102. The external connection end of the conductor disc 102 is connected to the motor shaft 104 connection, the external connection end of the permanent magnet rotor 101 is connected to the load shaft 103, the controller 105 of the manipulation mechanism is assembled between the permanent magnet rotor 101 and the load shaft 103, and the manipulation mechanism controller 105 is used for Adjust the central control gear 112, gear 113 and gear 114, adjust the relative circumferential position angle of the permanent magnet poles on both sides of the permanent magnet rotor 101, change the coupling strength of the conductor disk 102 cutti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com