Rotating valve rotational speed control method for measuring-while-drilling tool

A technology of speed control and measurement while drilling, applied in construction and other directions, can solve problems such as unreported, unsatisfactory, and unconsidered, and achieve the effect of friendly application environment, reliable control route, and scientific control principle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

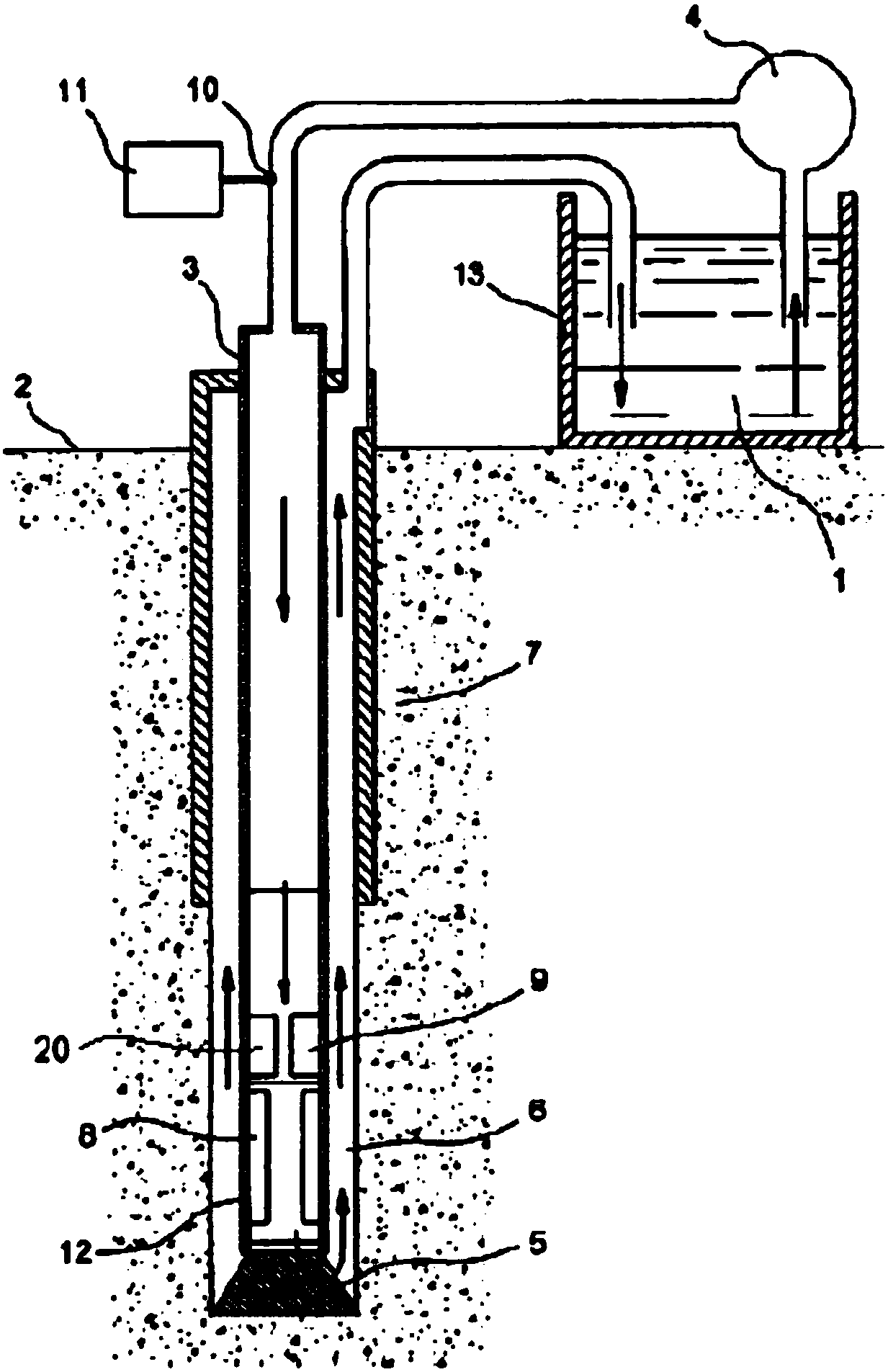

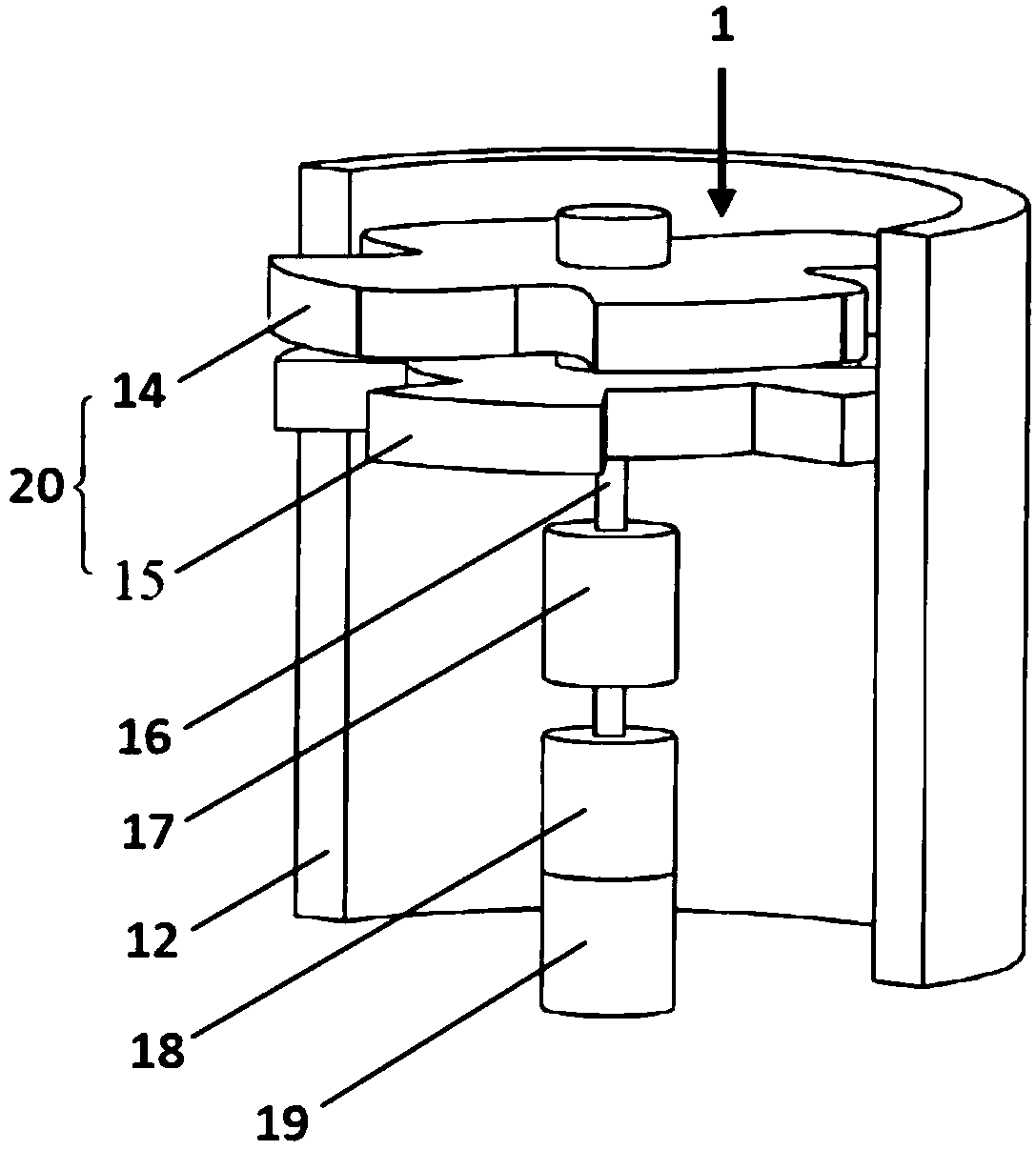

[0019] The rotational speed control method of the rotary valve involved in this embodiment is used to control the rotational speed of the rotary valve rotor in the drilling fluid continuous pressure wave signal generator in the measurement-while-drilling tool in the drilling device, and realizes the control process in the drilling device with the rotary valve installed, The main structure of its drilling equipment includes drilling fluid 1, ground surface 2, drill string 3, drilling fluid pump 4, drill bit 5, annular space 6, formation 7, drilling parameter and formation parameter measurement device 8, drilling fluid continuous pressure wave signal generator 9. Pressure sensor 10, signal processing device 11, drill collar 12 and drilling fluid tank 13; wherein the drilling fluid continuous pressure wave signal generator 9 includes a rotary valve stator 14, a rotary valve rotor 15, a rotor shaft 16, a speed reducer 17, Motor 18, motor control circuit 19 and rotary valve 20; firs...

Embodiment 2

[0023] This embodiment is based on the following calculations and analysis to realize the control of the rotational speed of the rotary valve:

[0024] (1) Realize the linearization correction of the rotary valve speed control system based on feedforward compensation According to the derivative relationship between the speed and the rotation angle, there is If the rotation angle of the rotary valve is controllable, its speed is controllable;

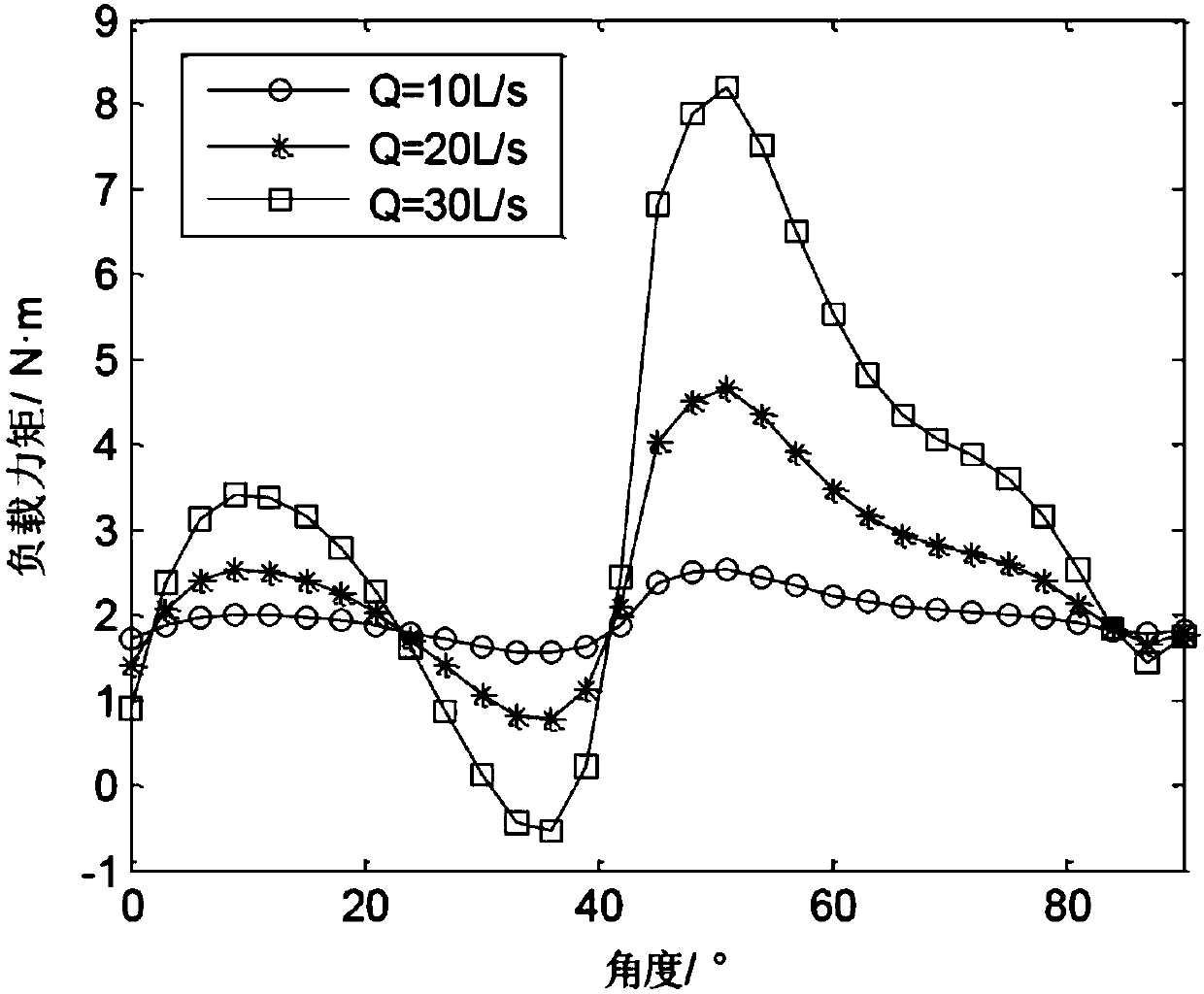

[0025] Load moment M L (θ) is non-monotonic and severely nonlinear with the rotation angle, see the attached image 3 , if the M L The mathematical model of (θ) is expressed in polynomial form

[0026] m mod (θ)=a+ρQ 2 (b 0 +b 1 θ+b 3 θ 2 +Λ+b m θ m ) (1)

[0027] Among them, θ is the rotation angle; Q is the drilling fluid flow rate; ρ is the drilling fluid density; a is a constant; b 0 —b m is the polynomial coefficient; m is the power of each item in the polynomial;

[0028] According to the torque balance equation of ...

Embodiment 3

[0084] In this embodiment, in the drilling device containing the rotary valve in embodiment 1 and based on the principle of embodiment 2, the technological process for realizing the speed control of the rotary valve is as follows:

[0085] First, the feed-forward compensation method is used to correct the nonlinearity of the rotary valve speed open-loop control system, and then the speed open-loop control system that has been linearized and corrected is formed into a PID closed-loop control through negative feedback of the speed, and then the PID parameters are reasonably determined to realize the rotation. Fast follow-up control of the valve speed; in the nonlinear correction process, the angle control item in the angle control mathematical model (2) of the rotary valve is set as a constant, and the motor control voltage expression under ideal conditions expressed by formula (6) is obtained formula, the load torque item in formula (6) is replaced by the mathematical model of r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com