Rotary feeding device of sinter cooling furnace

A technology of rotating feeding and feeding device, used in furnaces, furnace components, processing discharged materials, etc., can solve problems such as difficult sealing and difficult distribution, and achieve the effects of convenient replacement and maintenance, reducing wear and increasing effective volume.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

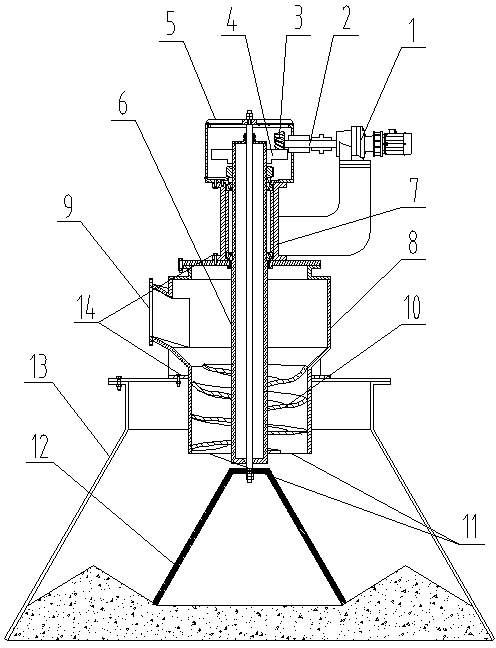

[0021] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0022] Such as figure 1 As shown, the sinter cooling furnace rotary feeding device includes a transmission device and a feeding device. The feeding device is located at the furnace mouth of the cooling furnace 13. The transmission device includes a motor 1, a rotating shaft 2, a driving gear 3, a passive Gear 4, transmission shaft 6, protective cover 5 and bracing frame 7, described feed device comprises feed cover 8, feed inlet 9, screw feeder 10, discharge outlet 11 and conical material bell 12; The motor 1 is connected with one end of the rotating shaft 2, and the other end of the rotating shaft 2 is connected with the driving gear 3, and the driving gear 3 meshes with the driven gear 4 around the transmission shaft 6, and the driving gear 3, the transmission shaft 6 and the driven gear 4 are provided with Protective cover 5, a su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com