Method and controls system for automatically adjusting efficiency of DC brushless motor according to loads

A brushless DC motor, automatic adjustment technology, applied in the direction of a single motor speed/torque control, current controller, sustainable manufacturing/processing, etc. The effect of improving time efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

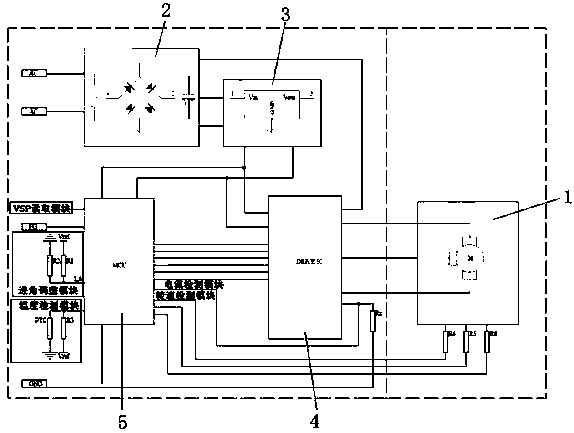

[0032] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific preferred embodiments.

[0033] Such as Figure 5 As shown, a method for automatically adjusting the efficiency of a brushless DC motor according to the load includes the following steps:

[0034] The first step is to input the target speed: input the required target speed in the motor input panel, and the VSP reading module will read the target speed.

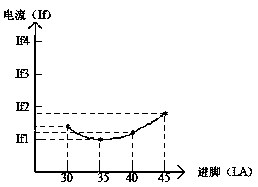

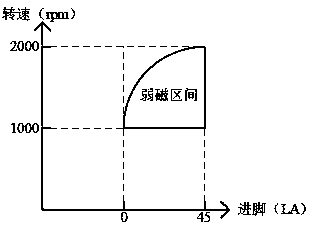

[0035] The second step is to match the actual speed of the motor with the target speed: the speed detection module detects the actual speed of the motor, and through the control of the speed loop, the actual speed of the motor reaches the target speed in the first step, and the current detection module samples The current value when the target speed is reached, and recorded as lf.

[0036] In this step, the actual speed of the motor is controlled through the speed loop. When the actual speed of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com