Frequency converter

A frequency converter and radiator technology, applied in the field of frequency converters, can solve the problems of hindering air flow, occupying the air duct space of the radiator, and increasing the cost, so as to achieve the effects of reducing cost, solving heat dissipation, and reducing volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to enable those of ordinary skill in the art to more clearly understand the purpose, technical solutions and advantages of the invention, the invention will be further described below with reference to the accompanying drawings and embodiments.

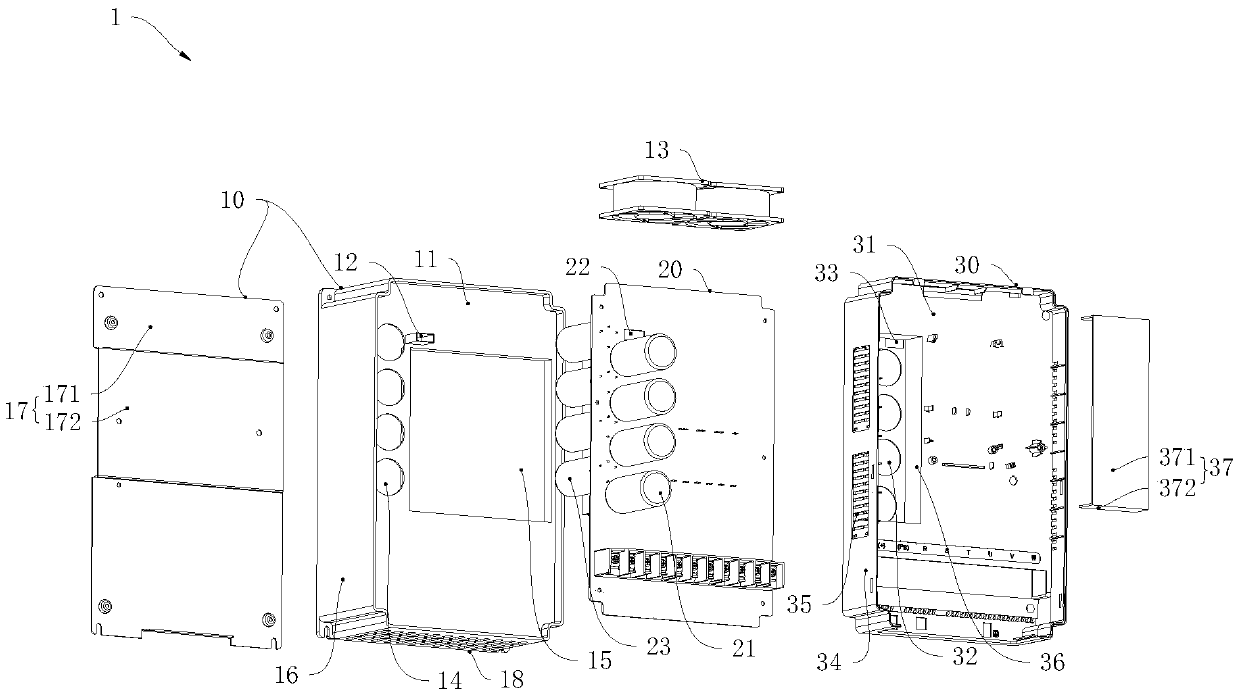

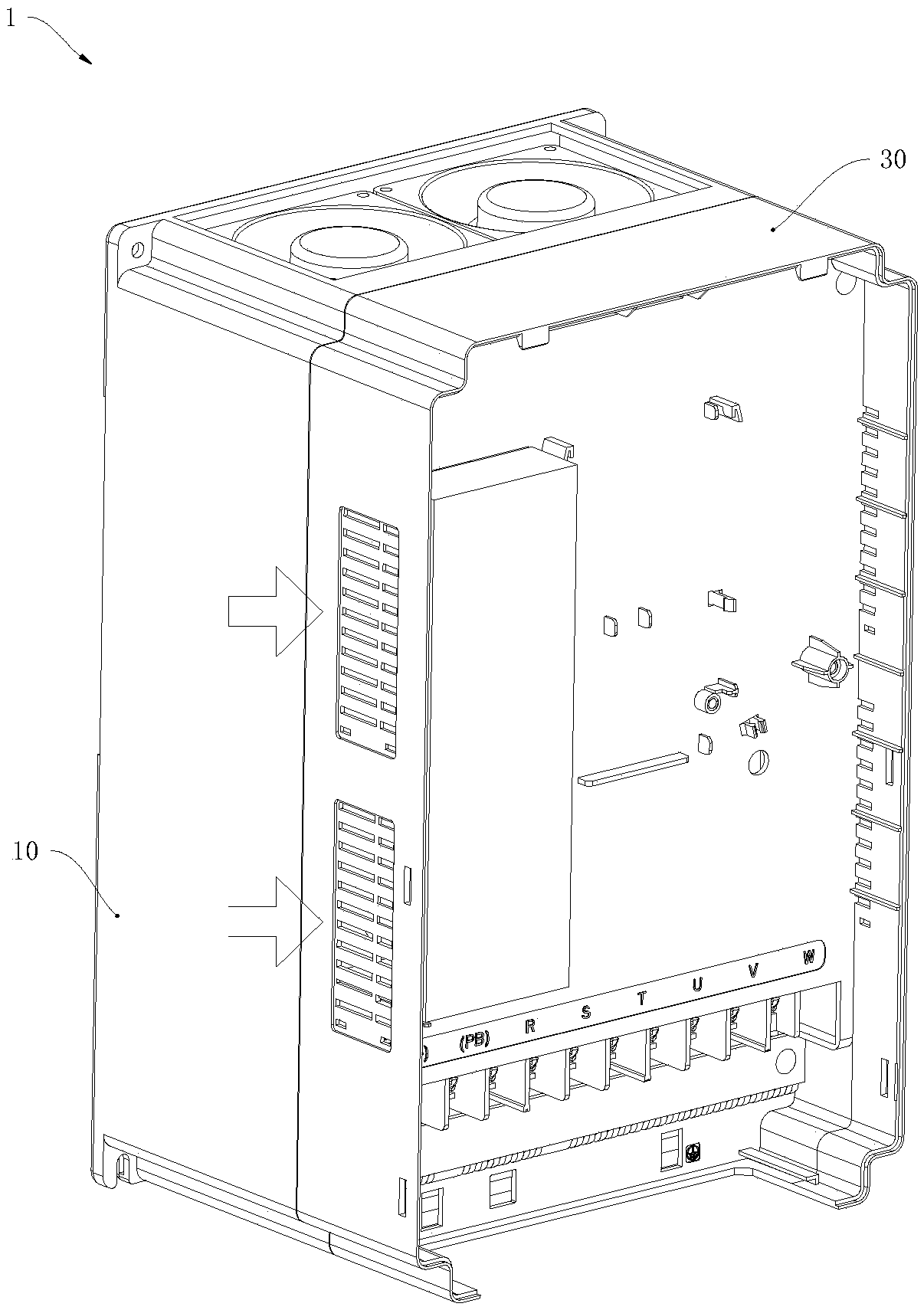

[0018] Reference Figure 1 to Figure 2 Shown are an exploded view and an assembly view of a frequency converter in a preferred embodiment. In this embodiment, the frequency converter 1 includes a first box body 10, a second box body 30 covering the first box body 10, and a first top plate 11 and a second box body 30 arranged on the first box body 10. In the driving board 20 between the second bottom plates 31, a number of first electrolytic capacitors 21 are provided on the side of the driving board 20 close to the second box 30, and a second ventilation hole 22 is provided near the first electrolytic capacitor 21, The second bottom plate 31 is provided with a first through hole 32 through which the first electrolytic ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com