Demountable silo

A silo and base technology, applied in the field of building detachable silos, can solve the problems of expensive maintenance, expensive manufacturing of metal silos, and difficulty in transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

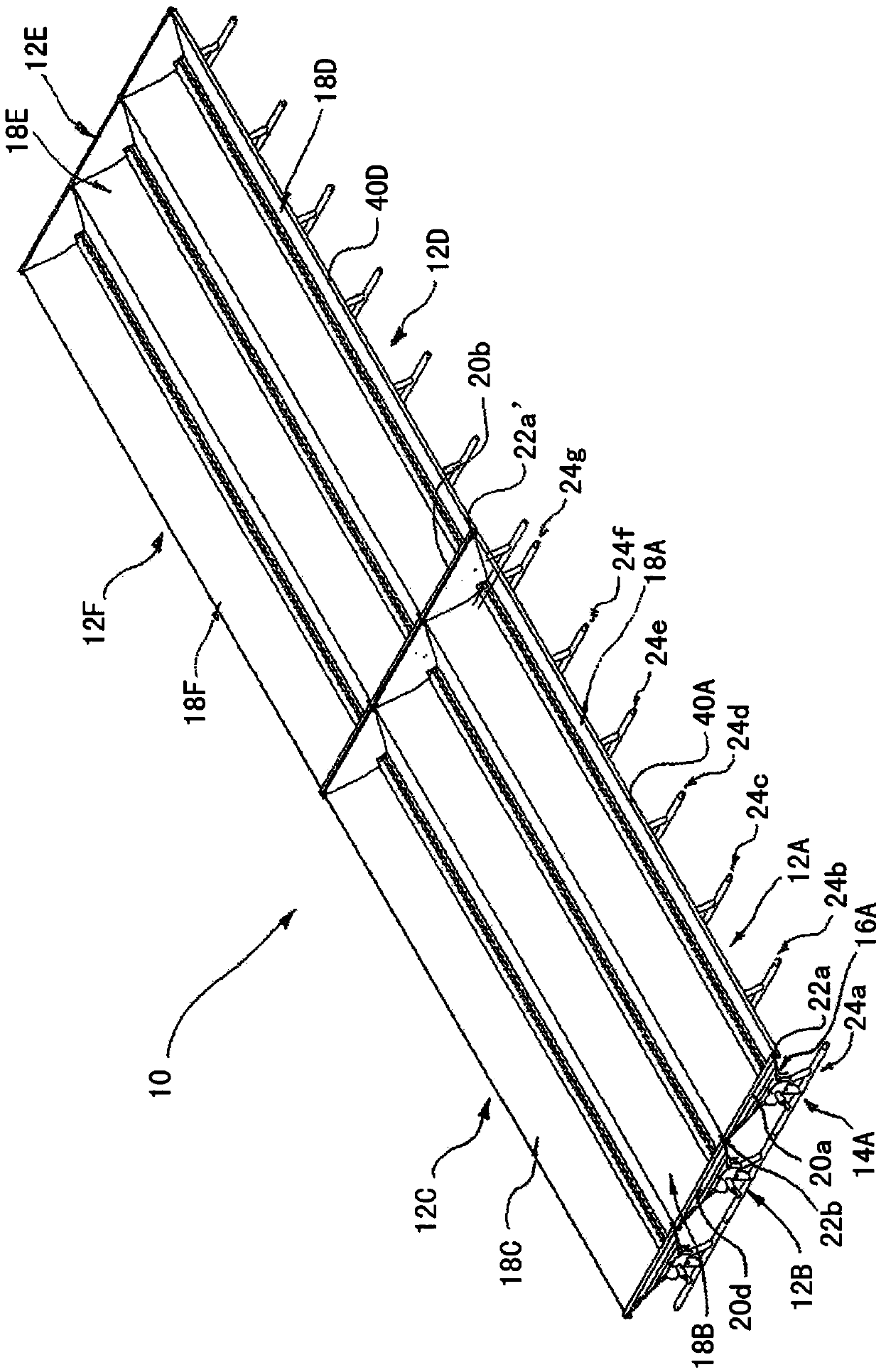

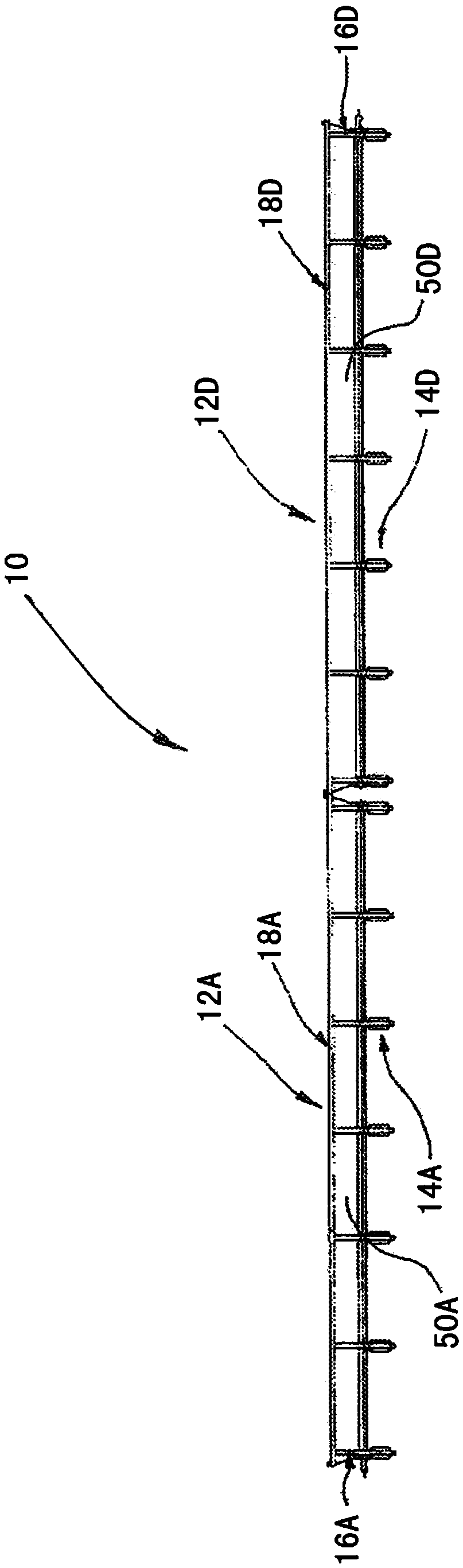

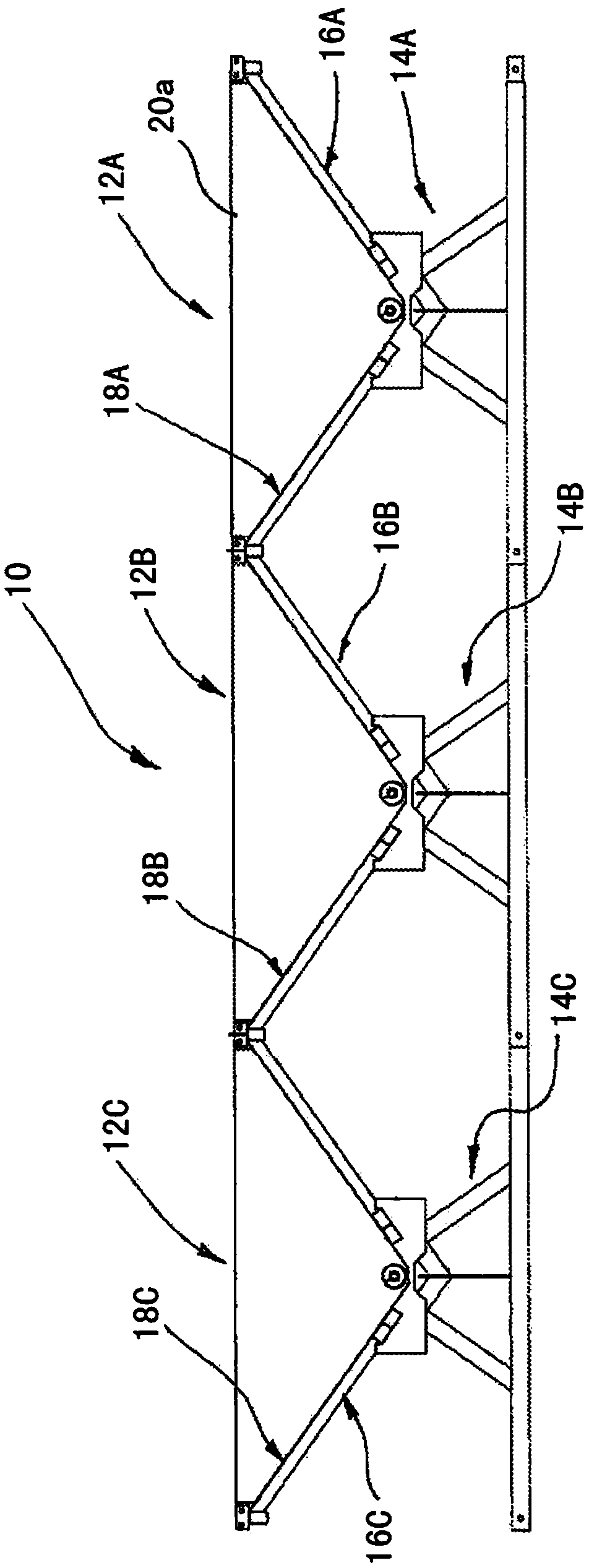

[0040] like Figures 1 to 3 As shown, according to the preferred embodiment of the present invention, the collapsible silo 10 is constructed from a series of interconnected silo modules 12A to 12F. The silo modules, such as 12A, are each of substantially identical construction and are interconnected side-by-side and end-to-end. The collapsible silos 10 of this example are arranged in three (3) rows and two (2) columns of silo modules 12A to 12F. The collapsible silo 10 is designed to contain granules, including granulated products, and is constructed according to the characteristics of the granules and their storage requirements. The provision of multiple silo modules, such as 12A to 12F, together contain significantly more piles of particulate matter than a single silo module. The maximum storage capacity of the collapsible silo 10 is largely determined by the angle of repose of the piled granular product. This system utilizes multiple modules such as 12A to 12F, thereby e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com