Heat treatment jig

A fixture and mounting surface technology, applied in lighting and heating equipment, furnaces, capacitors, etc., can solve the problems of uniform exposure to ambient gas, difficult placement of ceramic molded objects, and quality heating deviations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

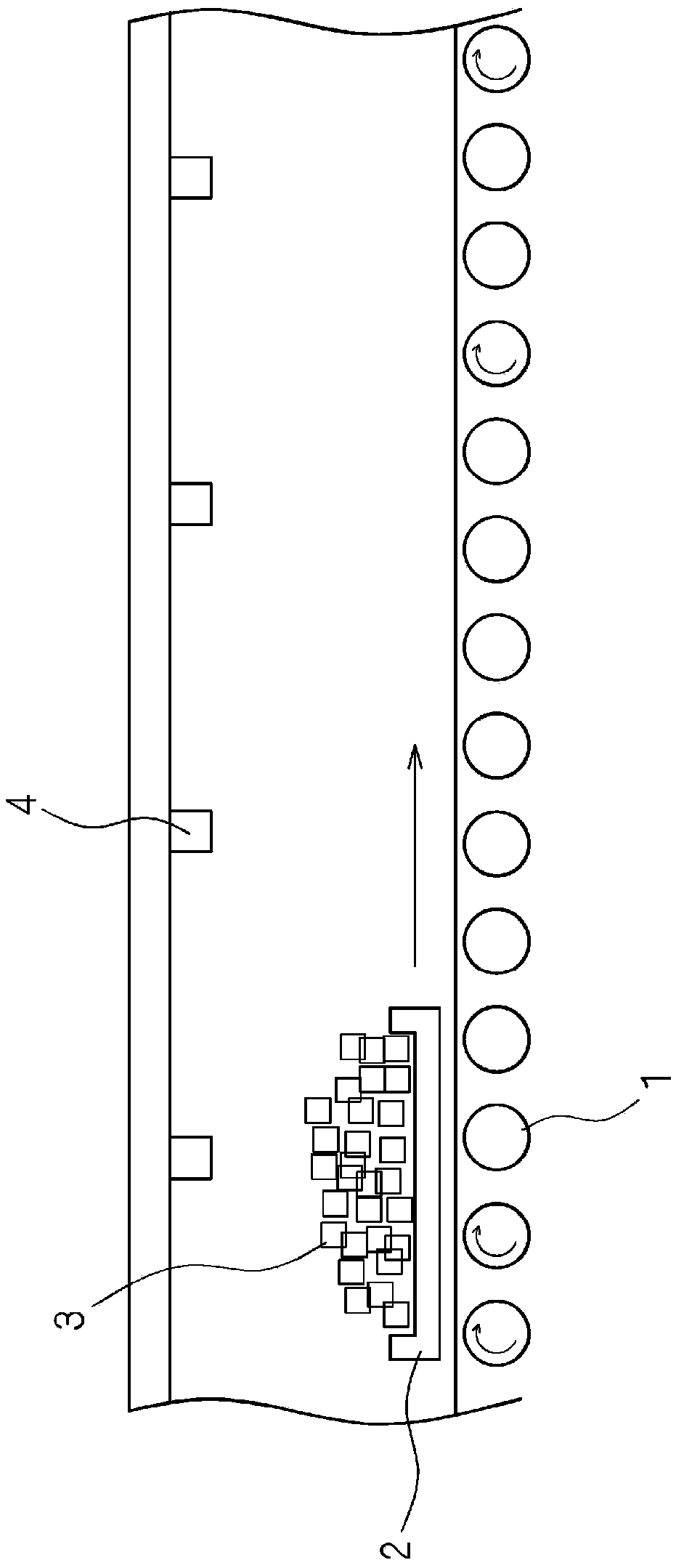

[0036] figure 1 It is a schematic diagram showing the structure of a heating device using a conventional heat treatment jig. exist figure 1 In , a so-called roller system heating device is shown. Such as figure 1 As shown, a plurality of rotatable rollers 1 are provided on the bottom surface of the furnace of the heating furnace (heat treatment furnace) of the heating device, and chip-shaped (ceramic) electronic components 3, such as chip-shaped ceramic capacitors, chip-shaped inductors, etc. The stacked bodies are randomly stacked on the mounting surface of the jig 2 for heat treatment, and they are passed in the heating furnace in the direction of the arrow in the figure. The heated ambient gas is jetted from the gas jet port 4 in the upper part of the heating furnace to heat-treat the chip-shaped electronic component 3 passing therethrough. Of course, the gas ejection port 4 is not limited to be provided in the upper part of the heating furnace, and may be provided in t...

Embodiment approach 2

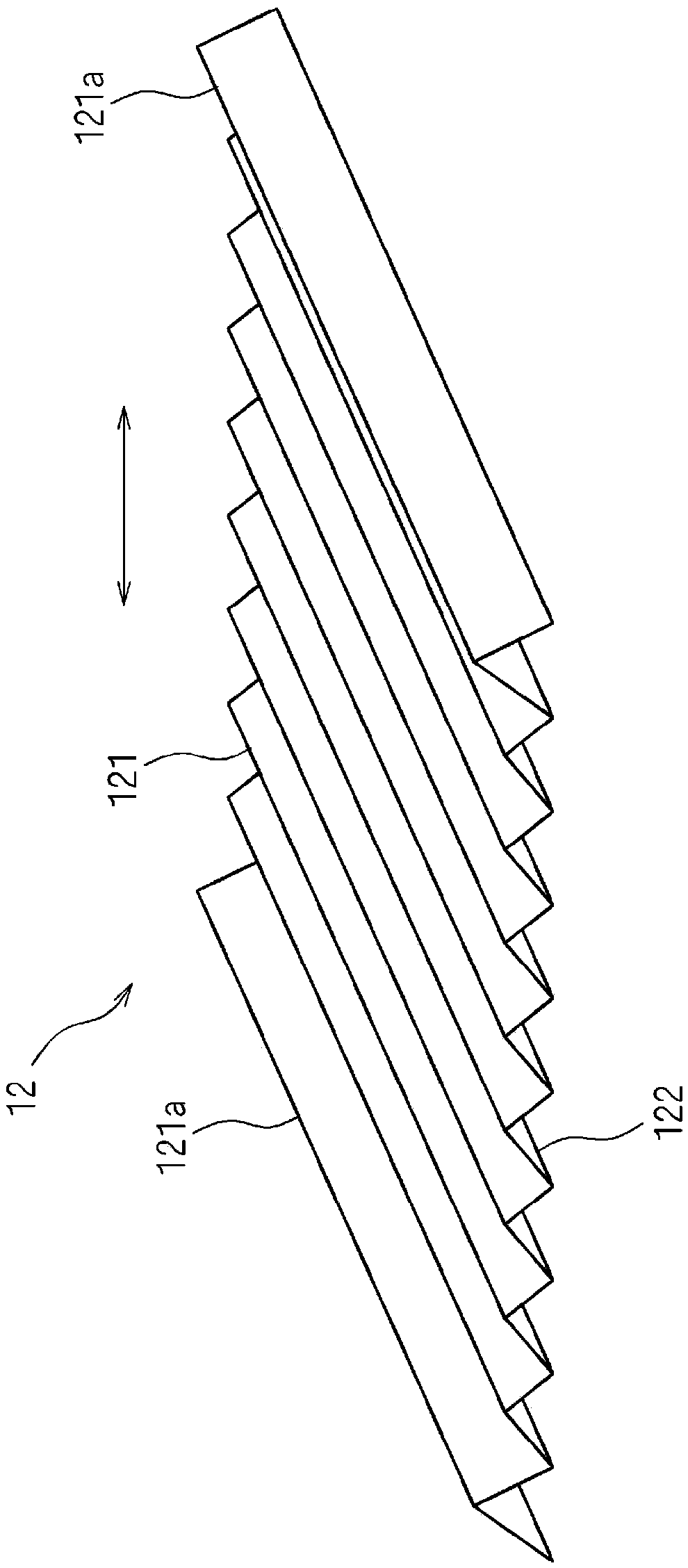

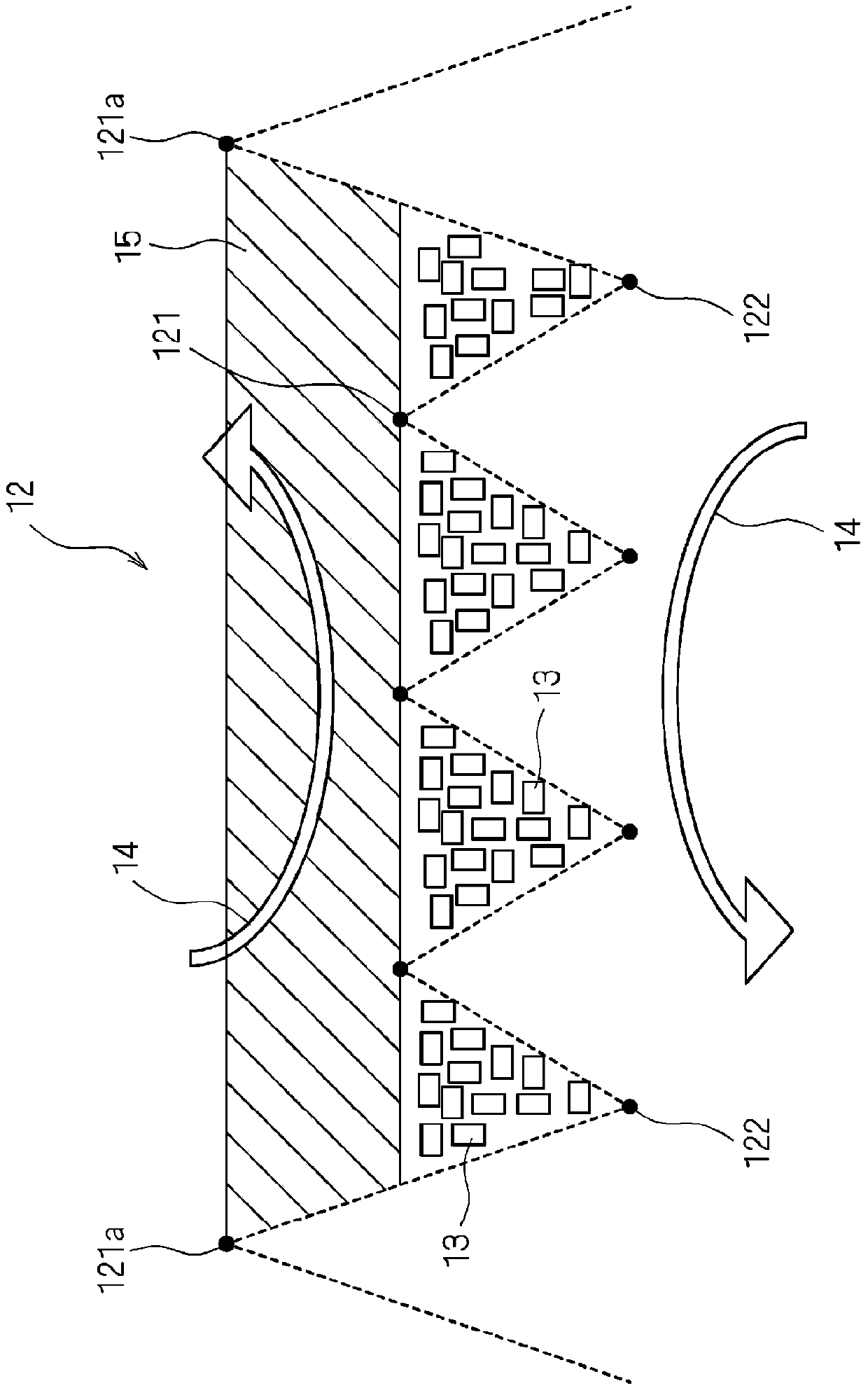

[0051] The jig for heat treatment in Embodiment 2 is the same as Embodiment 1 in the following respects: it includes a mounting surface with a plurality of through holes, and the mounting surface is composed of folded concave-convex surfaces with alternately folded peaks and folded valleys. The tops of the folded peaks at or near both ends of the jig are higher than the heights of the tops of the other folded peaks. However, the mounting surface on which chip-shaped electronic components are placed has the lowest height at the top of the central folded peak, and the height of the top of the folded peak gradually increases toward both ends, which is different from that of the embodiment. One is different.

[0052] Figure 4 It is a schematic cross-sectional view when chip-shaped electronic components 13 are placed on heat treatment jig 12 according to Embodiment 2 of the present invention. Such as Figure 4 As shown, the mounting surface of the heat treatment jig 12 is made ...

Embodiment approach 3

[0059] The jig for heat treatment in Embodiment 3 is the same as Embodiment 1 and Embodiment 2 in the following aspects: it includes a mounting surface with a plurality of through holes, and the mounting surface is a wrinkled concave-convex surface that alternately repeats folded peaks and folded valleys. In this configuration, the tops of the folded peaks located at or near both ends in the folding direction are higher than the tops of the other folded peaks. However, it is different from Embodiment 1 and Embodiment 2 in that the mounting surfaces on the side closer to both ends in the folding direction are erected vertically for each group of mounting surfaces adjacent to each other via the folded peak portion.

[0060] Figure 5 It is a schematic cross-sectional view when a chip-shaped electronic component is placed on the heat treatment jig 12 according to Embodiment 3 of the present invention. Such as Figure 5 As shown in (a), the mounting surface of the heat treatment...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com