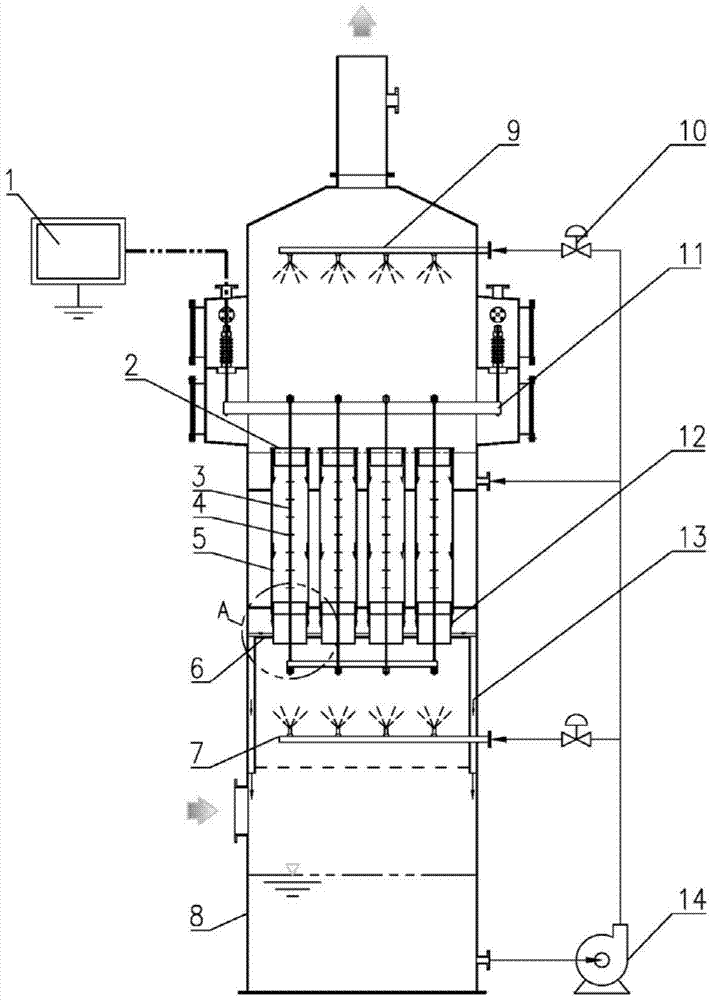

A water film forming device for a wet electrostatic precipitator

A wet electrostatic and precipitator technology, applied in the field of machinery, can solve the problems of cleaning, hinder the smooth discharge of the discharge electrode, and difficult to fully discharge the electrode, and achieve the effect of prolonging the cleaning cycle, preventing dust pollution and reducing maintenance costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

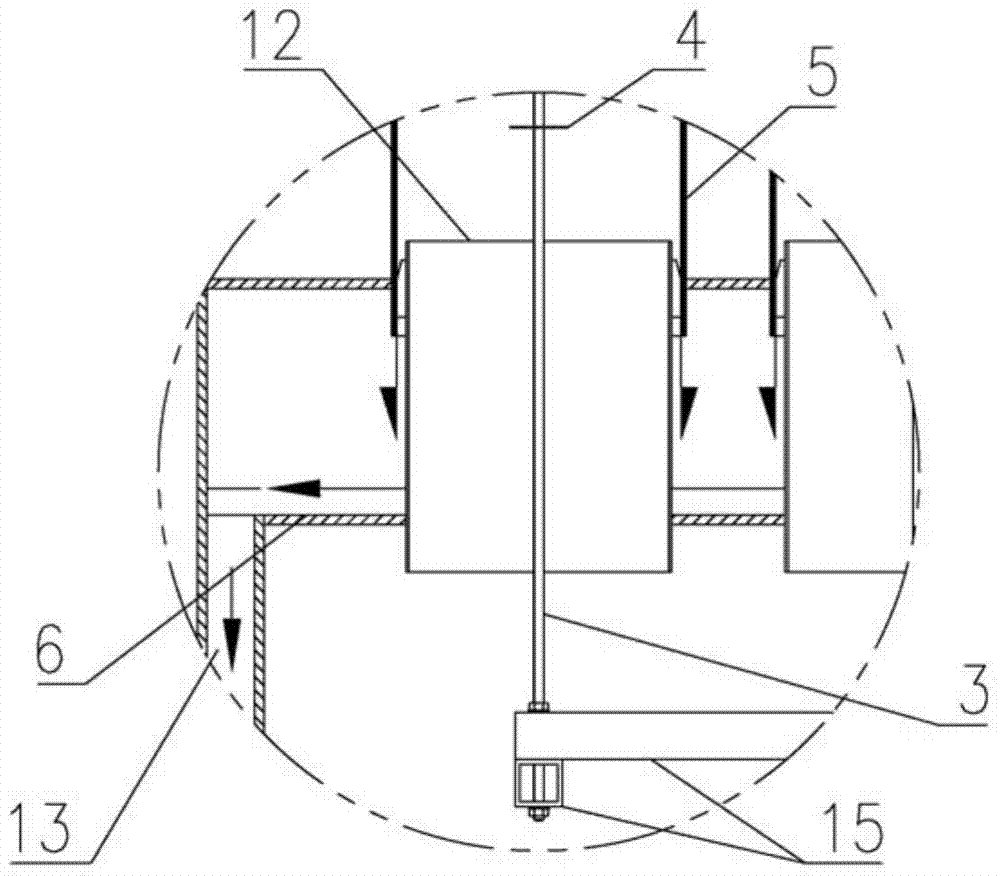

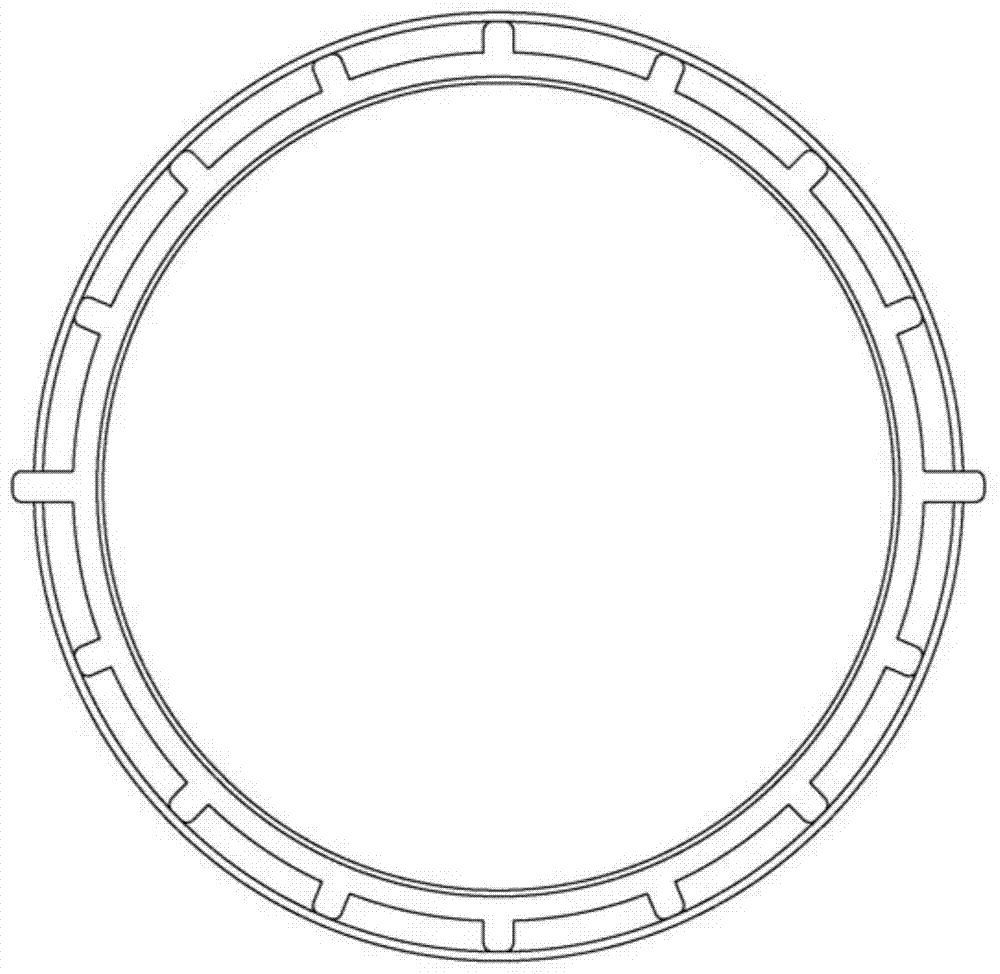

[0029] Embodiment 1: A water film forming device for a wet electrostatic precipitator, the water film forming device 2 is arranged on the upper part of the dust collecting pole 5, and the water film forming device 2 includes a water inlet and a guide uniformly distributed below the water inlet. The flow channel, the diversion channel has an angle of 45° with the vertical direction, so that the water film can form a swirl flow with an inclined angle as a whole, and the water film area is wider than that without an inclined angle, so through multiple The water film formed by the inclined diversion groove can cover the entire inner wall of the dust collecting pole 5 . The upper part of the dust collecting pole 5 is provided with a water tank, and the water used to form the water film continuously flows into the water tank, and the water overflowing from the water tank enters the inside of the dust collecting pole 5 through the hole in the upper part of the dust collecting pole 5, ...

Embodiment 2

[0030] Embodiment 2: A water film forming device for a wet electrostatic precipitator, the water film forming device 2 is arranged on the upper part of the dust collecting pole 5, and the water film forming device 2 includes a water inlet part and guides evenly distributed below the water inlet part. The flow channel, the diversion channel has an angle of 60° with the vertical direction, so that the water film can form a swirling flow with an inclined angle as a whole, and the area of the water film is wider than that without an inclined angle, so through multiple The water film formed by the inclined diversion groove can cover the entire inner wall of the dust collecting pole 5 . The upper part of the dust collecting pole 5 is provided with a water tank, and the water used to form the water film continuously flows into the water tank, and the water overflowing from the water tank enters the inside of the dust collecting pole 5 through the hole in the upper part of the dust c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com