Method for detecting surface of hot plate

A detection method and hot plate technology, applied in the field of detection, can solve problems such as affecting heat conduction efficiency, chip cracking, affecting product qualification rate, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

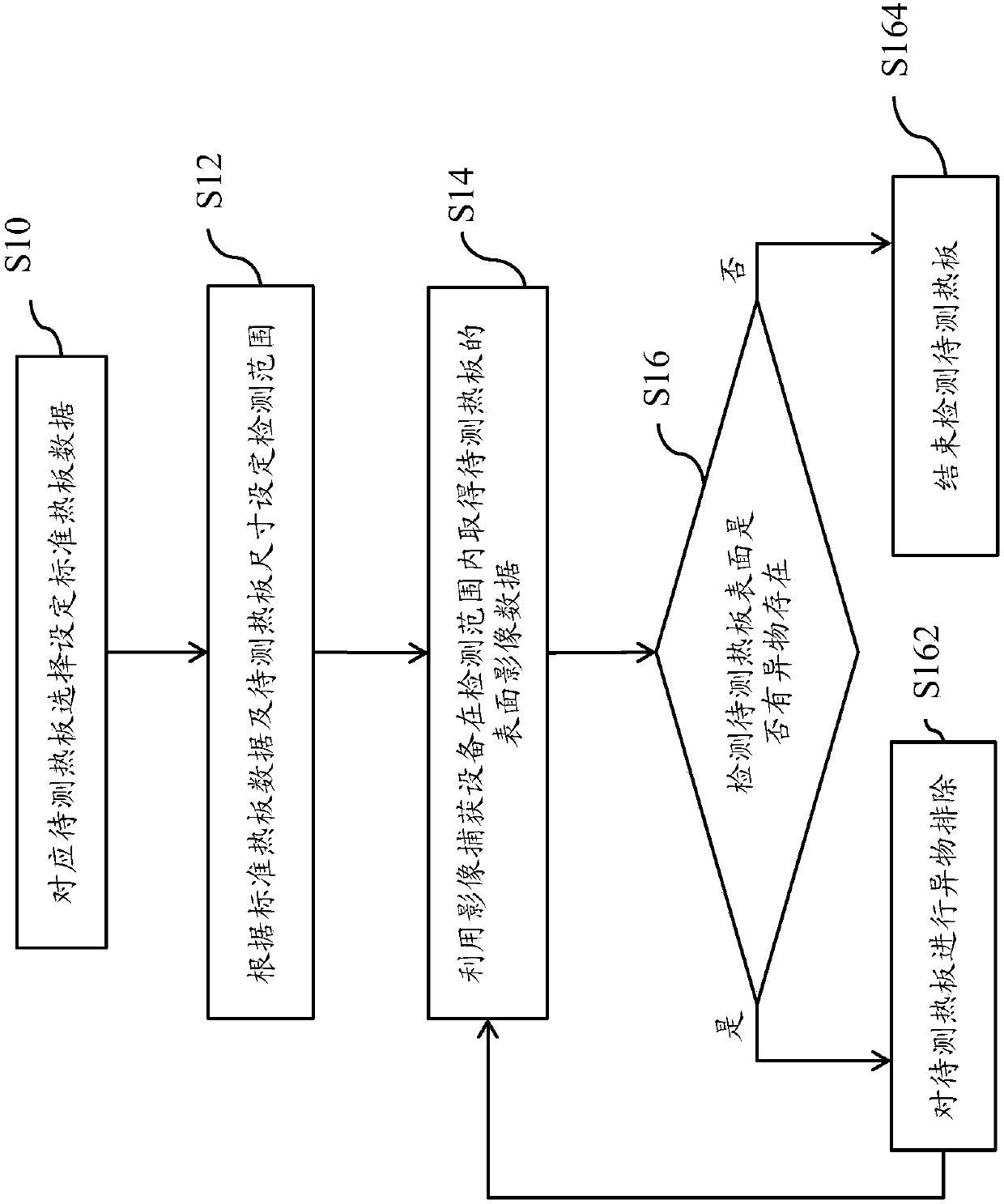

[0026] In order to improve the detection result of the hot plate, the present invention uses a set of standardized detection process to replace the traditional manual visual inspection, so as to provide the hot plate with a very high pass rate for users to use.

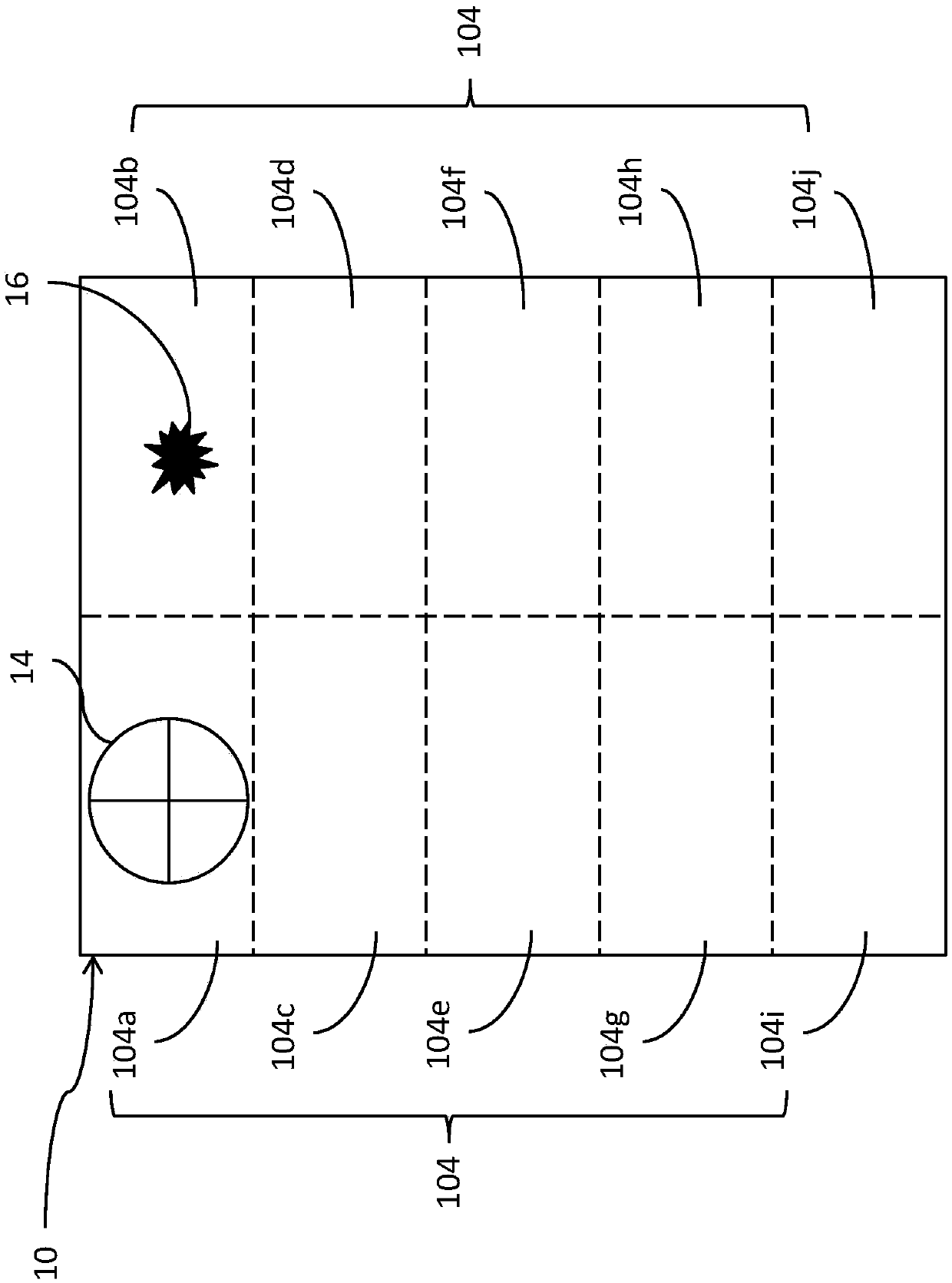

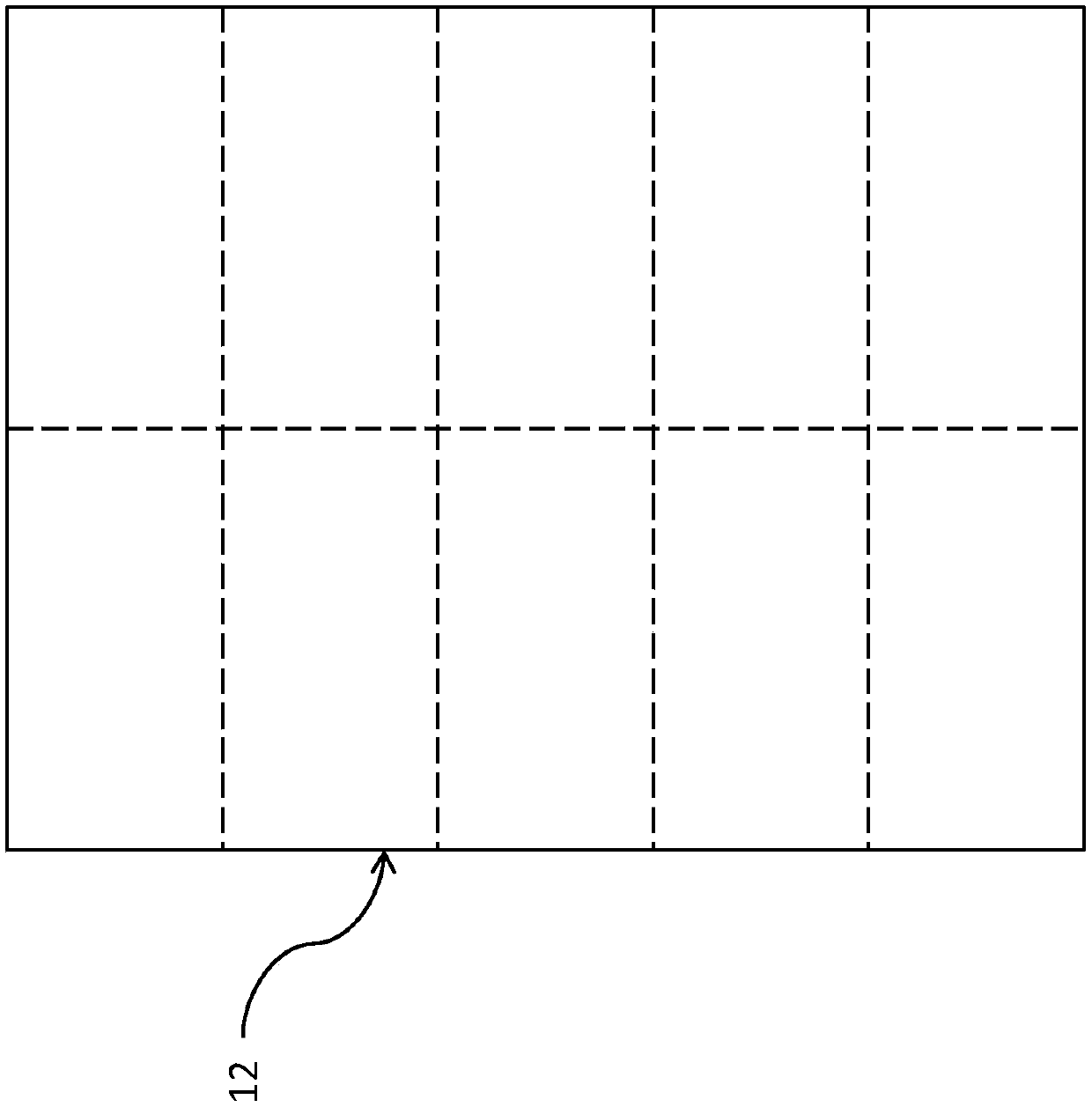

[0027] First of all, the hardware facility is firstly explained for the detection method of the hot plate surface of the present invention. The detection method of the present invention is used to detect whether there is foreign matter on the surface of the hot plate to be tested, and the detection method of the hot plate surface of the present invention is mainly Utilize the machine platform (not shown in the figure) that detects hot plate, in conjunction with the control of computer software program, can allow the user to carry out the detection of qualified rate of hot plate to be tested before using hot plate, the present invention is not limited to be used for producing hot plate The specification or form of the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com