Roller Dust Collector

A technology of dust collector and roller, which is applied in the direction of chemical instruments and methods, separation of dispersed particles, filtration of dispersed particles, etc., can solve the problems of increasing equipment running resistance, potential safety hazards of dust collectors, etc., to reduce the possibility of dust explosion and facilitate Manufacturing, dust explosion reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

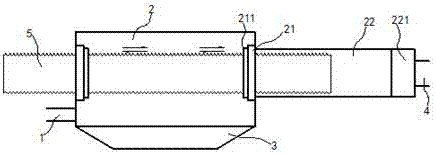

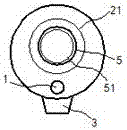

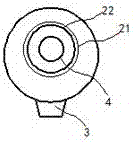

[0015] exist Figure 1 to Figure 3 In the shown embodiment, the roller dust collector includes an air intake pipe 1, a dust removal chamber 2, an ash hopper 3 and an exhaust pipe 4; the cylindrical dust removal chamber 2 is placed horizontally on the body; the ash hopper 3 is installed in the lower part of the dust removal chamber 2, and the air inlet pipe 1 is placed on the left side wall of the dust removal chamber 2; drive rings 21 are symmetrically installed on the left and right side walls of the dust removal chamber 2, so that The drive ring 21 is driven to rotate by the drive motor; the inner ring surface of the drive ring 21 is engraved with threaded grooves; a cleaning brush 211 is installed on the side ring edge of the drive ring 21; The dust removal roller 5, in the present embodiment, the length of the dust removal roller 5 is at least twice the length of the dust removal chamber 2; the two ends of the dust removal roller 5 extend out of the dust removal chamber 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com