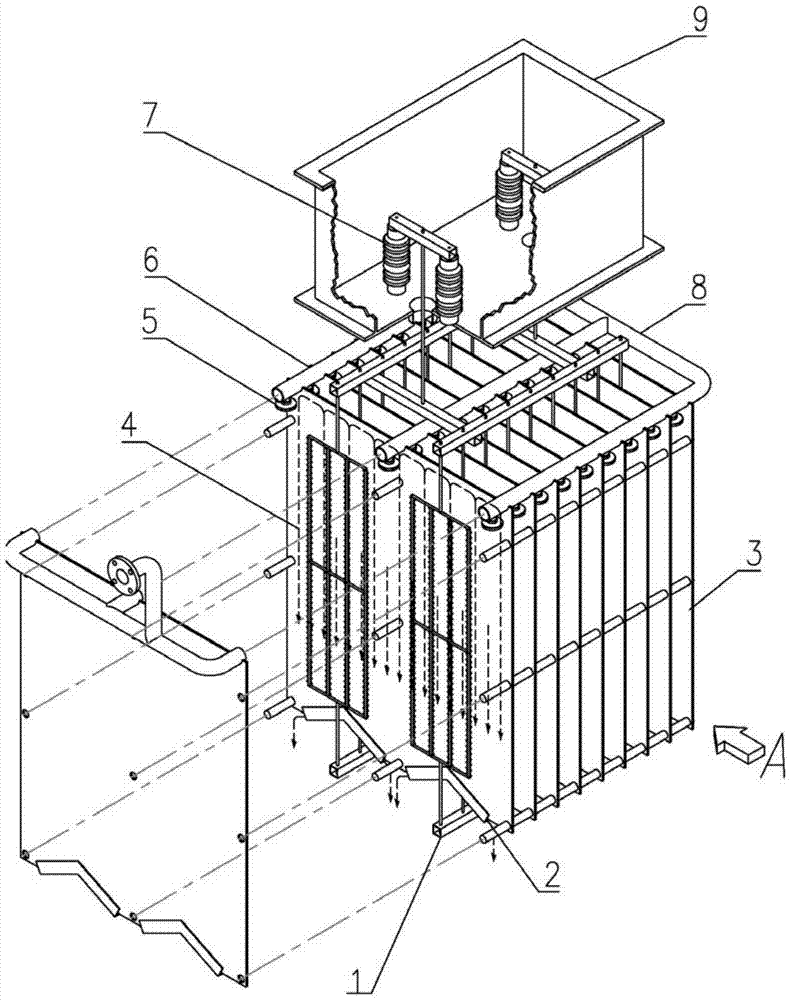

A horizontal wet electrostatic precipitator water film forming device

A wet electrostatic and precipitator technology, applied in the field of machinery, can solve the problems such as the inability to effectively clean the electrodes, the huge water flow, and the difficulty of the electrodes being fully integrated, so as to avoid the phenomenon of spark discharge, reduce human resources, and reduce maintenance costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

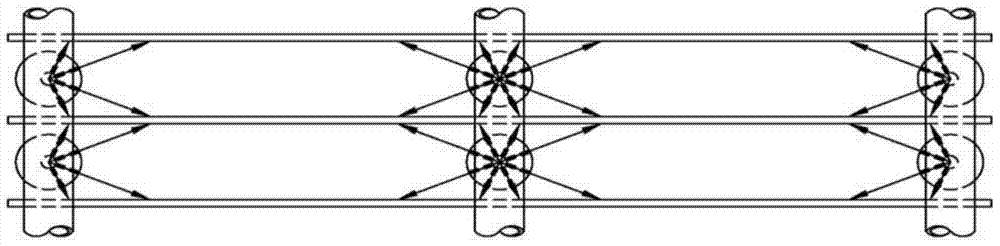

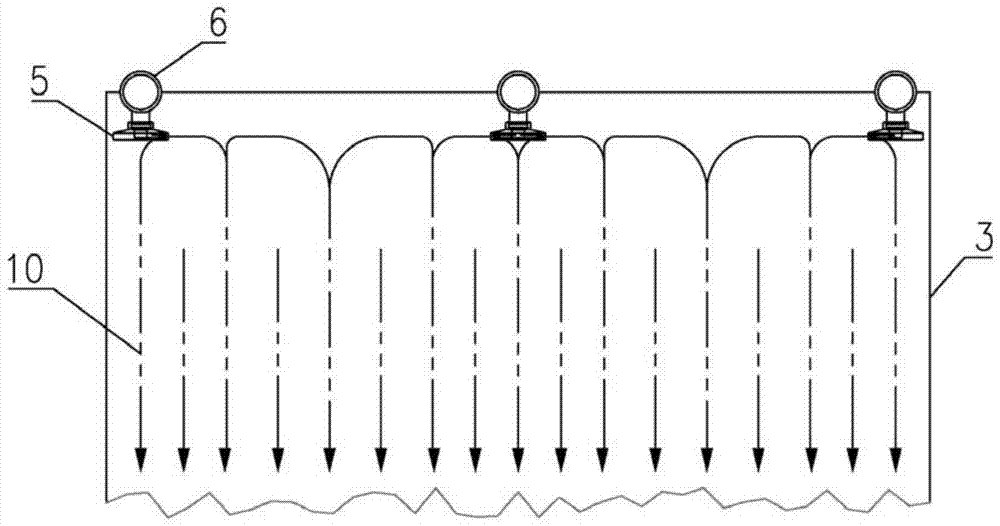

[0039] Embodiment 1: A water film forming device for a horizontal wet electrostatic precipitator, including a spray main pipe 6 arranged on the electrostatic precipitator, and a nozzle installation head 12 arranged under the spray main pipe 6 and the nozzle installation head 12 A connected nozzle 5, the nozzle 5 includes a connecting part and a liquid spraying chamber arranged below the connecting part, and a plurality of liquid spraying holes are distributed on the liquid spraying chamber. The liquid spray chamber is disc-shaped, and the liquid spray holes are distributed on the circumference of the liquid spray chamber. The liquid spray chamber is provided with 8 liquid spray holes, the central angle of the arc between two adjacent liquid spray holes is 42° or 48°, and any two of the three adjacent liquid spray holes The central angles of the arcs are different. In some embodiments, the ratio of the length to the diameter of the spray hole is 5 or more. A throttling orific...

Embodiment 2

[0040] Embodiment 2: A water film forming device for a horizontal wet electrostatic precipitator, including a spray main pipe 6 arranged on the electrostatic precipitator, and a nozzle installation head 12 arranged under the spray main pipe 6 and the nozzle installation head 12 A connected nozzle 5, the nozzle 5 includes a connecting part and a liquid spraying chamber arranged below the connecting part, and a plurality of liquid spraying holes are distributed on the liquid spraying chamber. The liquid spray chamber is disc-shaped, and the liquid spray holes are distributed on the circumference of the liquid spray chamber. The liquid spray chamber is provided with 8 liquid spray holes, the central angle of the arc between two adjacent liquid spray holes is 42° or 48°, and any two of the three adjacent liquid spray holes The central angles of the arcs are different. In some embodiments, the ratio of the length to the diameter of the spray hole is 5 or more. A throttling orific...

Embodiment 3

[0041]Embodiment 3: A water film forming device for a horizontal wet electrostatic precipitator, including a spray main pipe 6 arranged on the electrostatic precipitator, and a nozzle installation head 12 arranged under the spray main pipe 6 and the nozzle installation head 12 The connected nozzle 5 and the throttle orifice 11 arranged between the nozzle installation head 12 and the nozzle 5, the nozzle 5 includes a connection part and a liquid spray chamber arranged below the connection part, and there are many nozzles distributed on the liquid spray chamber. a spray hole. The liquid spray chamber is disc-shaped, and the liquid spray holes are distributed on the circumference of the liquid spray chamber. There are 4 spray holes on the semicircle of the spray chamber, the central angle of the circular arcs of two adjacent spray holes is 42° or 48°, and any two spray holes in the three adjacent spray holes The center angle of the arc differs between the holes. The ratio of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com