Novel continuous bending equipment

A new type of equipment and technology, applied in the direction of heat exchange equipment, etc., to achieve the effect of convenient use, high safety, and increase the efficiency of pipe bending

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

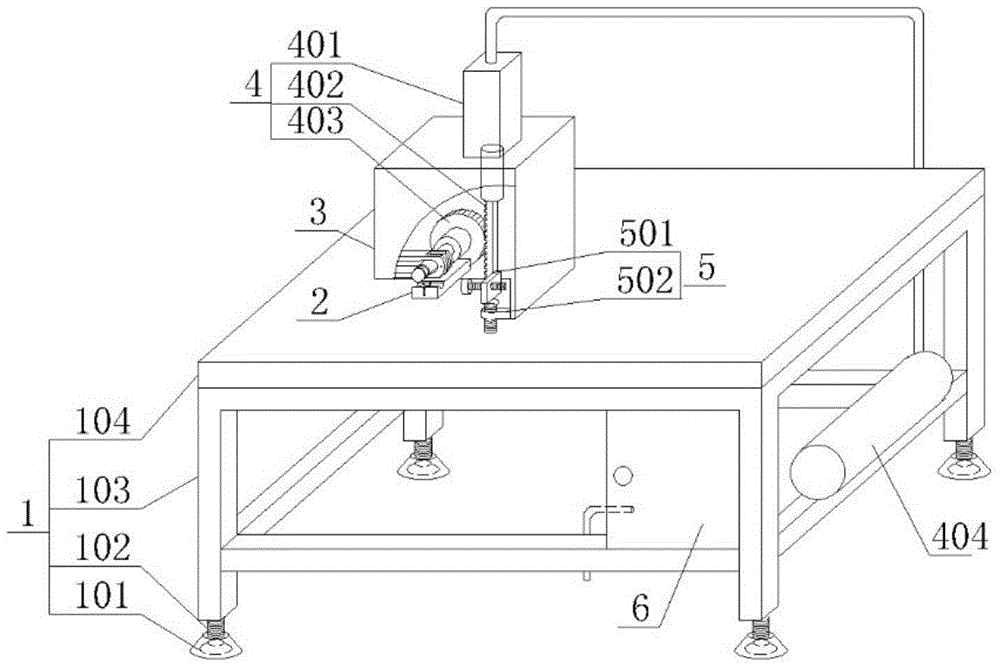

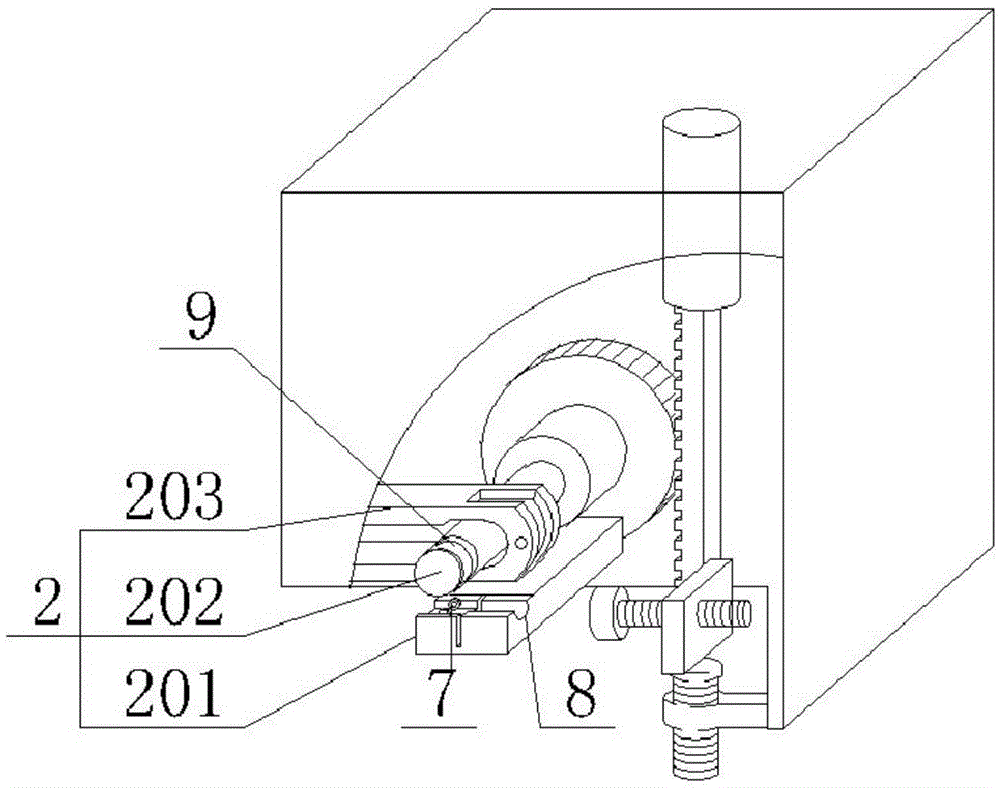

[0013] See accompanying drawing: A kind of novel continuous elbow equipment is characterized in that it comprises support platform 1, pipe bending mold 2, limit mechanism 5, power mechanism 4, body protective shell 3 and electric control box 6, and described support platform 1 is composed of The platform 103 is composed of a support plate 104. There are adjustable feet 102 at the bottom of the platform 103. The pipe bending mold 2 includes a pipe bending lower die 201, a pipe bending die head 202 and a 'U'-shaped stopper 203. The position mechanism 5 is divided into a pipe limit mechanism 501 and a stroke limit mechanism 502. The power mechanism 4 includes a power cylinder 401, an air pressure tank 404, a rack 402 and a rotating shaft 403 with gears. It is made of steel plate less than 5mm, and there is a fan-shaped window on the front of the body protection shell 3. The electric control box 6 is installed on the stand, and the electric control box 6 is equipped with a groundin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com