Inclined spring supporting mechanism based on horizontal indication

A technology of support mechanism and inclined spring, applied in metal processing mechanical parts, maintenance and safety accessories, metal processing equipment, etc., can solve the problems of easily damaged internal parts, short service life, poor buffering effect of machine tools, etc., to achieve reliability High, good buffering effect, small vibration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

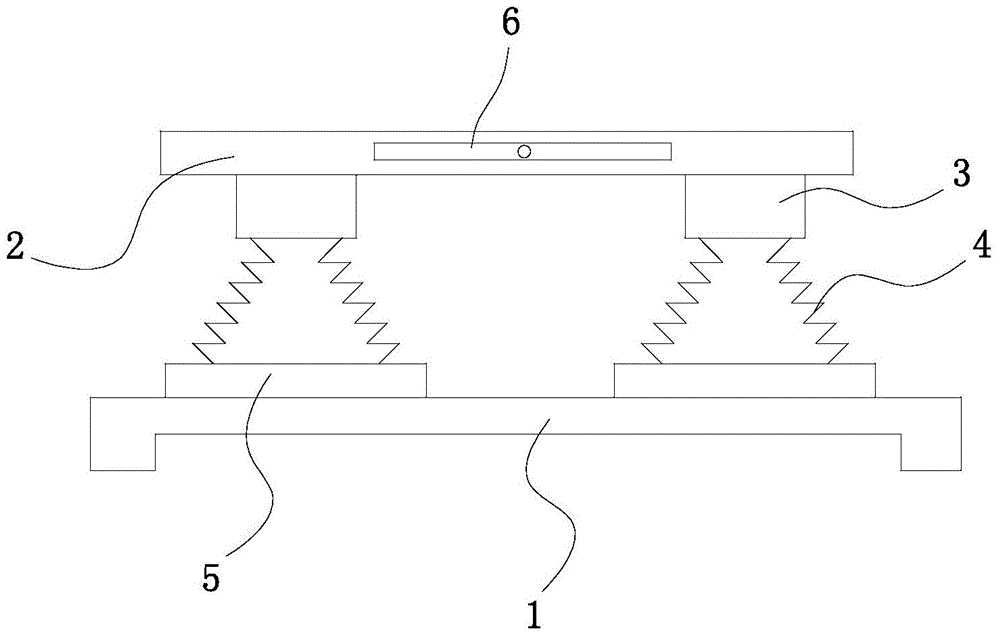

[0011] Such as figure 1 As shown, the oblique spring support mechanism based on the horizontal indication of the present embodiment includes a support plate 2, and the lower surface of the support plate 2 is symmetrically equipped with a short column 3, and the lower surface of the short column 3 is equipped with a spring 4 that is arranged obliquely. The lower ends are respectively fixed on the bottom plate 5, and the bottom plate 5 is symmetrically installed on the base 1;

[0012] The side device of the support plate 2 has a horizontal indicator bar 6, and the horizontal indicator bar 6 is used to indicate the levelness of the support plate 2, that is, to adjust the levelness of the machine tool.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com