Optical binding device and method

An optical bonding and optical device technology, applied in the optical field to reduce air bubbles and increase production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

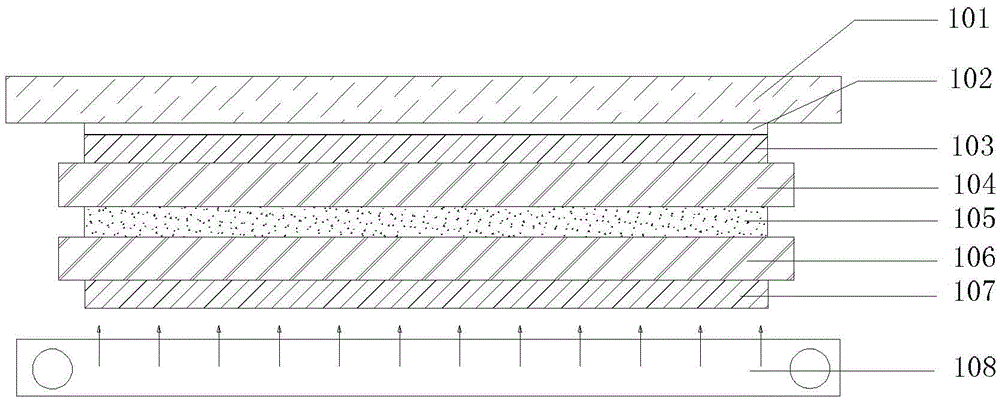

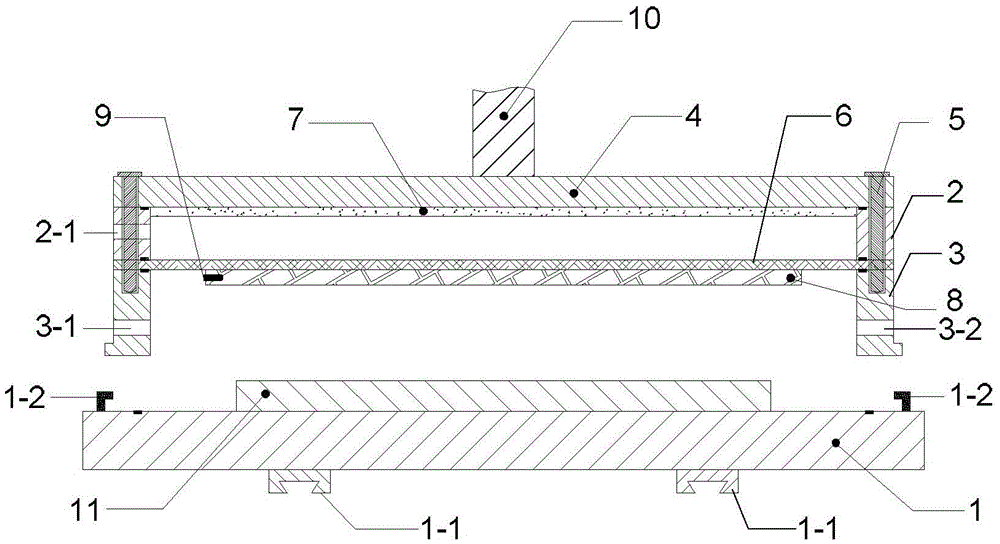

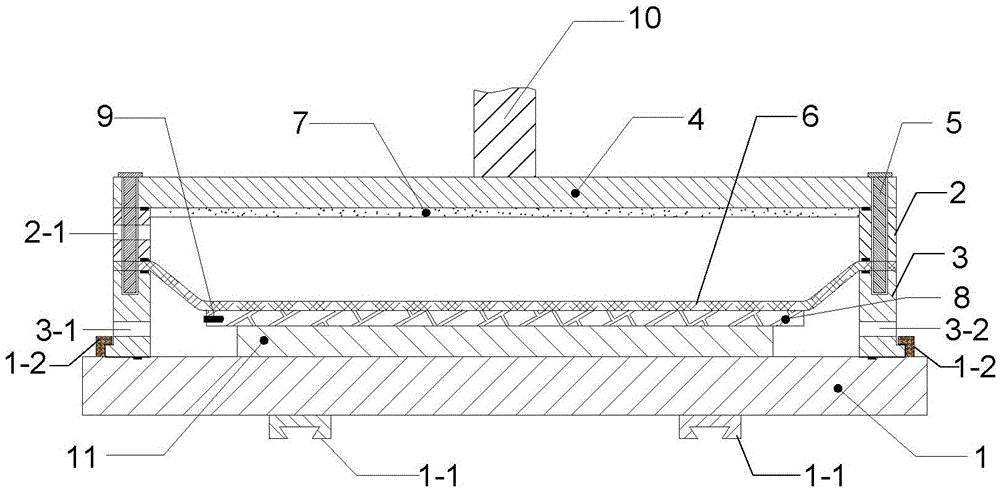

[0033] Specific implementation mode one: the following combination figure 2 and image 3 Describe this embodiment, the optical binding device described in this embodiment includes a carrying unit and a working cavity unit; the carrying unit is used to carry the optical device 11 to be bonded, and the working cavity unit is used to provide the optical device to be bonded. Pressure and thermal environment to bind the optical components to be bonded together;

[0034] The bearing unit comprises a bearing platform 1, two mutually parallel sliders 1-1 are arranged on the lower surface of the bearing platform 1, and the bearing platform 1 moves on the slide rail through the two sliders 1-1; The buckles 1-2 are parallel to each other, and the extension direction of the slider 1-1 and the buckle 1-2 is the extension direction of the slide rail;

[0035] The working chamber unit includes a pressurized chamber and a vacuum chamber; the pressurized chamber is surrounded by the side wa...

specific Embodiment approach 2

[0048] Specific Embodiment 2: This embodiment is a further description of Embodiment 1, and further includes an insulating layer 7 , and the insulating layer 7 is arranged on the lower surface of the top plate 4 .

[0049] The insulation layer 7 plays the role of heat preservation and reduces energy consumption.

specific Embodiment approach 3

[0050] Embodiment 3: The optical binding method described in this embodiment is implemented based on the optical binding device described in Embodiment 1. The method includes the following steps:

[0051] Step 1. Preparation:

[0052] a. The bearing unit and the working cavity unit are initially separated, and they are arranged separately along the extending direction of the slide rail;

[0053] b. Lift the working cavity unit so that the raised engaging part of the working cavity unit is flush with the buckle 1-2 of the carrying platform 1;

[0054] c. Control the heating layer 8 to be heated to the required working temperature;

[0055] d. placing the optical device 11 to be bonded on the carrying platform 1;

[0056] Step 2: Make the carrying unit slide along the slide rails towards the direction of the working cavity unit, make the raised engaging part of the working cavity unit slide into the buckle 1-2 of the carrying platform 1 along the horizontal direction, and snap t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com