Hub connecting structure of forward propeller and rear propeller of contrarotating propeller

A connection structure and counter-rotating propeller technology, which is applied to ship propulsion, ship parts, ships, etc., can solve the problems of energy loss and insufficient consideration, and achieve the effect of avoiding energy loss and good energy saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

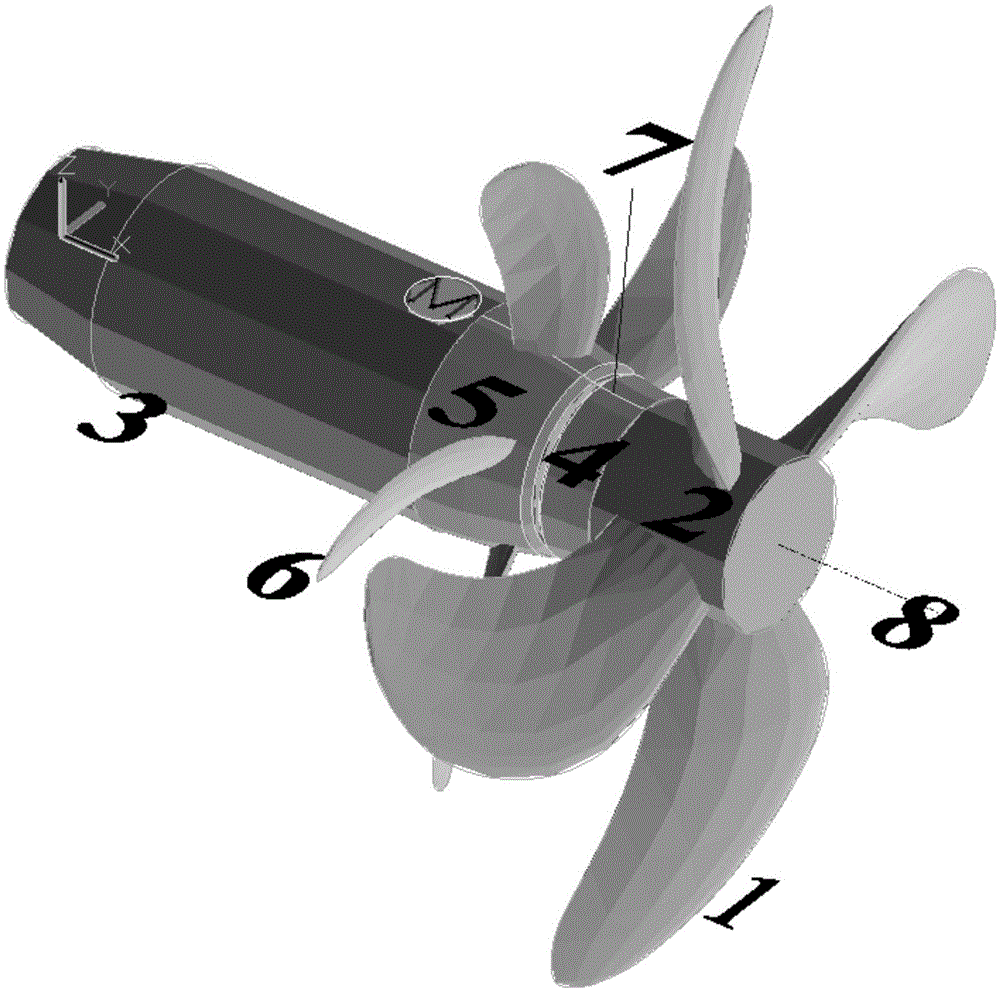

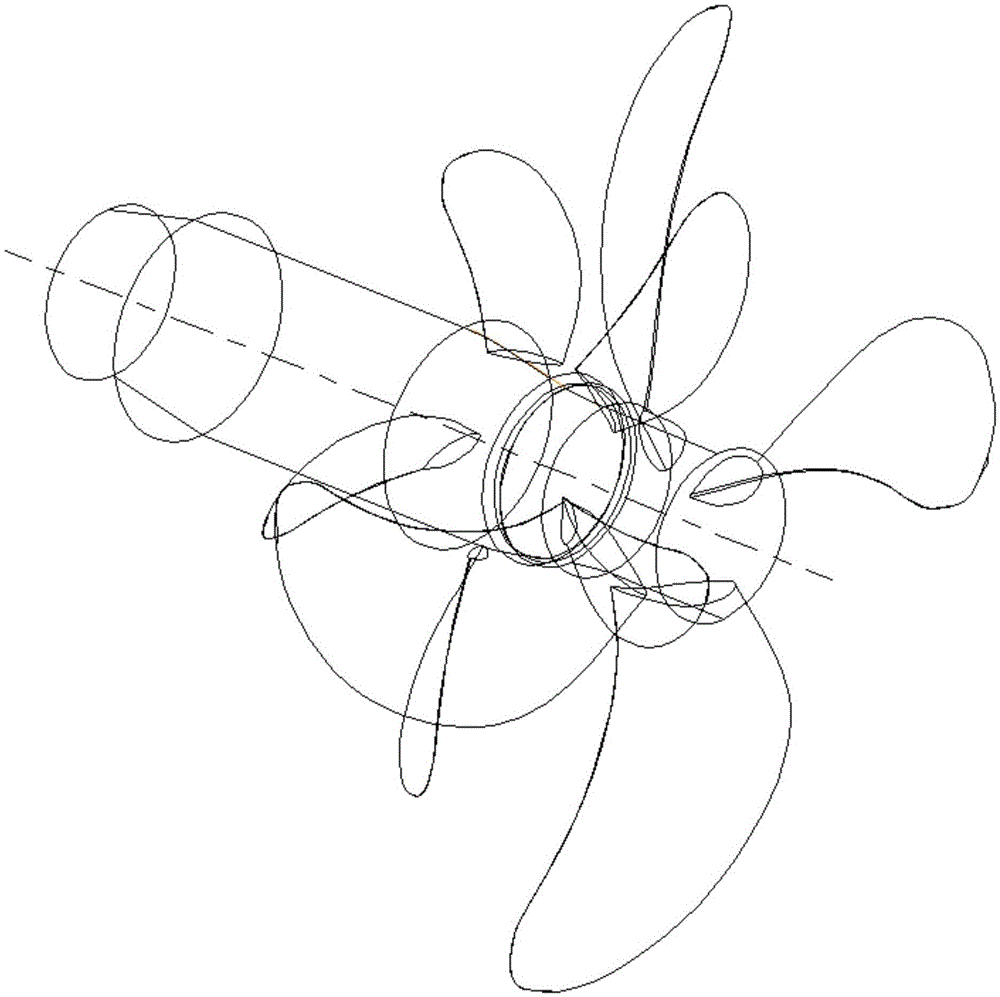

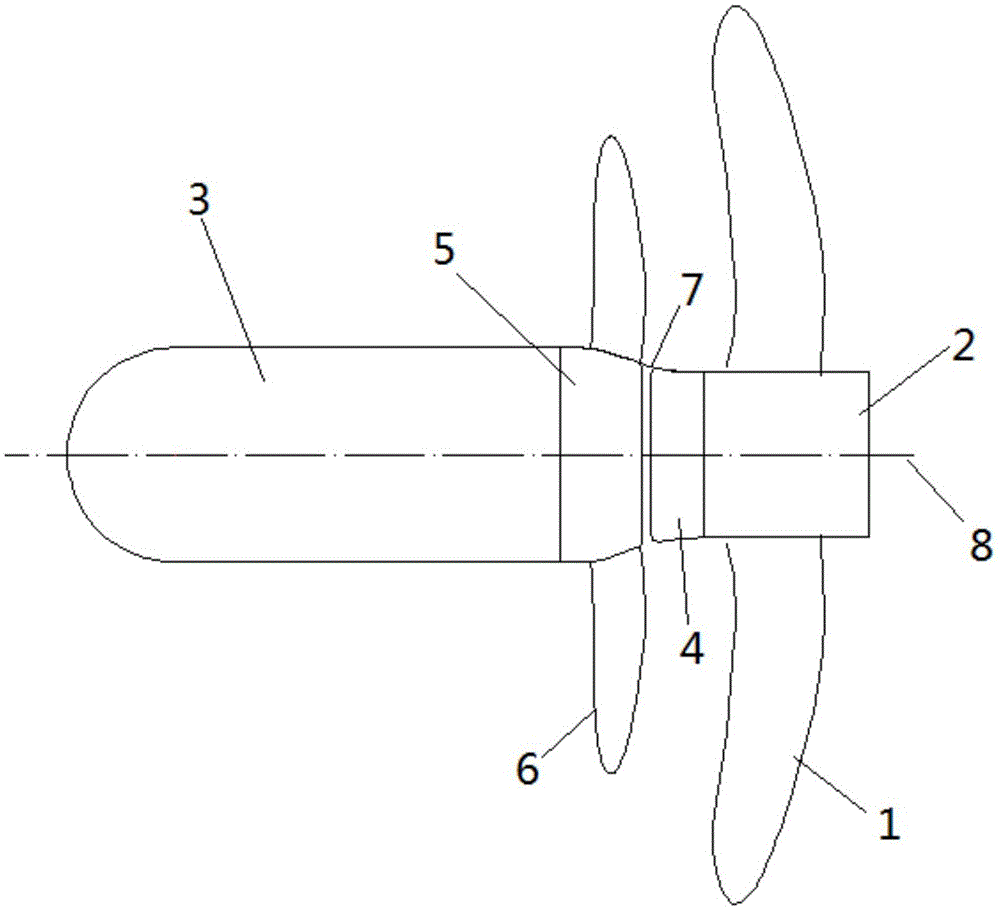

[0022] see Figure 1-Figure 3 , a hub and dome connection type suitable for contra-rotating propeller systems. This design is applied to the hub of the front propeller, the cap of the front propeller and the hub of the rear propeller, and the purpose of energy saving is achieved through the mutual cooperation between the shapes.

[0023] This structure type is mainly composed of unconventional front propeller hub size, special shape front propeller cap, and rear propeller hub shape matching the front propeller wake. Its structural relationship is as follows:

[0024] as attached Figure 1-Figure 3 As shown, the front paddle is composed of three parts 1, 2, and 4; the rear paddle is composed of two parts 5 and 6, and the rear paddle is driven by the motor M in 3; the front and rear paddles are coaxial, and 8 indicates the axis; 7 marks a sect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com