Hybrid electromechanical coolant pump

A coolant pump and coolant technology, which is applied in the direction of engine cooling, mechanical equipment, engine components, etc., can solve problems such as complex operation of mechanical structures, inconsistency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

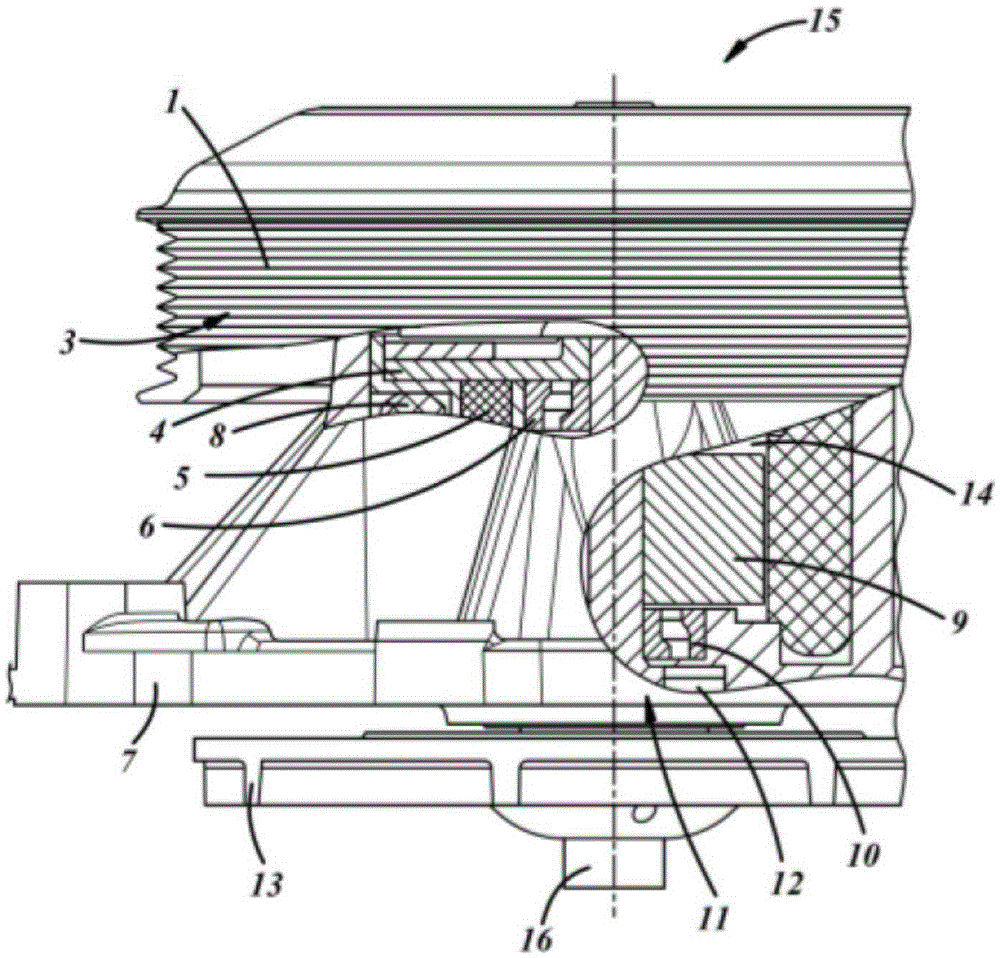

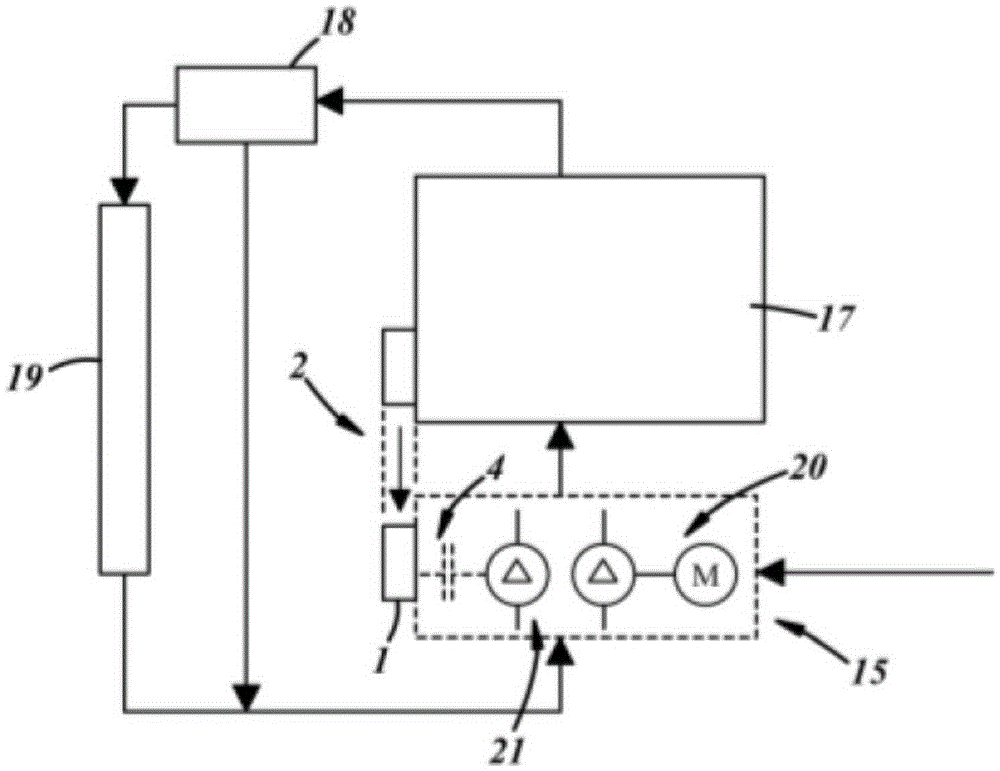

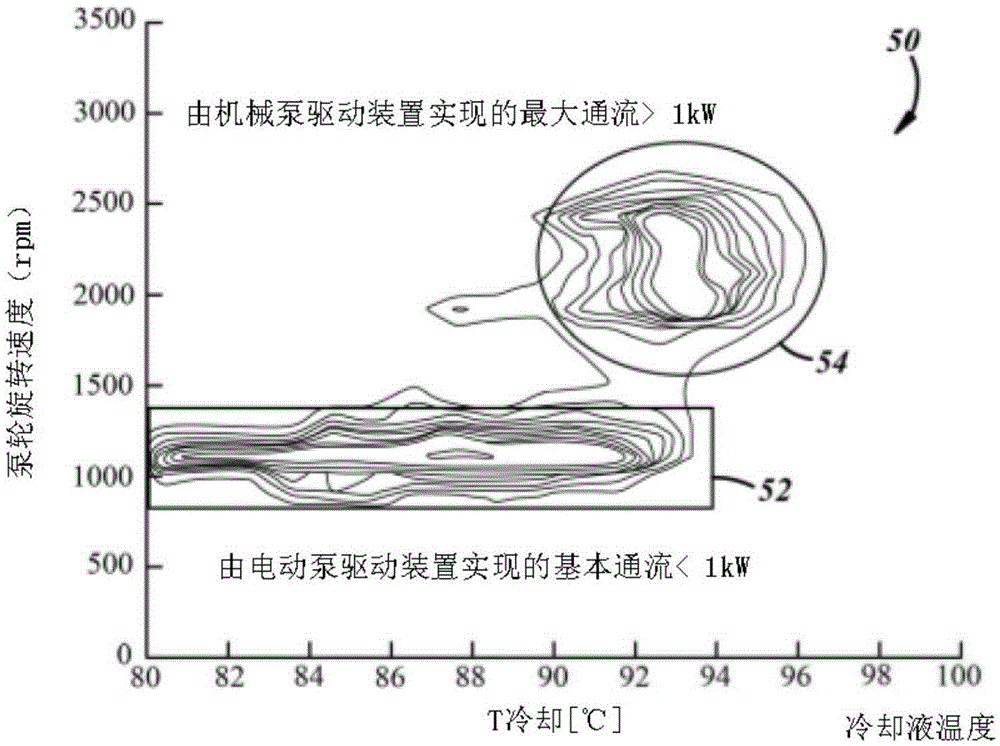

[0033] figure 1 A sectional view through the coolant pump 15 according to one embodiment of the invention is shown. The coolant pump 15 has a pump impeller (also referred to as “impeller”) arranged on a pump impeller shaft (also referred to as “impeller shaft”). The pump impeller shaft is divided into a drive part 3 and a driven part 11 . In the illustrated embodiment, the drive portion 3 is formed as a flange-shaped structure to which the mechanical drive means 1 in the form of a pulley in this example is fixedly connected in a rotatable manner. In the illustrated embodiment, the arrangement consisting of the flange-shaped structure 3 and the pulley 1 is mounted in a housing 7 via bearings 6 .

[0034] The mechanical drive 1 is connectable to an internal combustion engine of a motor vehicle, wherein in the embodiment shown a belt drive can be used. Only the pulley 1 is shown to simplify the description.

[0035] The driven part 11 of the pump wheel (impeller) shaft is mou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com