Combined type evaporative cooling unit

An evaporative cooling and composite technology, which is applied in heating methods, household heating, space heating and ventilation details, etc., can solve the problems of insufficient cooling capacity of the unit, insufficient cooling capacity, large size of the unit structure, etc., and save water consumption. and power consumption, improvement of regional constraints, and small overall structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

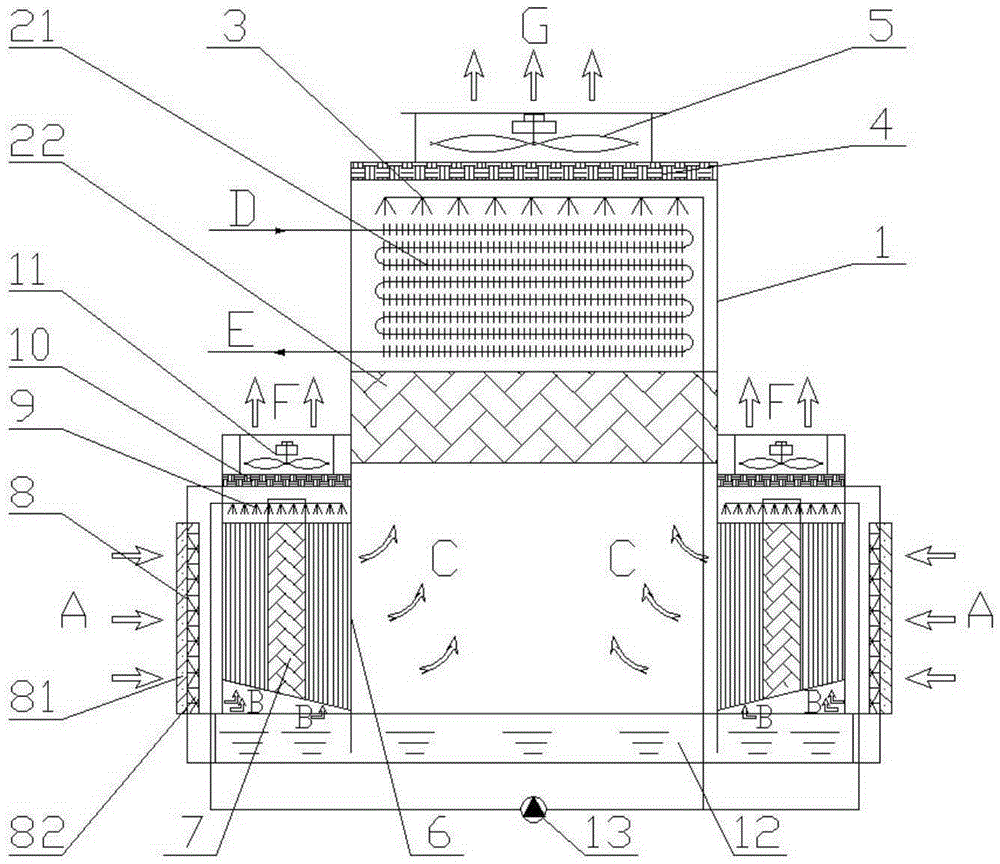

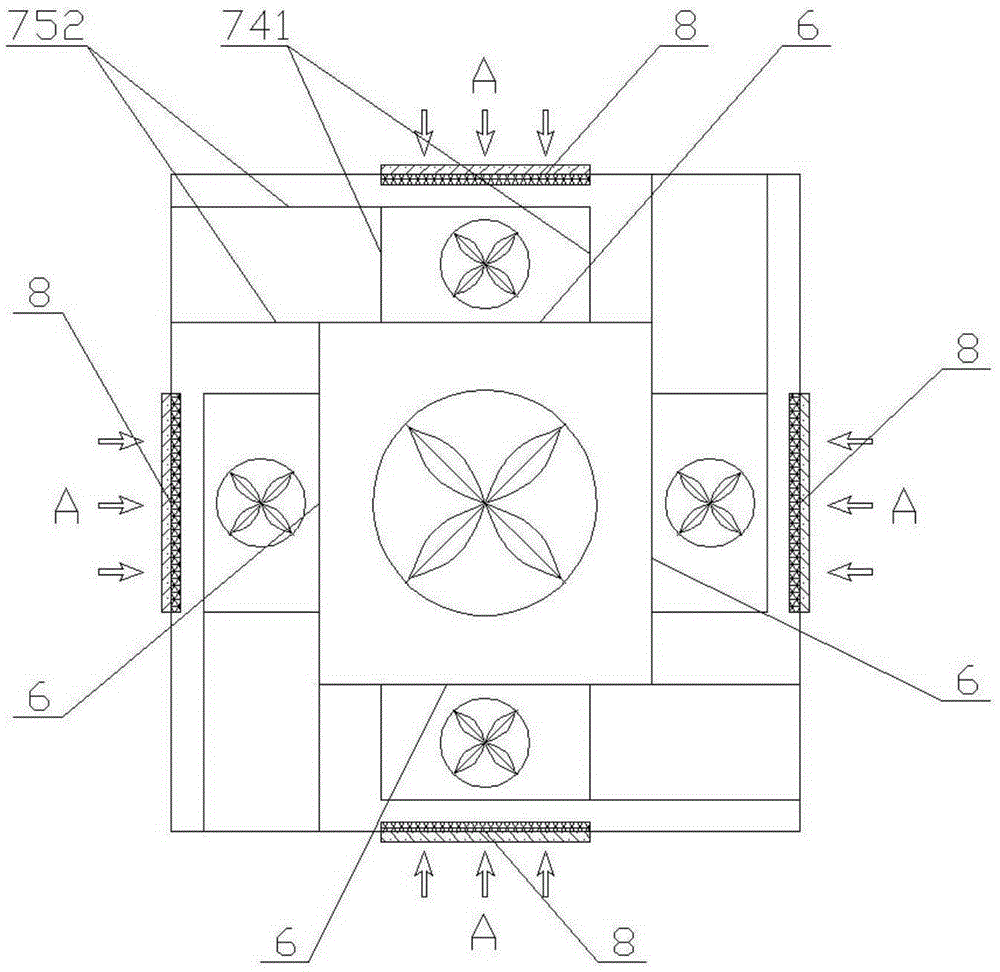

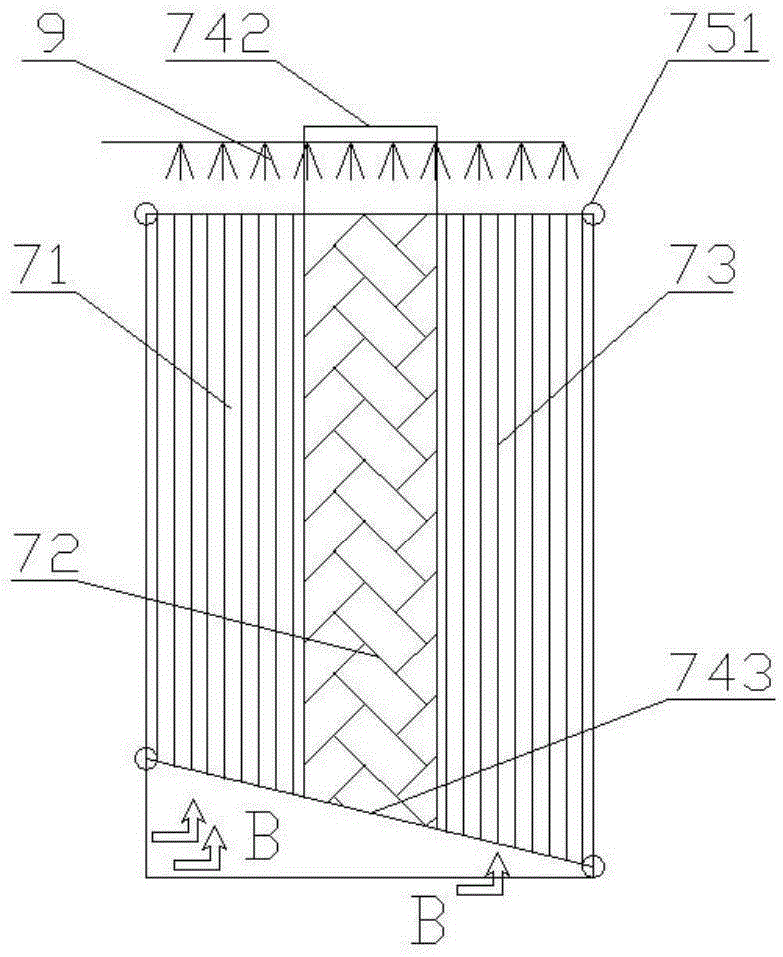

[0025] see figure 1 and figure 2 , in a preferred embodiment of the present invention, a composite evaporative cooling unit 100 includes a housing 1, the housing 1 contains a direct evaporative cooling module and four pre-cooling modules 7, and in the housing 1 is provided with a ventilation opening 8 that allows air to enter the unit 100; preferably, each pre-cooling module 7 is the same, and the ventilation opening 8 is arranged in the middle of each side wall, and The vents 8 are distributed symmetrically on opposite sides, especially, the position, shape and size of the openings of each vent 8 are the same. An air guiding device 81 and a filter 82 are sequentially installed on each vent 8 from the outside to the inside. Preferably, the wind guiding device 81 adopts the form of a rotatable shutter, so that each vent 8 can be selectively usage of. In addition, the outer shell walls of the housing 1 are made of heat-insulating materials and have a sealing effect.

[0026...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com