Pixel unit, infrared imaging detector provided with pixel unit and manufacturing process

A pixel unit and infrared imaging technology, which is applied in the field of infrared detection, can solve problems such as difficult cost reduction, poor reliability, and complicated preparation process, and achieve the effects of small thermal mass, improved fill factor, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings. It should be noted here that the descriptions of these embodiments are used to help understand the present invention, but are not intended to limit the present invention. In addition, the technical features involved in the various embodiments of the present invention described below can be combined with each other as long as they do not constitute a conflict with each other.

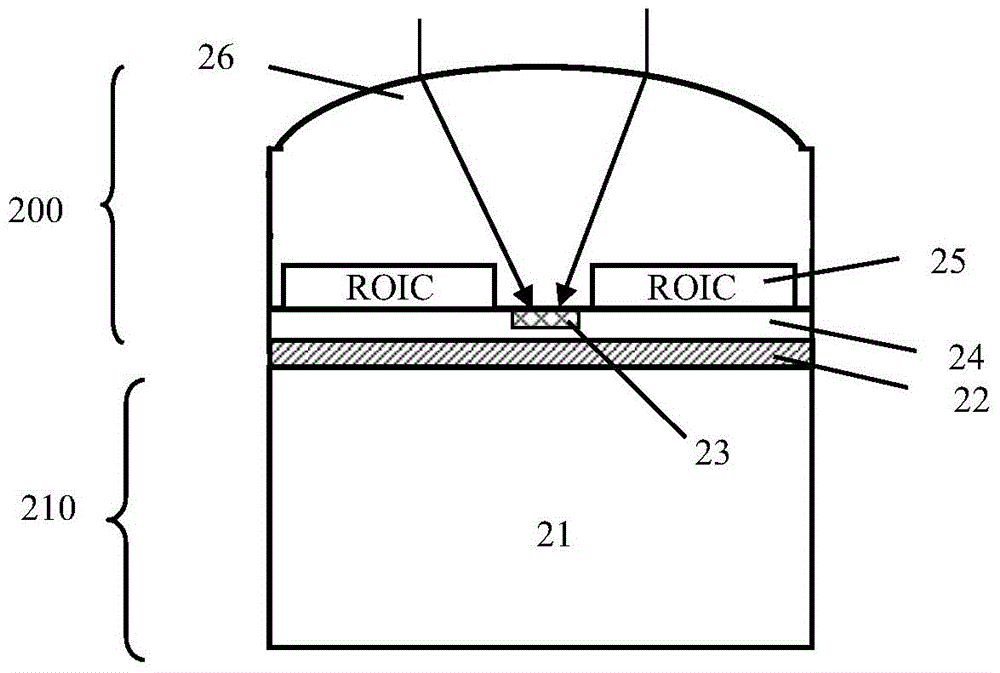

[0030] figure 2 It is a vertical cross-sectional view of a single pixel of an infrared detector. The pixel is mainly formed by bonding a thin silicon-based active sheet 200 and a passive support sheet 210. Therefore, the pixel unit structure after bonding from bottom to top includes: a support layer 21, a bonding layer 22, and a photosensitive unit. 23. A dielectric layer 24, a readout circuit (ROIC) layer 25, and a silicon microlens layer 26.

[0031] The material o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com