Rubber cup protection structure of rubber-cup-type stand pipe pressure sensor

A standpipe pressure and protection structure technology, applied in the direction of measuring fluid pressure, instruments, measuring devices, etc., can solve the problems of easy access, damage to pressure gauges, tearing of rubber cups, etc., to prolong life, reduce instantaneous impact, and install convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

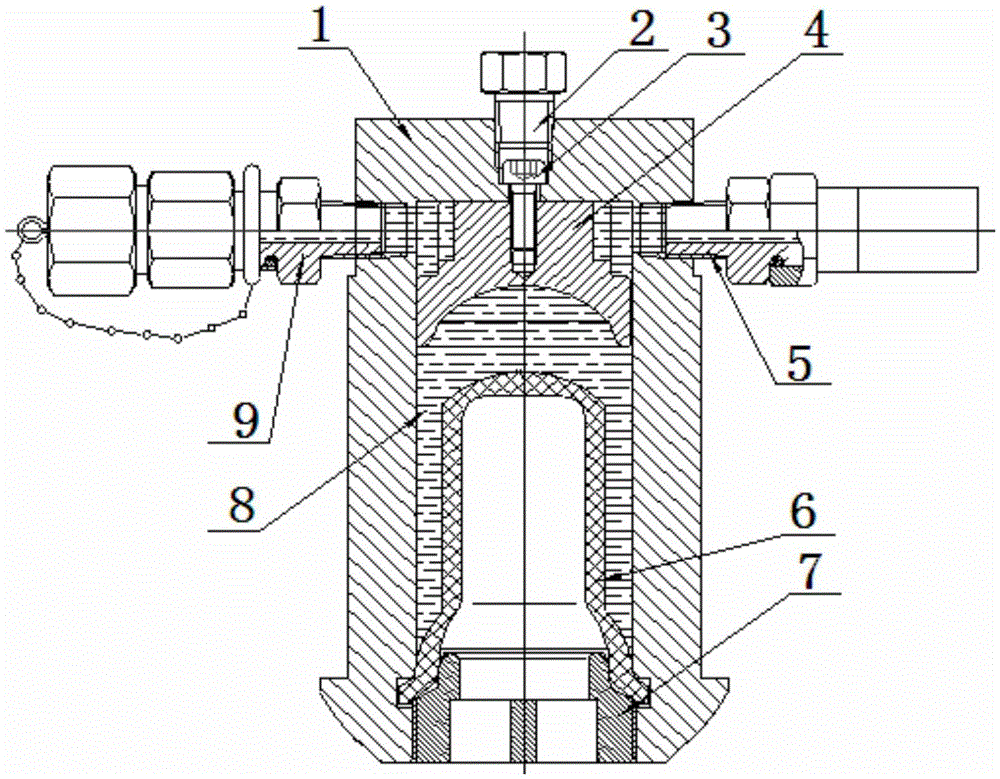

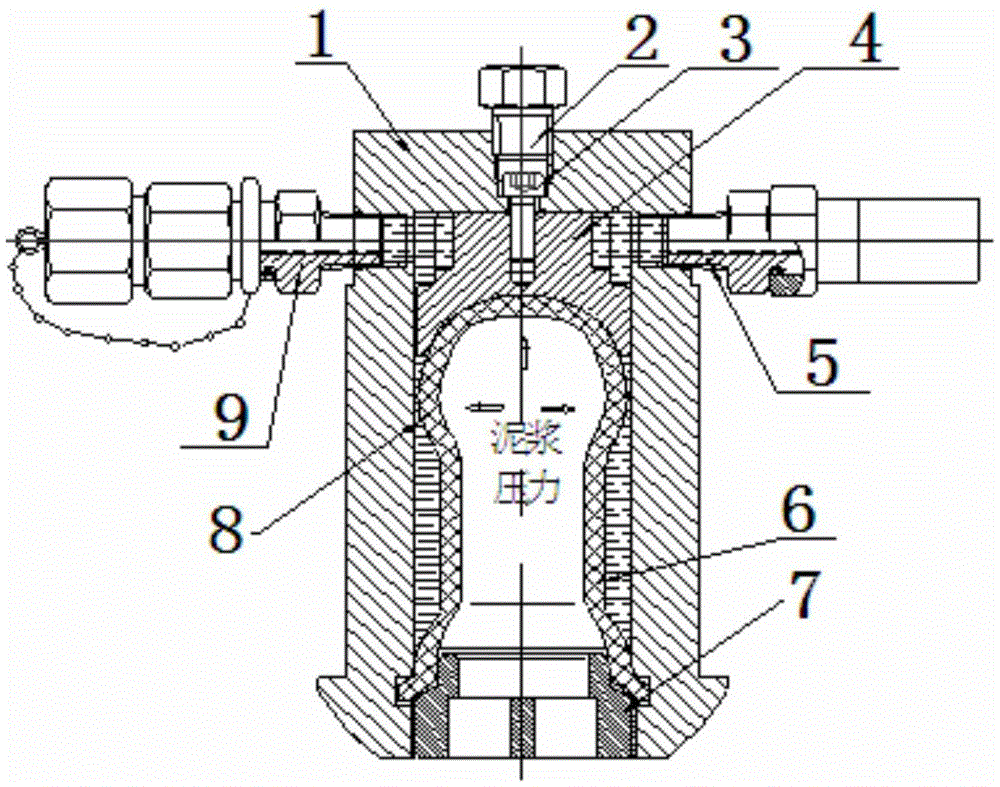

[0017] The present invention is described in detail below in conjunction with accompanying drawing:

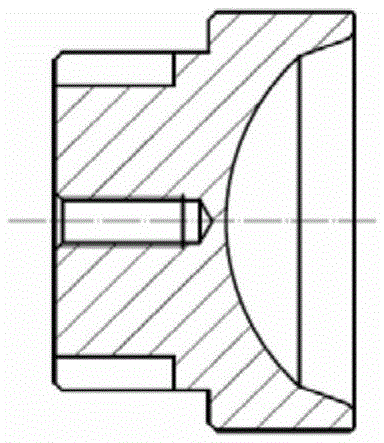

[0018] Such as figure 1 As shown, the present invention includes a cylinder bottom liner 4, a fastening screw 3 and a plug 2, and is characterized in that: the cylinder bottom liner 4 is fixed on the bottom of the cylinder body 1 by the fastening screw 3, and the raw material is tightly wound on the plug 2 The band plugs the cylinder block 1 bottom hole. Such as Figure 3a , Figure 3b As shown, one end of the cylinder liner 4 is a bowl-shaped concave curved surface, which is the same shape as the bottom of the rubber cup 6, and can support the rubber cup 6. When the rubber cup 6 expands, it is evenly stressed and is not easy to break. 4. The other end is a plane with a threaded hole, which is fastened to the bottom plate of the cylinder body 1 by bolts and will not loosen in the cylinder body 1.

[0019] The outer diameter of the cylinder liner 4 is smaller than the inne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com