A high temperature and high pressure adiabatic oxidation experiment system and method

A high-temperature, high-pressure, experimental system technology, applied in the direction of material inspection products, measuring devices, instruments, etc., can solve problems such as damage, achieve the effects of maintaining reaction temperature, ensuring safety, and improving experimental accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

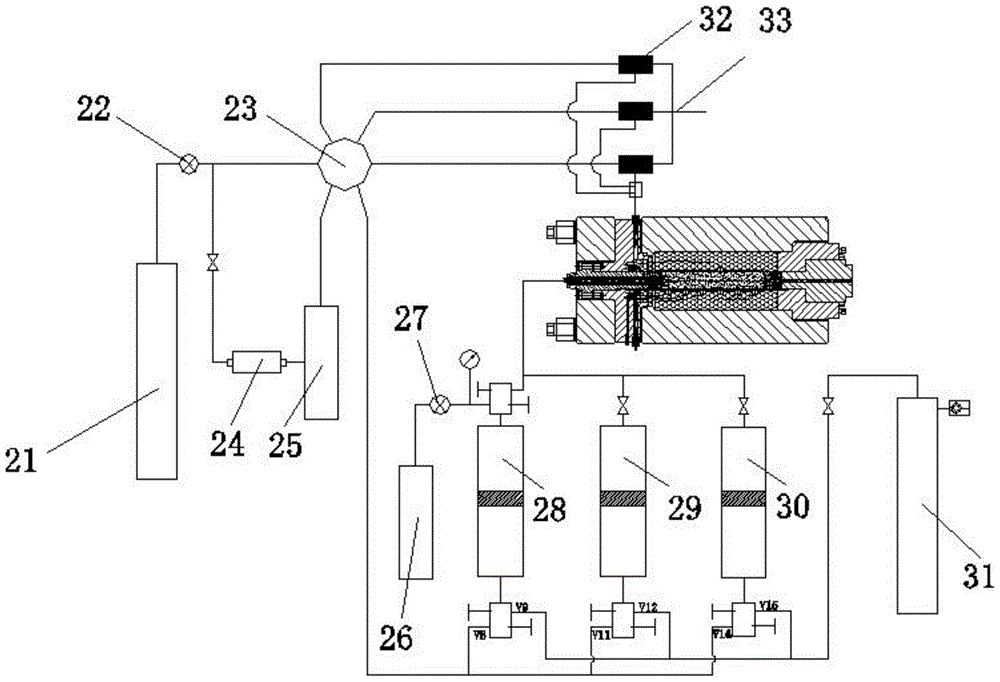

[0041] The specific experimental steps of the high temperature and high pressure adiabatic oxidation experimental system are as follows:

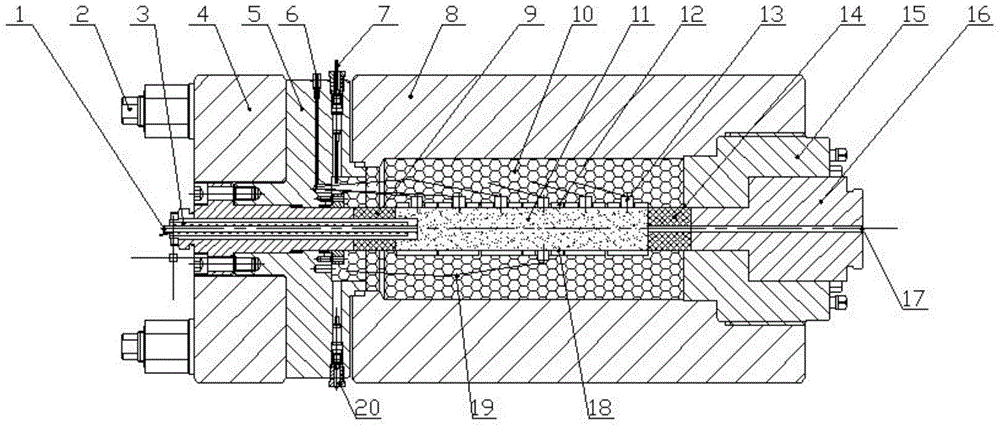

[0042] 1) Fill the experimental oil sand into the core steel sleeve 18, connect the two ends of the core steel sleeve 18 with the heat insulation layer 1 9 and the heat insulation layer 2 14, and send it into the model kettle body 8, and install the model injection ports 1 and 1 at both ends respectively. Model kettle body 8, flange 4, core steel sleeve 18, model head 5, kettle body end cover 15, kettle body head 16 and model outlet 17;

[0043] 2) The experimental container module is located in the center of the system, and the pressure tracking compensation module and the sample injection module are respectively connected to ensure the sealing of each connection position. Before use, the entire system needs to be tested for pressure, and the pressure test pressure should meet the requirements of the experiment. Pressure, not exceeding 70M...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com