Configuring method of current equalizing resistor for direct current grounding electrode

A configuration method, DC grounding technology, applied in electrical digital data processing, special data processing applications, instruments, etc., can solve problems such as step voltage exceeding the standard, lower than the allowable value, and inability to implement, and achieves strong engineering applicability and cost. Inexpensive and reliable results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The technical solution of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments:

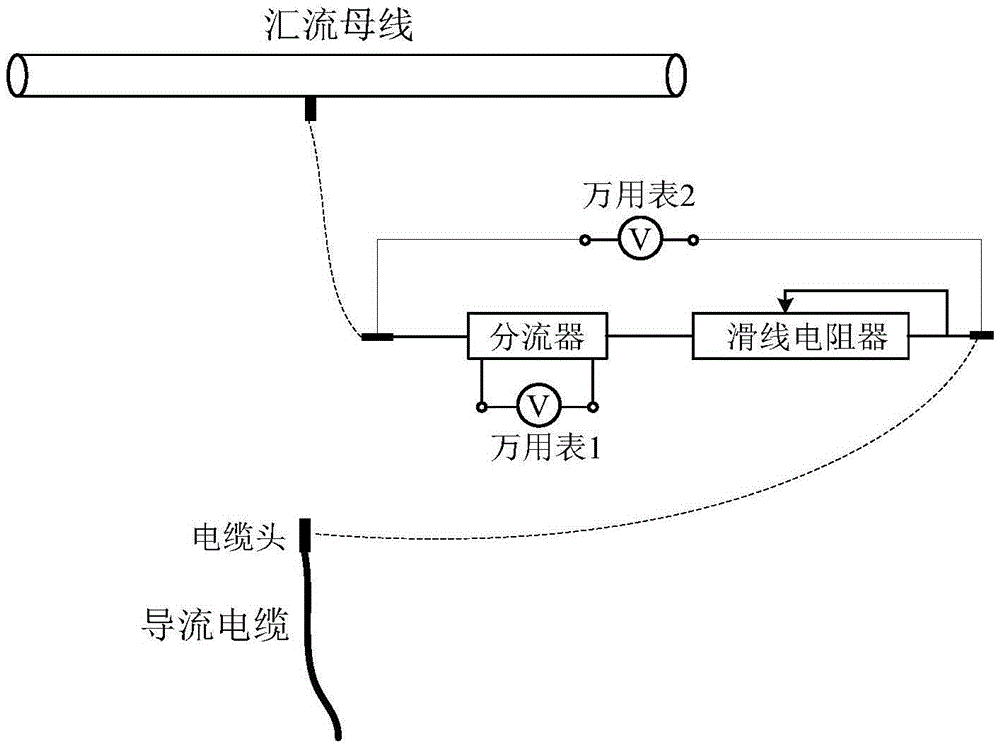

[0037] After the construction of the ground electrode is completed, the DC power supply is used for power supply, and the ground grid of the converter station, the ground electrode pole line and the ground electrode are used to form a test circuit, and a DC current of not less than 100A is injected into the ground electrode current and the current is kept constant. According to the segmentation of the design of the ground pole ring and the corresponding relationship between the guide cable and the ring section, the shunt value of each guide cable of the ground electrode, the ground resistance value of the ground electrode, the ground resistance value of each section of the pole ring, and the ring section are measured. The mutual resistance value between the segments, the step voltage coefficient of each segmen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com