Waterproof control unit and method of assembling the same

A control unit, waterproof technology, used in coupling devices, electrical components, printed circuit manufacturing, etc., can solve the problems of inability to assemble for use, deep convex and concave surfaces, difficult to form, etc., to improve waterproof performance, prevent peeling, and improve deformation. the effect of strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

[0095] (1) Detailed description of the structure

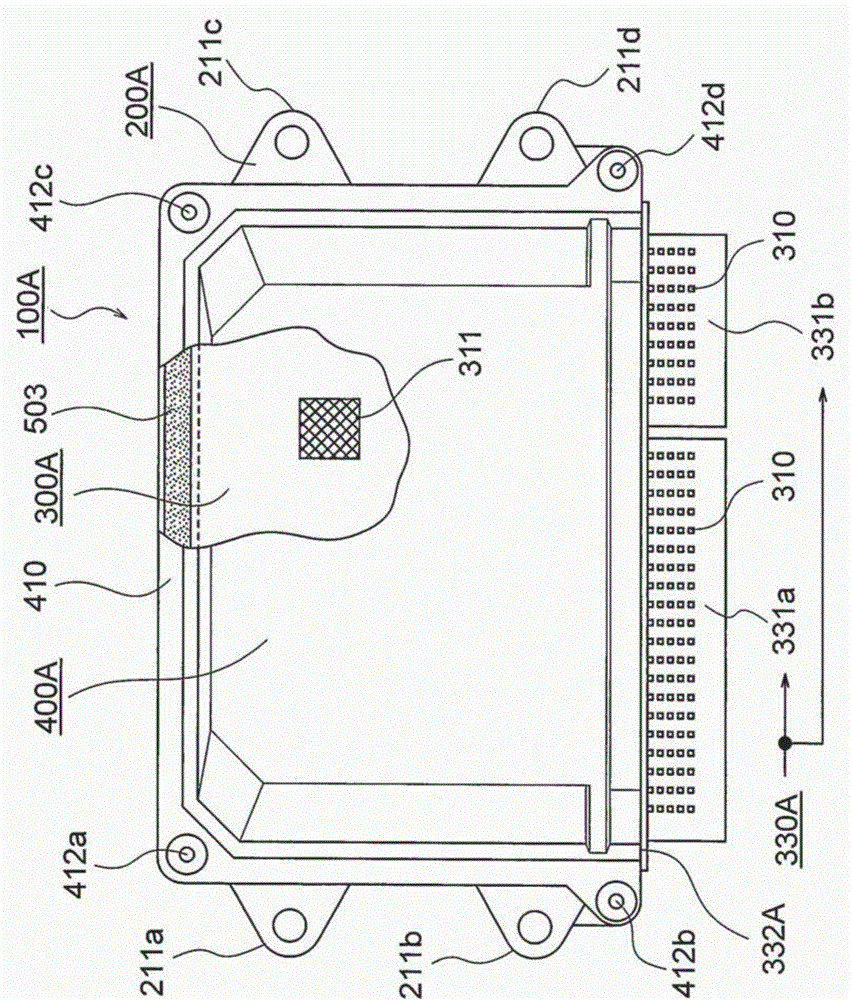

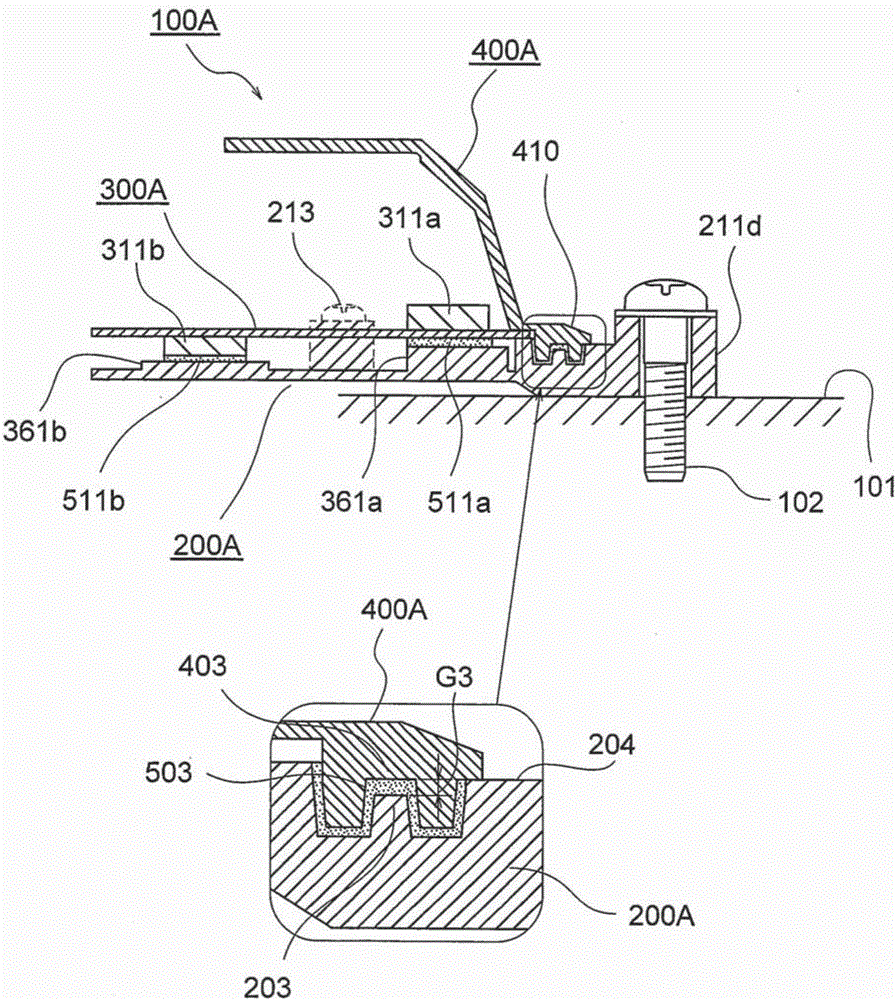

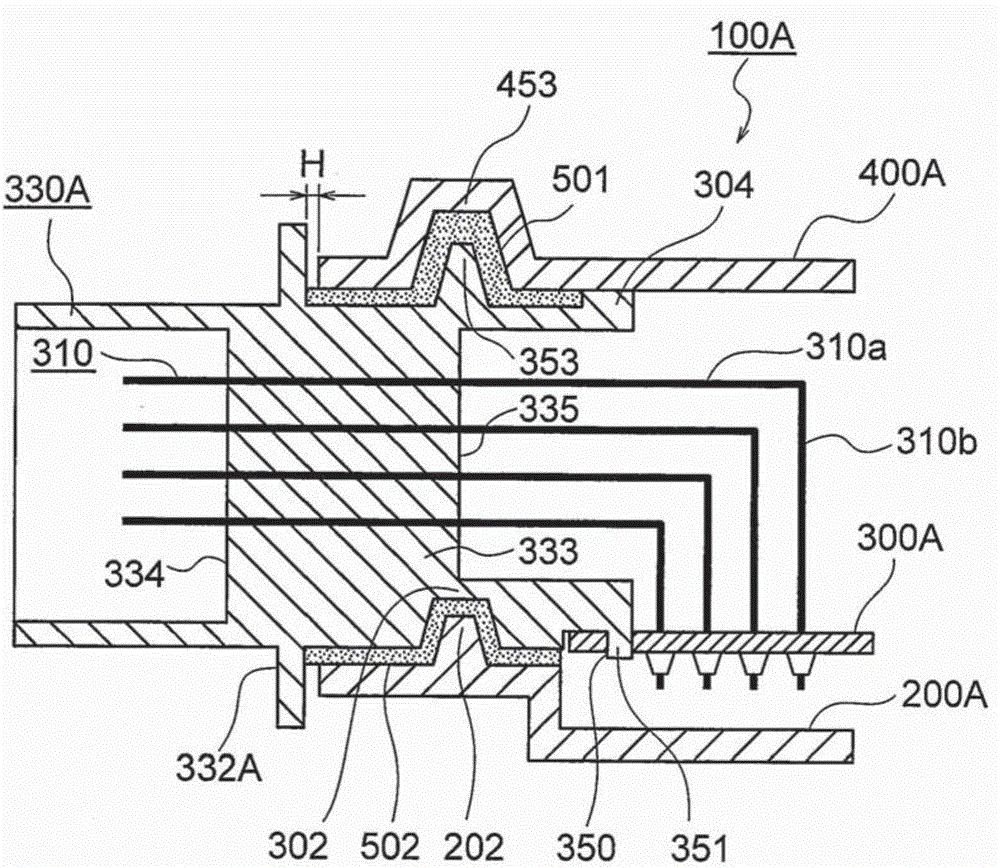

[0096] First, in order figure 1 , figure 2 , image 3 , Figure 4A ~ Figure 4C ,as well as Figure 5 , figure 1 is an external view of a waterproof control unit according to Embodiment 1 of the present invention, figure 2 yes figure 1 The installation structure diagram of the waterproof control unit, image 3 yes figure 1 A detailed cross-sectional view of the connector box, Figure 4A ~ Figure 4C yes image 3 A more detailed cross-sectional view of the connector box, Figure 5 is along Figure 4A A cross-sectional view of the connector box observed on the D-D line.

[0097] exist figure 1 Among them, the waterproof control unit 100A includes: a base 200A made of aluminum alloy die-casting having mounting feet 211a to 211d at four corners; a circuit board 300A loaded with a plurality of circuit devices 311 and heating devices 311a and 311b described later; And the resin housing 400A having edge-shaped flanges...

Embodiment approach 2

[0215] (1) Detailed description of the structure

[0216] Next, the top view of the waterproof control unit according to Embodiment 2 of the present invention is Figure 10 , Figure 10 The side partial sectional view of the waterproof control unit is Figure 11 , Figure 10 A detailed cross-sectional view of the connector box viz. Figure 12 , Figure 12 A more detailed cross-sectional view of the connector box is Figure 13A ~ Figure 13C , and will be along Figure 13A The cross-sectional view observed on the D-D line of the connector box is turned upside down and the figure is Figure 14 , with Figure 1 to Figure 5 Focusing on the differences, we will describe in detail.

[0217] In addition, the same code|symbol in each figure shows the same or corresponding part.

[0218] Figure 10 Among them, the waterproof control unit 100B includes: a base 200B made of metal plate having mounting feet 211B, 211B on the left and right; The shell 400B made of a metal plate h...

Embodiment approach 3

[0302] (1) Detailed description of the structure

[0303] Next, the rear appearance view of the waterproof control unit according to Embodiment 3 of the present invention is Figure 18 , Figure 18 The partial cross-sectional side view of the waterproof control unit is Figure 19 , Figure 18 A detailed cross-sectional view of the connector box viz. Figure 20 , Figure 18 A more detailed cross-sectional view of the connector box is Figure 21A ~ Figure 21C , with Figure 1 to Figure 5 Focusing on the differences, we will describe in detail. In addition, the same code|symbol in each figure shows the same or corresponding part.

[0304] exist Figure 18 Among them, the waterproof control unit 100C includes: a base 200C made of aluminum alloy die-casting having mounting feet 211a-211d at four corners; Figure 19 A plurality of circuit components 311 shown, a circuit board 300C of heat generating components 311a and 311b described later, and a case 400C made of a metal p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com