Drive trains for motor vehicles

A drive system and motor vehicle technology, applied in the drive system field, can solve problems such as shift extension and internal combustion engine power limitations, and achieve the effects of reducing shift time, realizing gear replacement, and improving shift quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

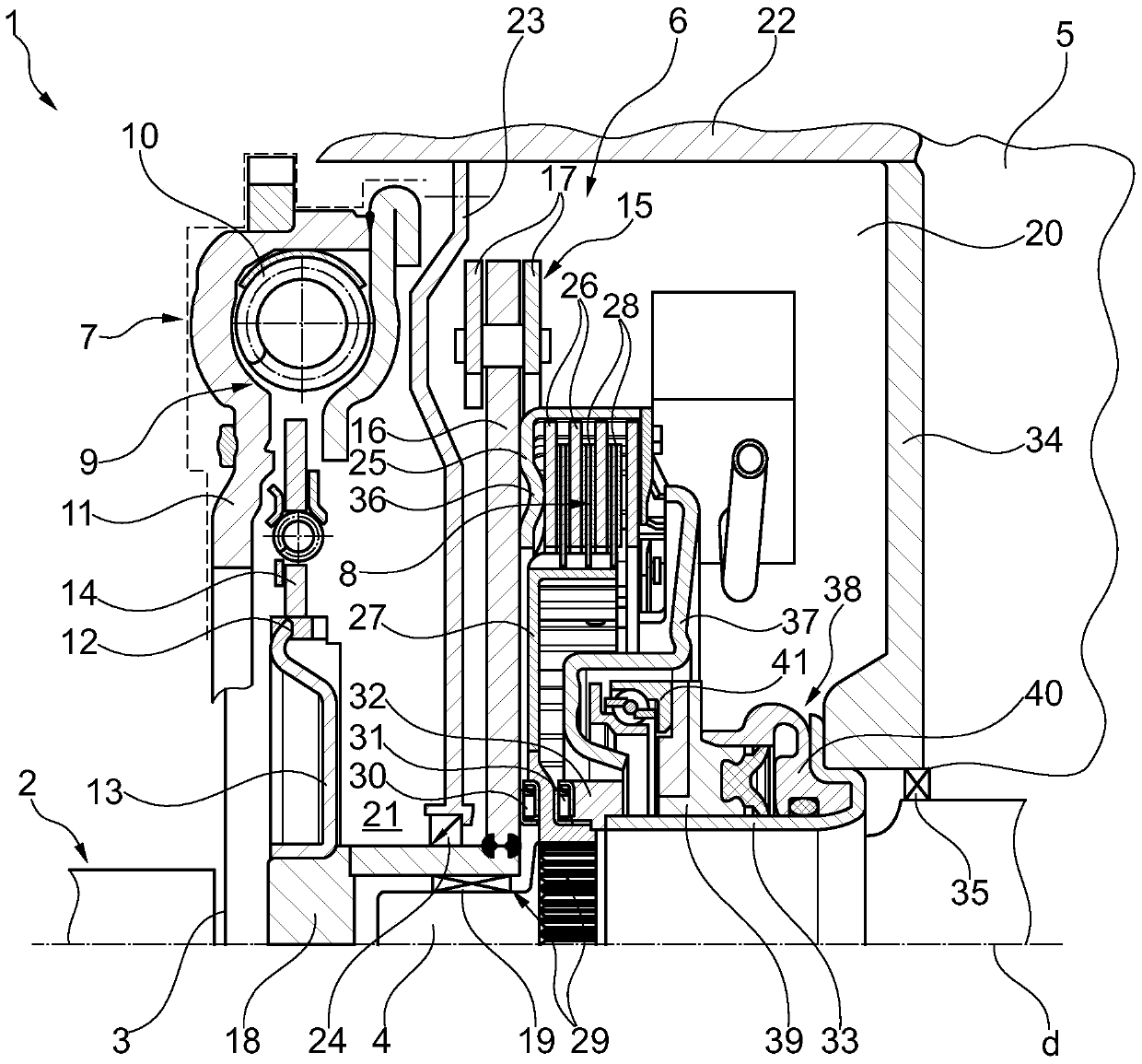

[0018] The single FIGURE schematically shows the upper half of a drive train 1 arranged around an axis of rotation d with: a merely implied internal combustion engine 2 with a crankshaft 3 ; a torque transmission device 6 arranged on the crankshaft 3 and only Between the transmission input shaft 4 of the implied automatic transmission 5 there is a torsional vibration damper 7 and a wet-running friction clutch 8 . The torsional vibration damper 7 is designed as a dual-mass flywheel 9 with an input 11 connected to the crankshaft 3 and receiving the spring arrangement 10 as primary flywheel mass, and an output 14 connected to the The transition plate 13 is connected. The secondary flywheel mass of the dual-mass flywheel 9 forms a centrifugal force pendulum 15 and a friction clutch, and the centrifugal force pendulum is formed by a flange part 16 and a pendulum mass 17 .

[0019] The input part 11 and the output part 14 can be twisted relative to each other against the action of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com