Industrial culture system of pond

A breeding system and pond technology, applied in fish farming, animal husbandry, application, etc., can solve the problems of declining quality of cultured species, low dissolved oxygen in the culture pond, and affecting the total production of culture, so as to improve the water quality and increase the concentration. Sewage discharge efficiency and the effect of reducing working hours

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be described in detail below with reference to the accompanying drawings and in combination with embodiments.

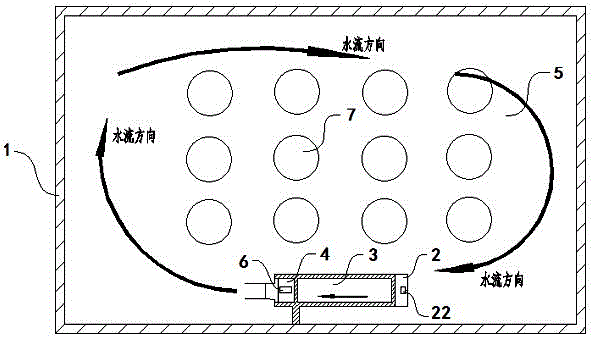

[0043] see figure 1 As shown, an industrialized pond breeding system is installed in a pond 1 and consists of a water pushing aeration unit 2 , a breeding feeding unit 3 , a sewage collecting and discharging unit 4 and an ecological purification unit 5 .

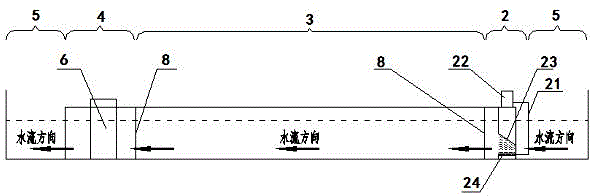

[0044] The water pushing aeration unit 2 is located at the most upstream of the whole system, and the water pushing aeration unit 2 is located at the most upstream of the whole system. A blower 22 for injecting gas into the aeration device 24, a baffle 23 for changing the direction of water flow, an air pipe 21 for connecting the blower 22 and the aeration device 24, the blower 22 is set above the water surface, the aeration device 24 is set on the bottom of the push water aeration unit 2, the air pipe 21 is connected between the blower 22 and the aeration device 24, and the baffl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com