Skin and hand disinfectant

A disinfectant, skin hand technology, applied in the direction of topical antibacterial agents, active ingredients of hydroxyl compounds, organic active ingredients, etc., can solve the problems of intractable effect, achieve the effect of fragrant smell, moisturizing effect, and improve the time of disinfection and sterilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Various raw materials are: 0.15% of polyhexamethylene biguanide, 50% of ethanol, 0.05% of emollient, 0.01% of flavoring agent, and 50% of purified water.

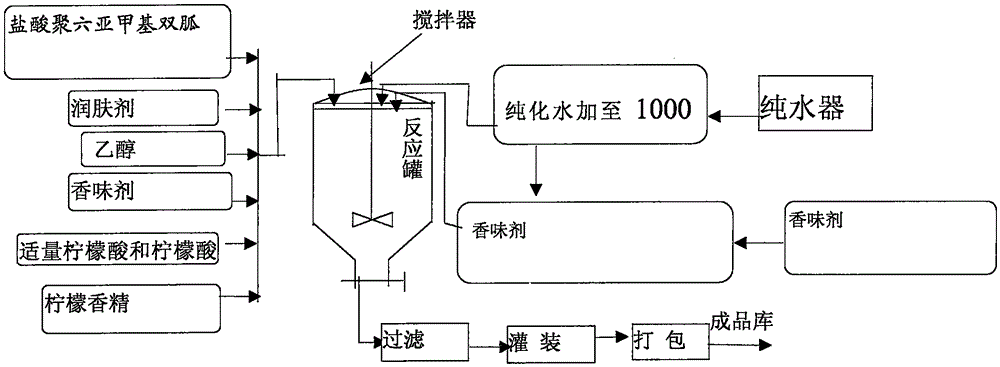

[0031] Its production method is as follows:

[0032] a. Add 600 kg of deionized water to a 1500L stainless steel reactor, then slowly add 600 kg of ethanol into the deionized water, start the reactor to stir, and mix for 1 hour at a stirring rate of 90 rpm;

[0033] b. Add 1.8 kg of polyhexamethylene biguanide weighed into the ethanol aqueous solution prepared in the reaction kettle, and stir at room temperature for 2 hours. After the polyhexamethylene biguanide is fully mixed, add 0.6 kg of moistening Skin agent and 0.12 kilograms of flavoring agents, stirred at room temperature for 3 hours;

[0034] c. finally adjust pH=4.8±1.0 with citric acid or sodium citrate;

[0035] d. Stir fully for half an hour, then filter, can, and pack into finished products;

[0036] e. Warehouse after passing the inspection.

Embodiment 2

[0038] Various raw materials are: 0.1% of polyhexamethylene biguanide, 45% of ethanol, 0.04% of emollient, 0.009% of flavoring agent, and 55% of purified water.

[0039] a. Add 660 kg of deionized water to a 1500L stainless steel reactor, then slowly add 540 kg of ethanol into the deionized water, start the reactor to stir, and mix for 1 hour at a stirring rate of 90 rpm;

[0040] b. Add 1.2 kg of polyhexamethylene biguanide weighed into the ethanol aqueous solution prepared in the reaction kettle, and stir at room temperature for 2 hours. After the polyhexamethylene biguanide is fully mixed, add 0.48 kg of moistening skin agent and 0.11 kg of flavoring agent, stirred at room temperature for 3 hours;

[0041] c. finally adjust pH=4.8±1.0 with citric acid or sodium citrate;

[0042] d. Stir fully for half an hour, then filter, can, and pack into finished products;

[0043] e. Warehouse after passing the inspection.

Embodiment 3

[0045] Various raw materials are: 0.2% of polyhexamethylene biguanide, 55% of ethanol, 0.07% of emollient, 0.011% of flavoring agent, and 45% of purified water.

[0046] a. Add 540 kg of deionized water into a 1500L stainless steel reactor, then slowly add 660 kg of ethanol into the deionized water, start the reactor to stir, and mix the materials at a stirring rate of 90 rpm for 1 hour;

[0047] b. Add 2.4 kg of polyhexamethylene biguanide weighed into the ethanol aqueous solution prepared in the reaction kettle, and stir at room temperature for 2 hours. After the polyhexamethylene biguanide is fully mixed, add 0.84 kg of moistening skin agent and 0.13 kg of flavoring agent, stirred at room temperature for 3 hours;

[0048] c. finally adjust pH=4.8±1.0 with citric acid or sodium citrate;

[0049] d. Stir fully for half an hour, then filter, can, and pack into finished products;

[0050] e. Warehouse after passing the inspection.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com