Fluid air cleaning machine

An air cleaning and liquid flow technology, applied in the field of air purification, can solve the problems of high cost, easy saturation of solid adsorption materials, and single function, and achieve the effect of large capacity and strong sterilization and disinfection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

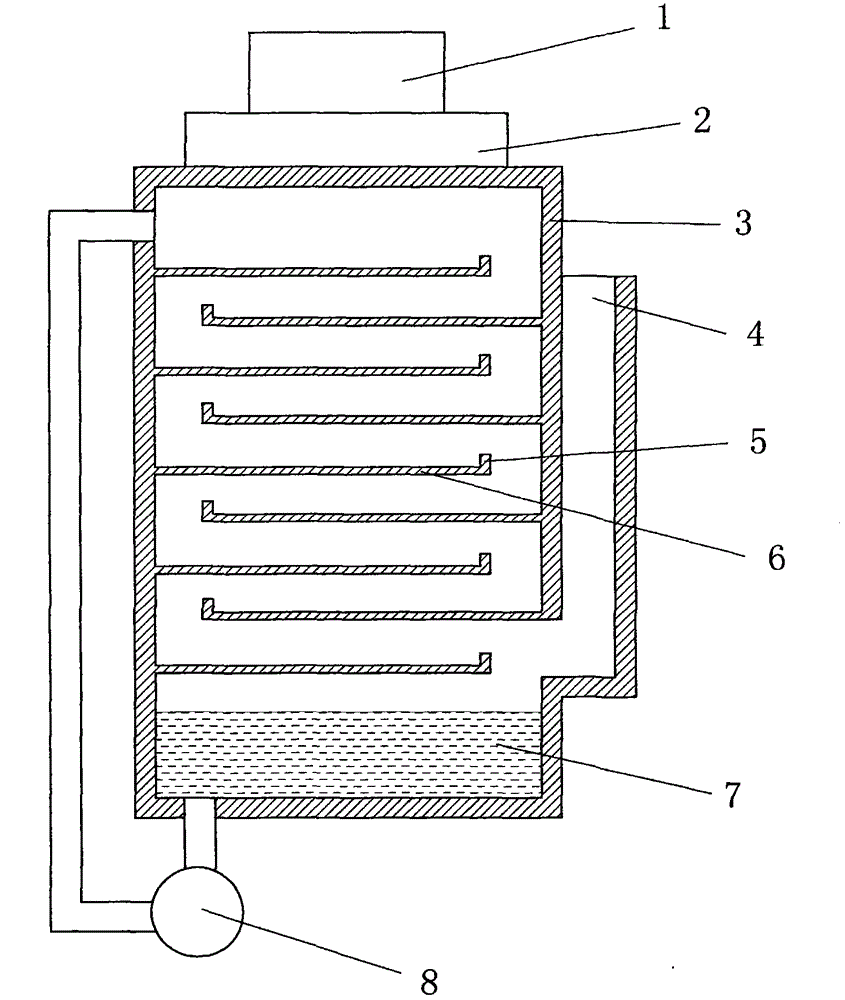

[0007] In the figure, there are air outlet (1), blower fan (2), air washing chamber (3) and water pump (8) from top to bottom. An air inlet (4) is arranged on the side of the scrubbing chamber (3). There are multiple layers of staggered water baffles (6) in the gas washing chamber (3), forming a narrow and long water flow channel, and increasing the contact surface between liquid and gas. The end of the water retaining plate (6) protrudes upwards to form a water retaining wall (5), and the upper edge of the water retaining wall (5) is tooth-shaped, so that when the water flows down from each layer of water retaining plate, it is not a whole water curtain, but several The linear flow is beneficial to the passage of gas. There is a cleaning solution (7) at the bottom of the scrubber (3), the water inlet of the water pump (8) is connected to the bottom of the scrubber (3), and the water outlet is connected to the top of the scrubber (3).

[0008] When working, start the water pu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com