A kind of method that ammonium fluoride waste water prepares phosphate pulp desulfurizer

An ammonium fluoride and phosphate slurry technology, which is applied in chemical instruments and methods, separation methods, gas treatment and other directions, can solve the problems of unstable sulfur dioxide absorption efficiency, etc., and achieves long desulfurization duration, simple process facilities and high desulfurization efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

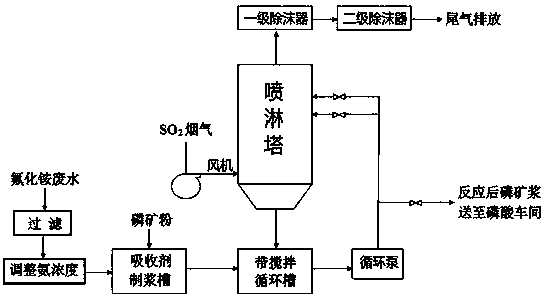

Image

Examples

Embodiment example 1

[0018] The method for preparing phosphate pulp desulfurizer from ammonium fluoride wastewater described in this implementation case includes necessary steps such as filtration of ammonium fluoride wastewater, adjustment of ammonia concentration, grinding of phosphate rock, and pulping. This case has been successfully applied to a phosphorus chemical production in Yiliang, Yunnan enterprise. The ammonium fluoride wastewater contains 0.5-0.8% ammonia, and the solid matter in the wastewater is removed by precipitation, and the obtained filtrate is stored for later use; the phosphate rock is ground to 150 mesh, and 85% of the material is sieved; the stored ammonia-containing filtrate is prepared for solid content It is a 50% phosphate slurry desulfurizer, and the pH value of the slurry is about 8.3. The diameter of the absorption tower is 3.5m, the height is 14m; the volume of flue gas to be treated is 35000m 3 / h, the concentration of sulfur dioxide is 1800~2000mg / m 3 , the oxy...

Embodiment example 2

[0020] The steps of preparing phosphate pulp desulfurizer from ammonium fluoride wastewater described in this implementation case are exactly the same as in Example 1. This implementation case is applied to a company in Yunnan with 3000Nm 3 / h Sulfuric acid tail gas treatment pilot project. The absorption tower has a diameter of 1.2m and a height of 10m. The sulfur dioxide concentration in the sulfuric acid tail gas to be treated is 600-800mg / m 3 , the oxygen content is 4.8%; the liquid-gas ratio in the absorption process is 5L / m 3 , the superficial gas velocity is 1.5m / s. The phosphate rock pulp used is ground to 200 mesh, and 85% of the material is sieved; the ammonium fluoride wastewater used contains 0.6-1.0% ammonia, and after the solid matter in the wastewater is removed by precipitation, the ammonia concentration in the filtrate is adjusted to 4.0% , and use this stock solution to prepare a phosphate rock slurry absorbent with a solid content of 40%, and the pH value...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com