An annular single-sided coated steel strip tooling

A steel strip, single-sided technology, applied in the field of ring-shaped single-sided coated steel strip tooling, can solve the problems of no paint adhesion, no coating peeling, damage to production equipment, etc. cost saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

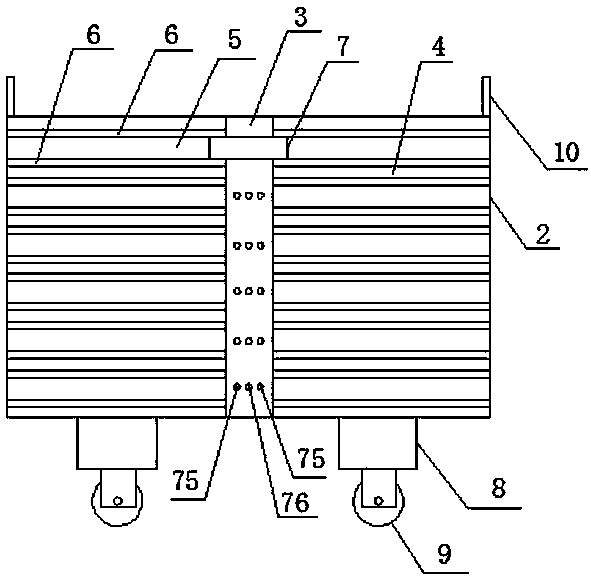

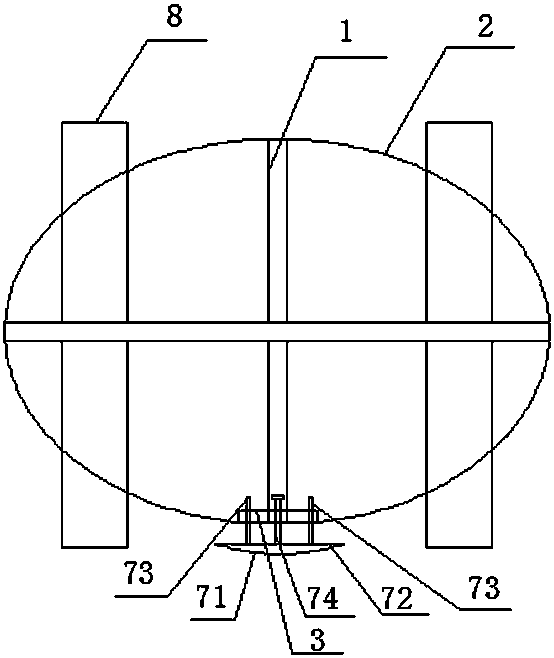

[0016] Such as figure 1 with figure 2 An annular single-sided coated steel strip frock is shown, including an intermediate bracket 1 and an elliptical ring plate 2, the seams of the elliptical ring plate 2 are connected by a connecting block 3, and the outer wall of the elliptical ring plate 2 is along the elliptical ring plate 2 There are several steel belt support units in the circumferential direction, and a partition 4 is arranged between two adjacent steel belt support units. Each steel belt support unit includes a steel belt support boss 5 with the same width as the steel belt and a There are grooves 6 on the upper and lower edges of the propping boss 5, and a steel strip tensioning mechanism 7 is provided on the connecting block 3 at the lateral position of each steel strip propping up the boss 5.

[0017] Steel belt tensioning mechanism 7 comprises arc brace 71, cross bar 72, positioning post 73 and adjusting bolt 74, and cross bar 72 is connected at the two ends of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com