Processing method of composite copper alloy plunger pump cylinder body

A processing method and copper alloy technology, applied in the field of plunger pump manufacturing, can solve problems such as low pass rate, low production efficiency, and large safety hazards, and achieve the effect of improving performance and service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

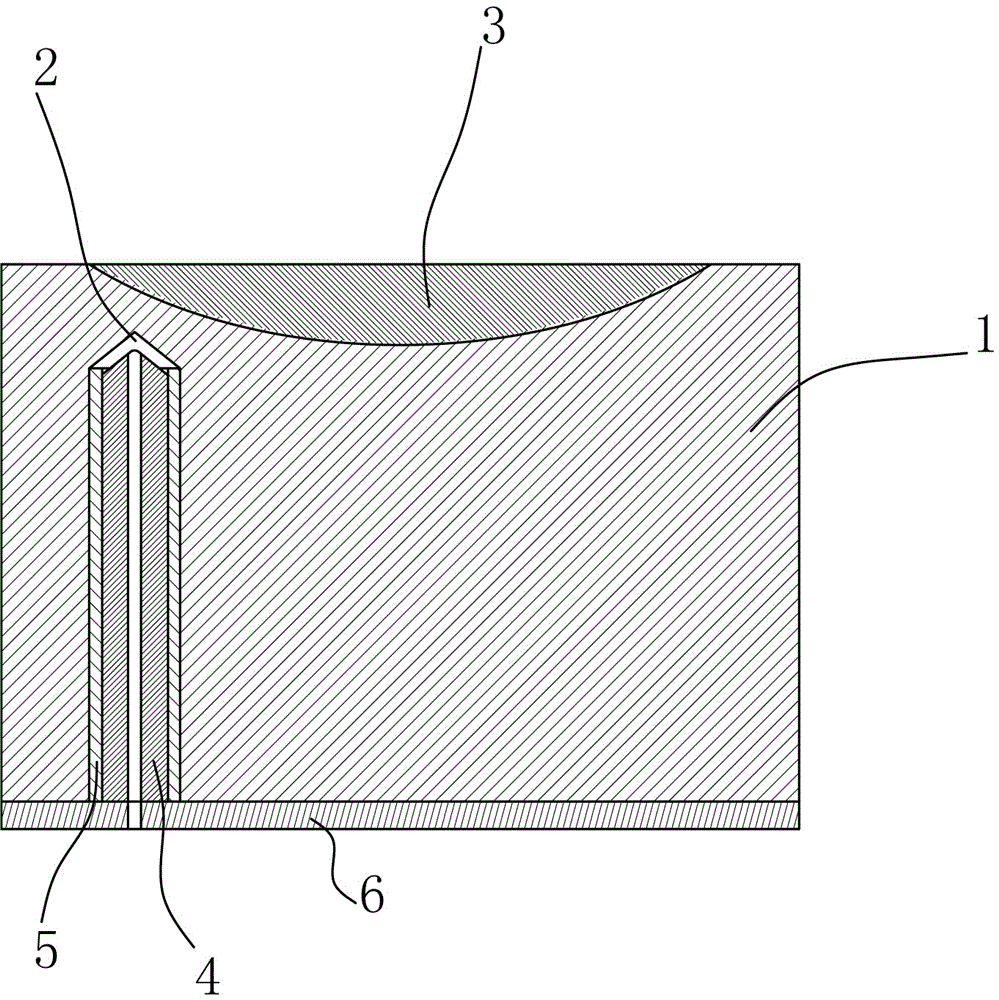

[0012] The specific implementation manner of the present invention will be described in detail below in conjunction with the accompanying drawings. Such as figure 1 As shown, a plunger pump cylinder of a composite copper alloy, the cylinder is processed from a blank 1, the top center of the blank 1 has a spherical concave surface 3, and a circle of columns is arranged inside the blank 1 Shaped cylinder hole 3, the cylinder hole 2 is provided with a copper sleeve 5, the copper sleeve 5 is set on the mandrel 4, the top of the copper sleeve 5 is lower than the top of the mandrel 4, the A through hole is opened in the center of the mandrel 4 , and a sealing plate 6 is installed on the lower end of the blank 1 . The sealing plate 6 is provided with a vent hole communicating with the through hole on the mandrel 4 .

[0013] During production, the first step is to clean the casting surface of the blank 1, and then apply a metal activator to the casting surface of the steel substrate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com