TM mode dielectric filter

A dielectric filter and filter technology, applied in the field of communication, can solve problems such as short service life, achieve the effect of improving service life and performance, and reducing thermal expansion coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

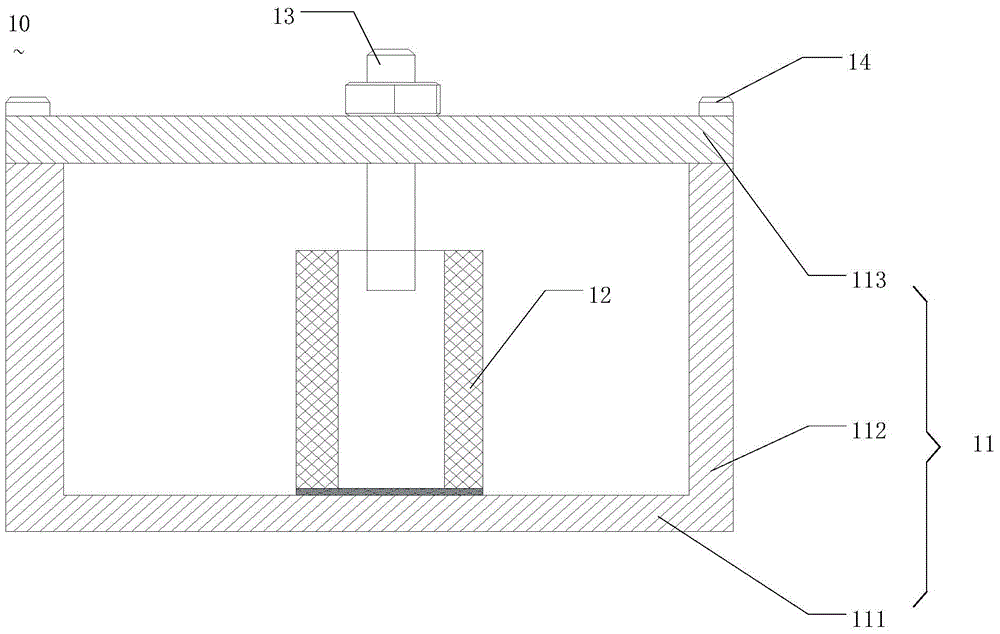

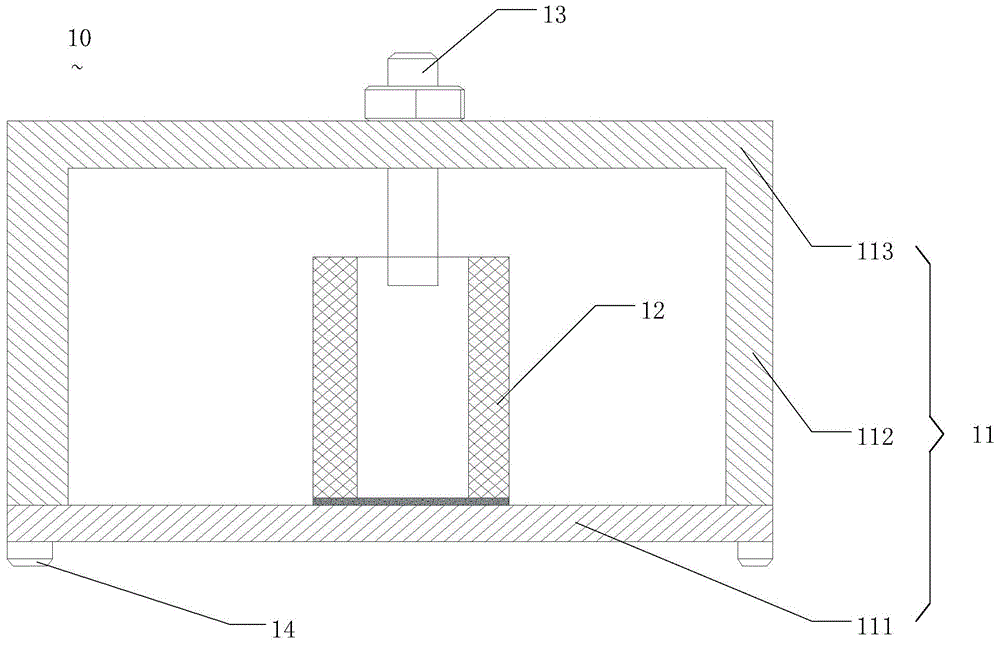

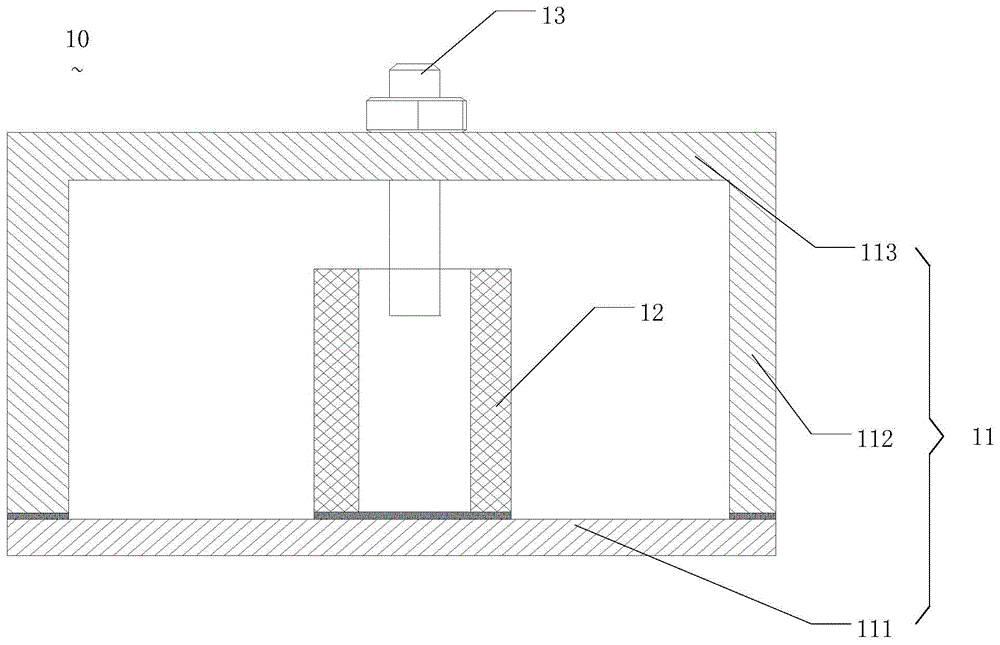

Image

Examples

Embodiment 1

[0030] The alloy material is formed by liquid extrusion casting of various raw materials under high temperature conditions. The components of the alloy material and the weight percentages of each component are: 20.0% silicon, 2.0% magnesium, 1.0% iron, manganese 1.0%, impurity 1.0%, aluminum 75.0%. Its coefficient of thermal expansion is 18.5×10 -6 / ℃, the thermal conductivity is 170.8W / m·K, and the yield strength is 160.2MPa.

Embodiment 2

[0032] The alloy material is formed by liquid extrusion casting of various raw materials under high temperature conditions. The components of the alloy material and the weight percentages of each component are: silicon 27%; magnesium 0.5%; iron 0.6%; manganese 0.5%; aluminum 71.4%. Its coefficient of thermal expansion is 16.0×10 -6 / ℃, the thermal conductivity is 150.8W / m·K, and the yield strength is 157.5MPa.

Embodiment 3

[0034] The alloy material is formed by liquid extrusion casting of various raw materials under high temperature conditions. The components of the aluminum-silicon alloy and the weight percentages of each component are: 32% silicon; 0.35% magnesium; 0.3% iron; Manganese 0.35%; Aluminum 67%. Its coefficient of thermal expansion is 14.8×10 -6 / ℃, the thermal conductivity is 147W / m·K, and the yield strength is 152.5MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thermal expansion coefficient | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com