Cleaning machine

A cleaning machine and motor assembly technology, applied in the field of cleaning machines, can solve the problems affecting the heat dissipation effect of the motor, affecting the performance and service life of the cleaning machine, etc., and achieve the effect of avoiding mutual interference of heat dissipation and improving performance and service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

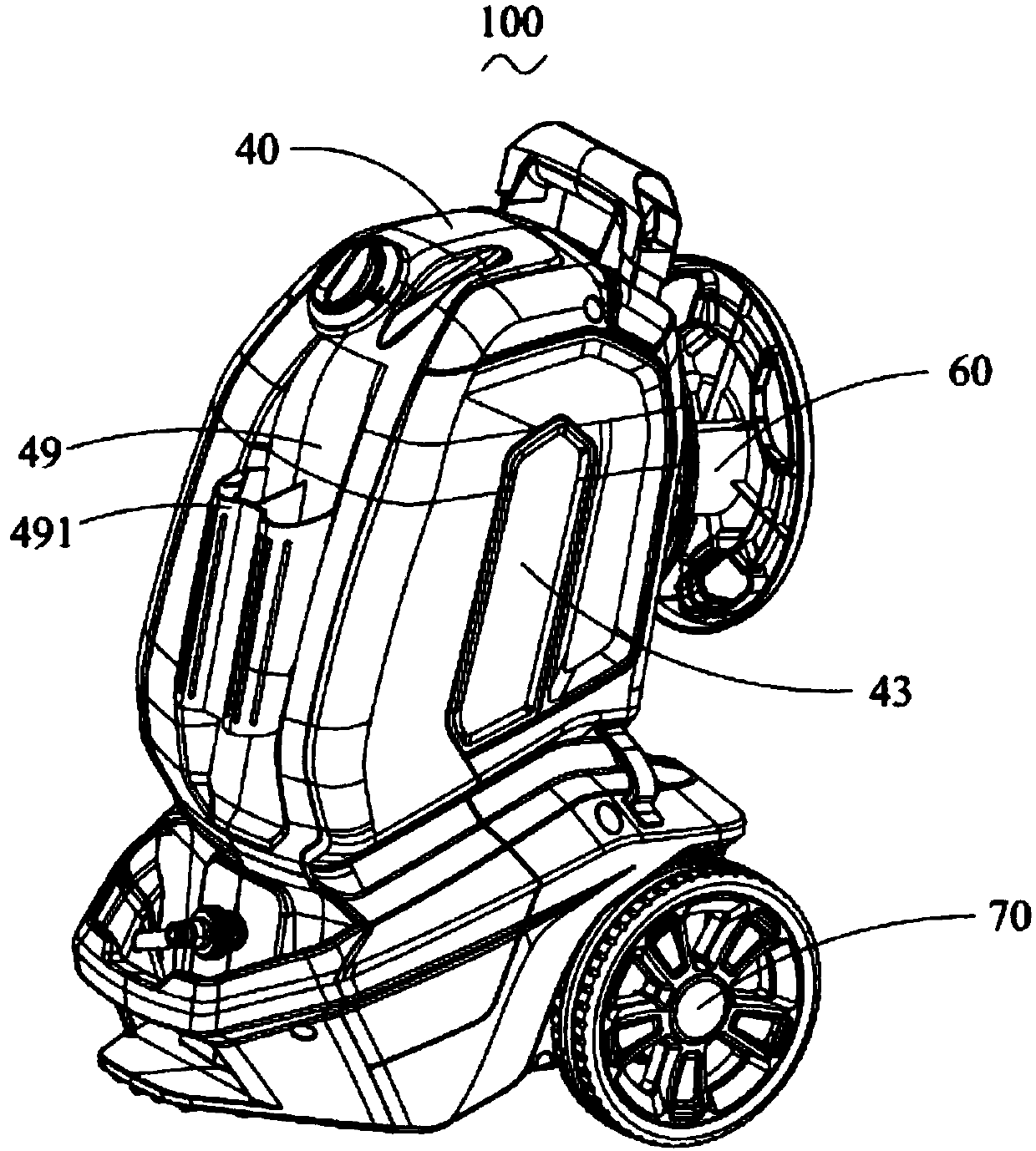

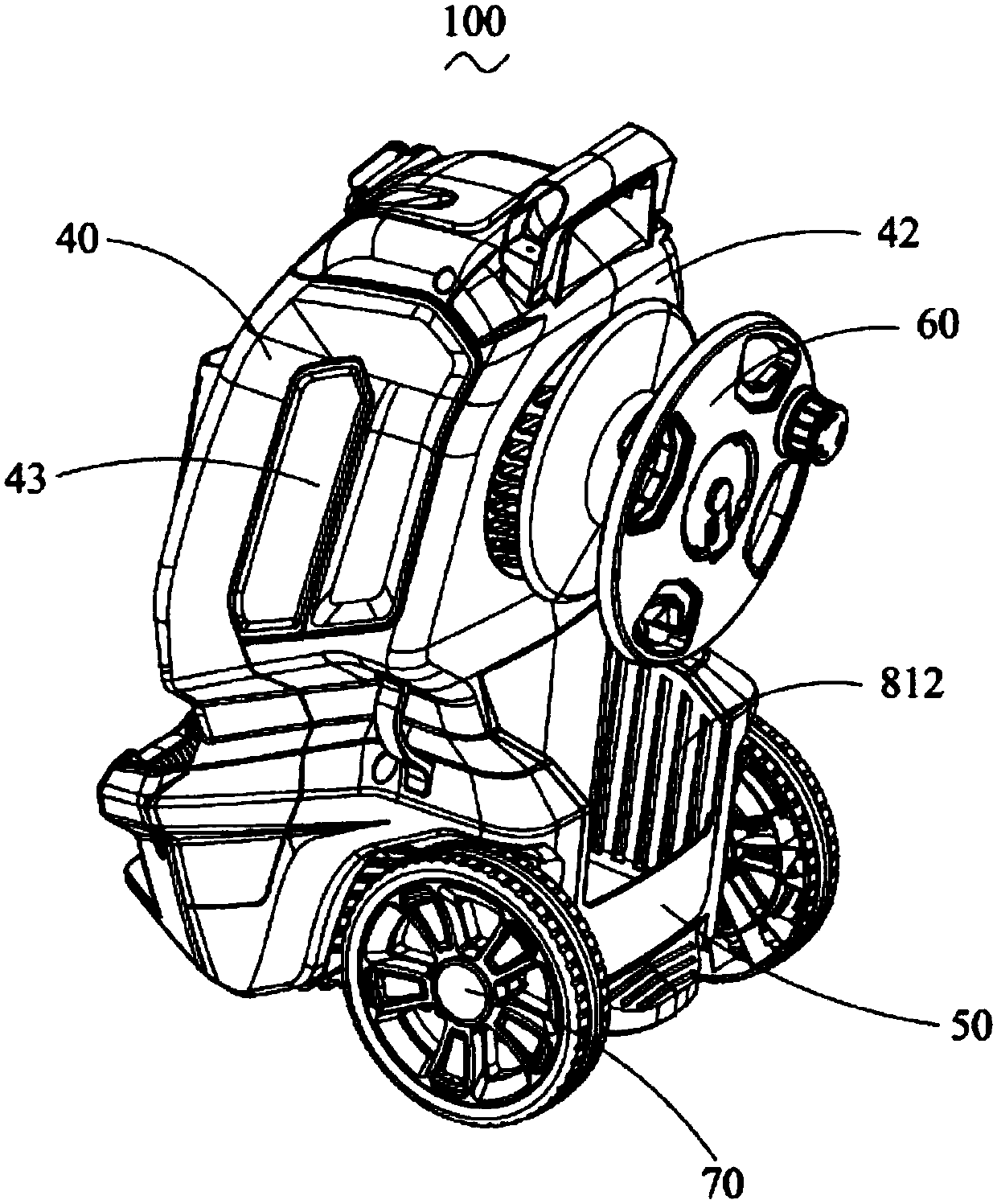

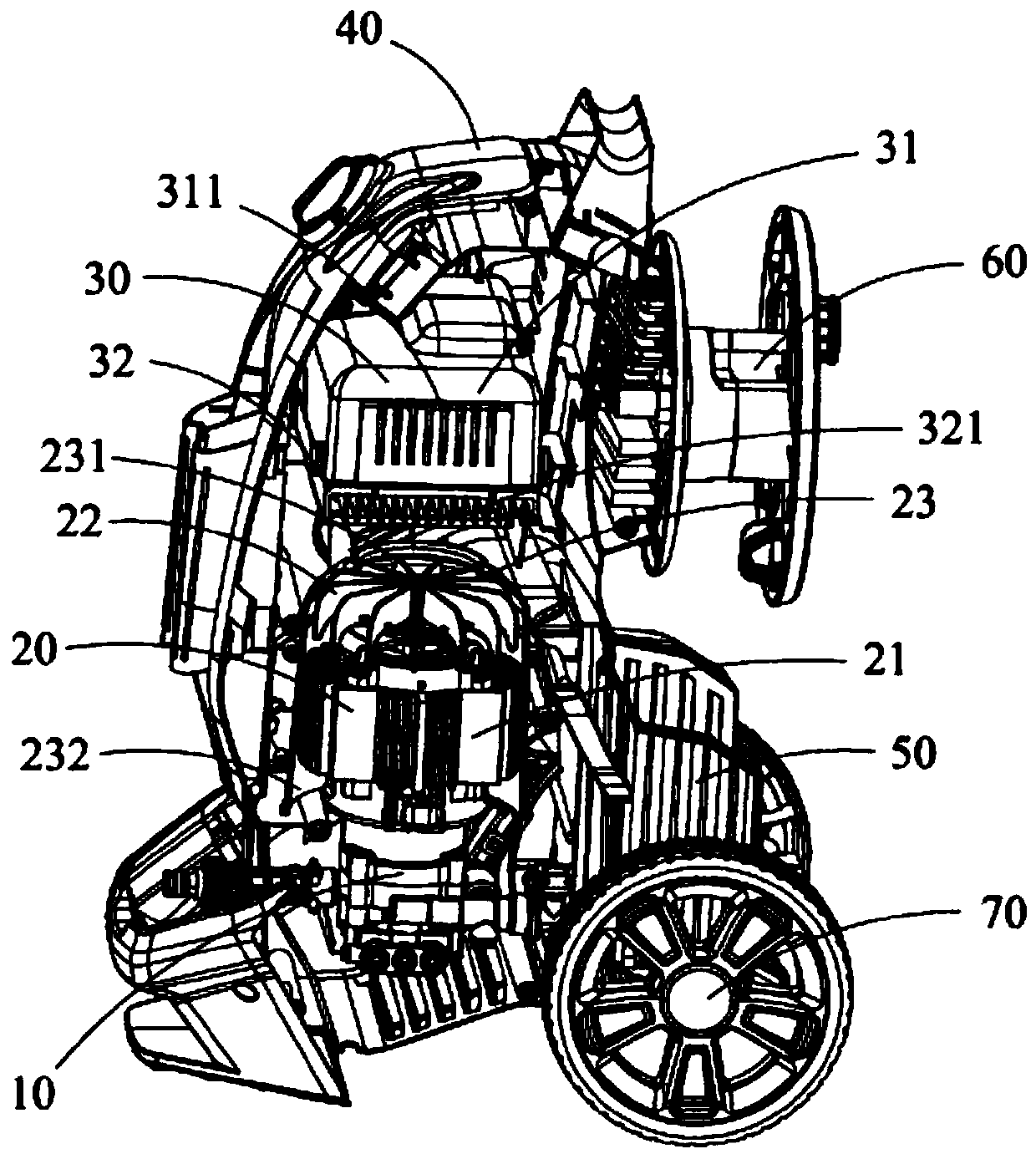

[0022] see figure 1 , figure 2 as well as image 3 As shown, the washing machine 100 of the present invention includes a high-pressure pump 10, a motor assembly 20 matched with the high-pressure pump 10, a control assembly 30 for controlling the motor assembly 20, accommodating the high-pressure pump 10, the motor assembly 20 and the The housing 40 of the control assembly 30 , the accessory pocket 50 , the hose reel 60 and the rollers 70 installed on the housing 40 .

[0023] see image 3 As shown, the high-pressure pump 10 is used to pressurize the liquid flowing through the high-pressure pump 10 . The motor assembly 20 includes a motor 21 for driving the high-pressure pump 10 , a fan blade 22 installed at the tail of the motor 21 , and a wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com