Intelligent electric spindle control implementation method

An implementation method, the technology of the electric spindle, is applied in the direction of manufacturing tools, metal processing mechanical parts, measuring/indicating equipment, etc., and can solve the problems of running speed, dynamic adjustment of load-bearing spindle rigidity, signal output of no running state parameters and intelligent adjustment functions, The motorized spindle has no running state parameter detection sensor and control method and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] In order to more fully explain the implementation of the present invention, implementation examples of the present invention are provided. These implementation examples are only illustrations of the present invention, and do not limit the scope of the present invention.

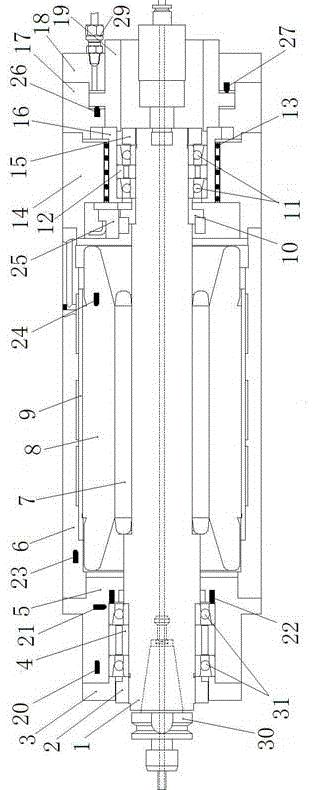

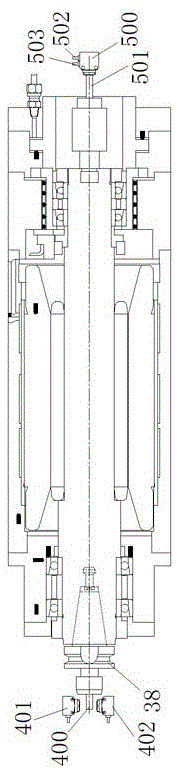

[0014] Firstly, the electric spindle of the present invention is introduced in detail, and the accompanying drawing is a schematic diagram of the electric spindle of the present invention. In the drawings, each mark is: 1: rotary shaft; 2: front nut; 3: front cover; 4: front bearing spacer ring; 5 : front bearing seat; 6: jacket; 7: driving rotor; 8: driving stator; 9: stator water jacket; 10: rotary encoder induction wheel assembly; 11: rear bearing; 12: rear bearing isolation ring; 13: bearing slide 14: Rear bearing seat support seat; 15: Rear nut; 16: Rear bearing seat; 17: Pressure servo seat; 18: Pressure servo cover; 19: Pressure servo actuator; 20: Vibration sensor; 21: Temperature sensor 1 ;22...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com