Full-automatic plate installation manipulator device

A manipulator, fully automatic technology, used in manipulators, program-controlled manipulators, chucks, etc., can solve the problems of high use cost of robot arms, not widely adopted, and inability to be realized by ordinary robots, so as to improve production and installation efficiency and structure. Simple, easy-to-install effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

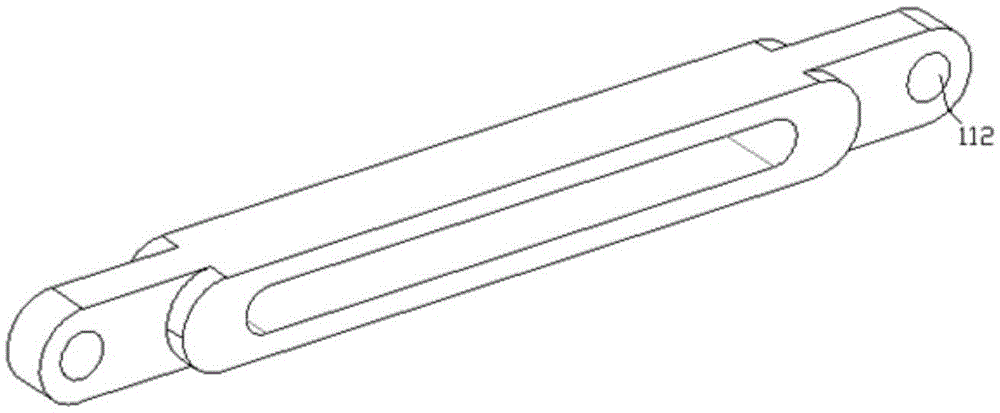

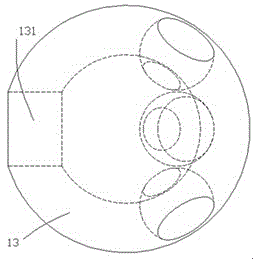

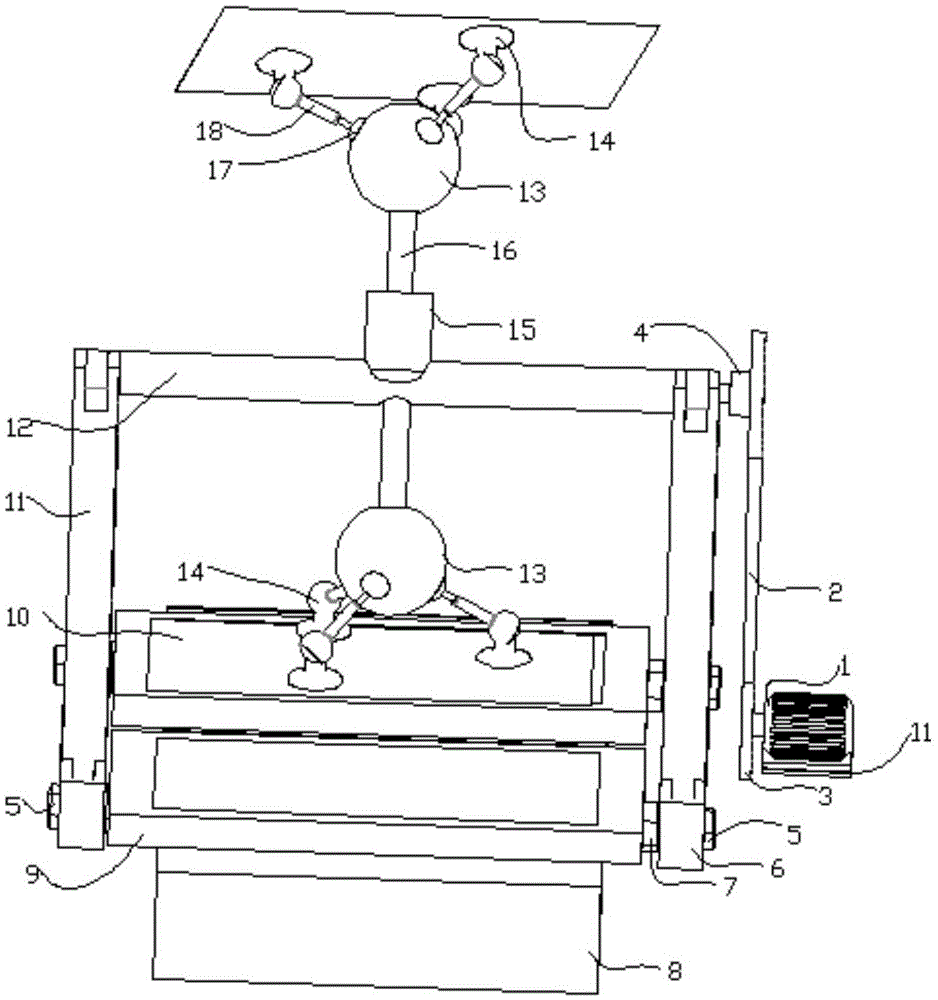

[0024] The structure diagram of the present invention is as figure 1 , 2 , 3, and 4, below will use glass as an example for the plate-shaped material to describe the structural characteristics of the present invention in detail, but the actual application scope of the present invention is not limited to this.

[0025] The fully automatic sheet material installation manipulator device of the present invention includes a gantry support, a driving device, a manipulator clamping device and a sheet material conveying device 8, wherein the manipulator clamping device is installed on the gantry support, and the drive device is connected to the manipulator clamping device , the driving device drives the gripping device of the manipulator to move, the sheet material conveying device 8 is installed under the gantry support, and the manipulator clamping device can grab the sheet material 10 conveyed by the sheet material conveying device 8 .

[0026] In this embodiment, the sheet materi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com