Glass fiber-reinforced plastic high-strength composite strengthening rib and production technology thereof

A technology of glass fiber reinforced plastics and reinforcing ribs, applied in artificial islands, water conservancy projects, infrastructure engineering, etc., can solve the problems of poor bonding between steel bars and resin materials, non-recoverable, easy to rust, etc., to prevent theft of well covers and strong integrity , good toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

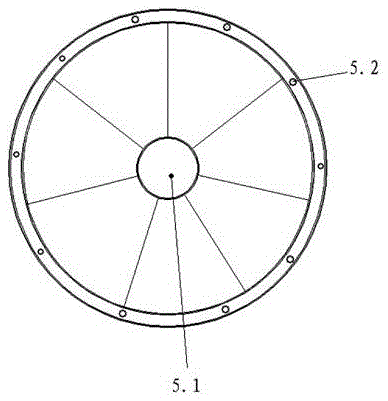

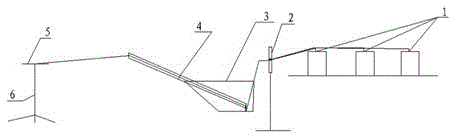

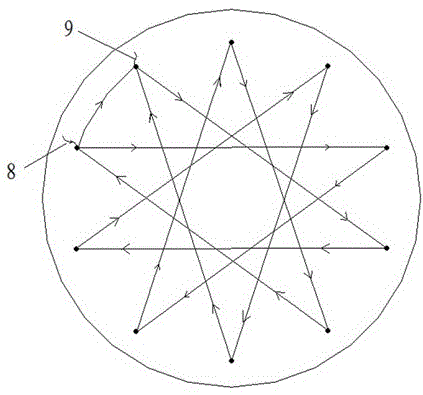

[0023] A high-strength composite reinforcement made of glass fiber reinforced plastics, in which glass fibers are wound at the same center to form multiple interlaced five-pointed star structures, and the vertices of all five-pointed star structures are located on the same circumference; the angle between adjacent five-pointed star structures is 18 Spend. The glass fiber is glass fiber uniformly impregnated with a resin adhesive, and the resin adhesive is mixed with 0.1 weight part of unsaturated polyester resin, 0.005 weight part of curing agent and 0.005 weight part of accelerator.

Embodiment 2

[0025] A high-strength composite reinforcement made of glass fiber reinforced plastics, in which glass fibers are wound at the same center to form multiple interlaced five-pointed star structures, and the vertices of all five-pointed star structures are located on the same circumference; the angle between adjacent five-pointed star structures is 36° Spend. The glass fiber is a glass fiber uniformly impregnated with a resin adhesive, and the resin adhesive is mixed with 0.3 parts by weight of unsaturated polyester resin, 0.01 parts by weight of a curing agent and 0.01 parts by weight of an accelerator.

Embodiment 3

[0027] A high-strength composite reinforcement made of glass fiber reinforced plastics, in which glass fibers are wound at the same center to form multiple interlaced five-pointed star structures, and the vertices of all five-pointed star structures are located on the same circumference; the angle between adjacent five-pointed star structures is 36° Spend. The glass fiber is a glass fiber uniformly impregnated with a resin adhesive, and the resin adhesive is mixed with 0.5 parts by weight of unsaturated polyester resin, 0.02 parts by weight of a curing agent and 0.02 parts by weight of an accelerator.

[0028] The glass fibers of Examples 1-3 are twisted into a rope-like structure from a plurality of grade E non-alkali untwisted glass fibers, the curing agent is cyclohexanone peroxide; the accelerator is cobalt naphthenate. The unsaturated polyester resin can choose HR-8309 heat-resistant unsaturated polyester resin produced by Changzhou Huarun Composite Materials Co., Ltd.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com