Buffer brake structure of slender object mark printing machine and complete printing control method

A buffer braking and marking machine technology, applied in printing, printing machines, rotary printing machines, etc., can solve the problems of uncontrollable number of times of characters, easy damage of the brake arm 11, delay in production, etc., and meet the speed requirements , Ensure braking accuracy and reduce personnel costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, but they are not used to limit the scope of the present invention.

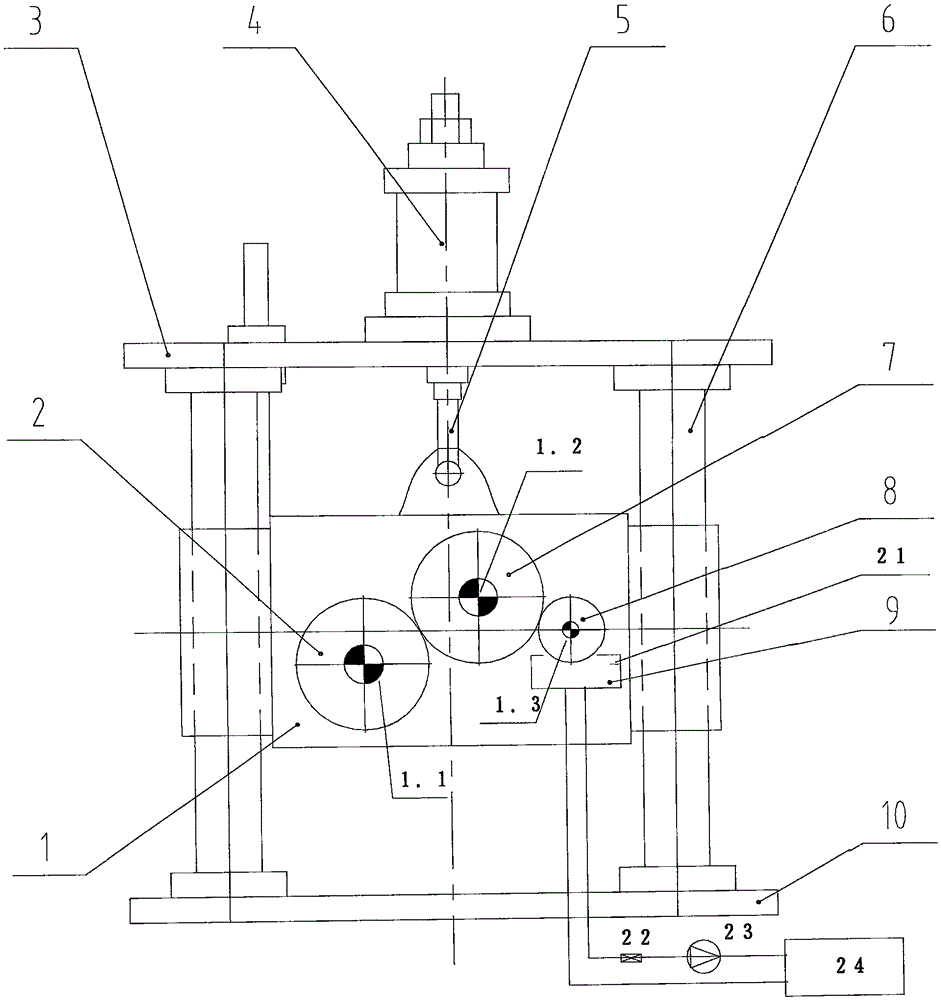

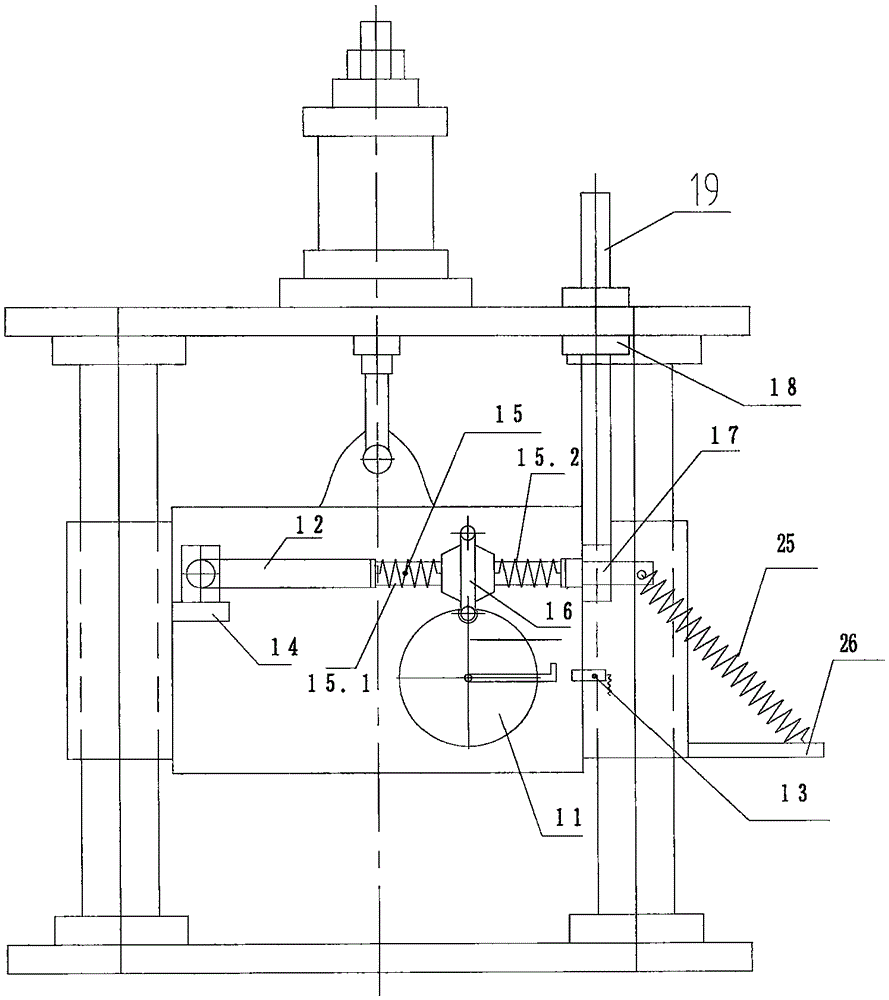

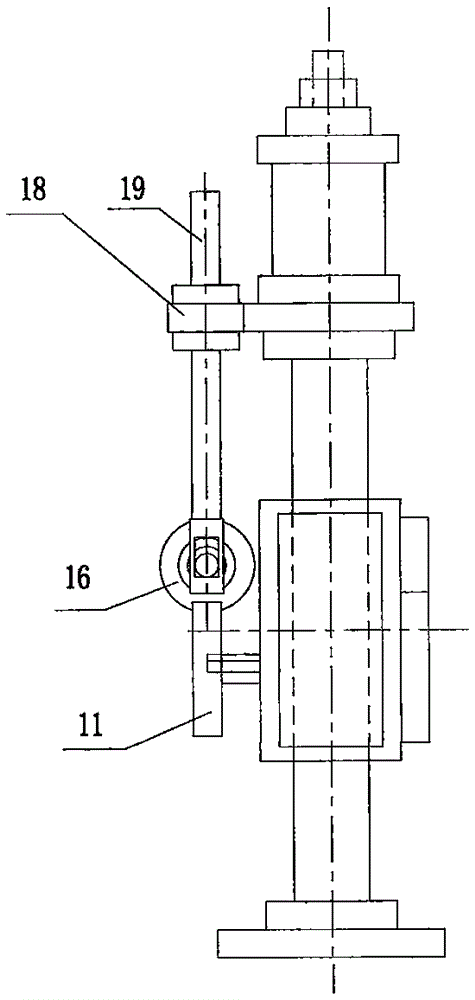

[0040] As shown in the figure, a marking machine for elongated articles includes a marking machine box 1, an upper frame plate 3, a lifting cylinder 4, a lifting arm 5, a guide rod 6 and a lower frame plate 10, and two guide rods 6 is symmetrically arranged between the upper frame plate 3 and the lower frame plate 10 to form a fixed frame, the lifting cylinder 4 is fixed on the upper frame plate 3, one end of the lifting arm 5 is connected with the piston of the lifting cylinder 4, and the lifting arm 5 is connected with the marking machine casing 1 through lugs and pin shafts, and the marking machine casing 1 has guide holes, and the guide holes are guided in the guide rods 6 .

[0041] The marking machine casing 1 has a first side and a second side; the first axis 1.1, the second axis...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile modulus of elasticity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com